Overview

At Qualiss, our technicians recently completed Tube Bundle NDT Testing that included visual weld examination, dye penetrant testing, and hydrostatic pressure verification. This comprehensive inspection confirmed weld integrity and ensured the bundle’s readiness for safe operation.

We recently tested a fabricated tube bundle for service readiness. First, our inspectors completed a visual weld examination (VT). Next, we performed dye penetrant testing (PT) on critical welds. Finally, we conducted a hydrostatic pressure test to confirm pressure integrity. As a result, the owner received clear, code-compliant evidence that the bundle met the required performance and safety criteria.

Project Scope & Objectives

The client engaged Qualiss to independently verify weld quality and pressure containment before commissioning. Therefore, our scope focused on three stages:

Visual weld examination to assess workmanship and obvious discontinuities.

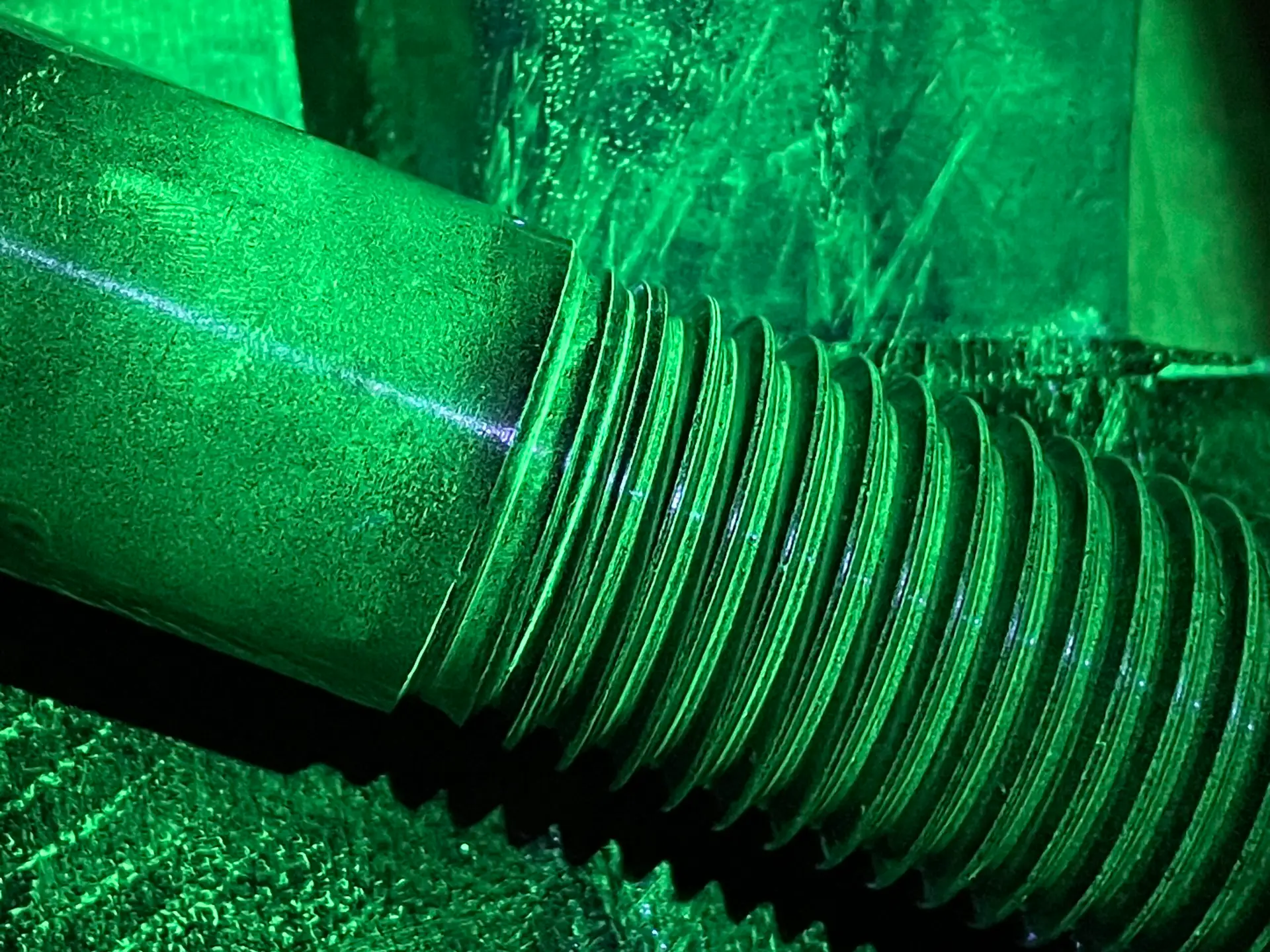

Dye penetrant testing to reveal surface-breaking cracks and porosity.

Hydrostatic testing to prove leak-tightness and structural integrity under pressure.

We worked under the client’s specifications and relevant Australian/industry standards. Moreover, we recorded each step with photos, measurement data, and signed test sheets for full traceability.

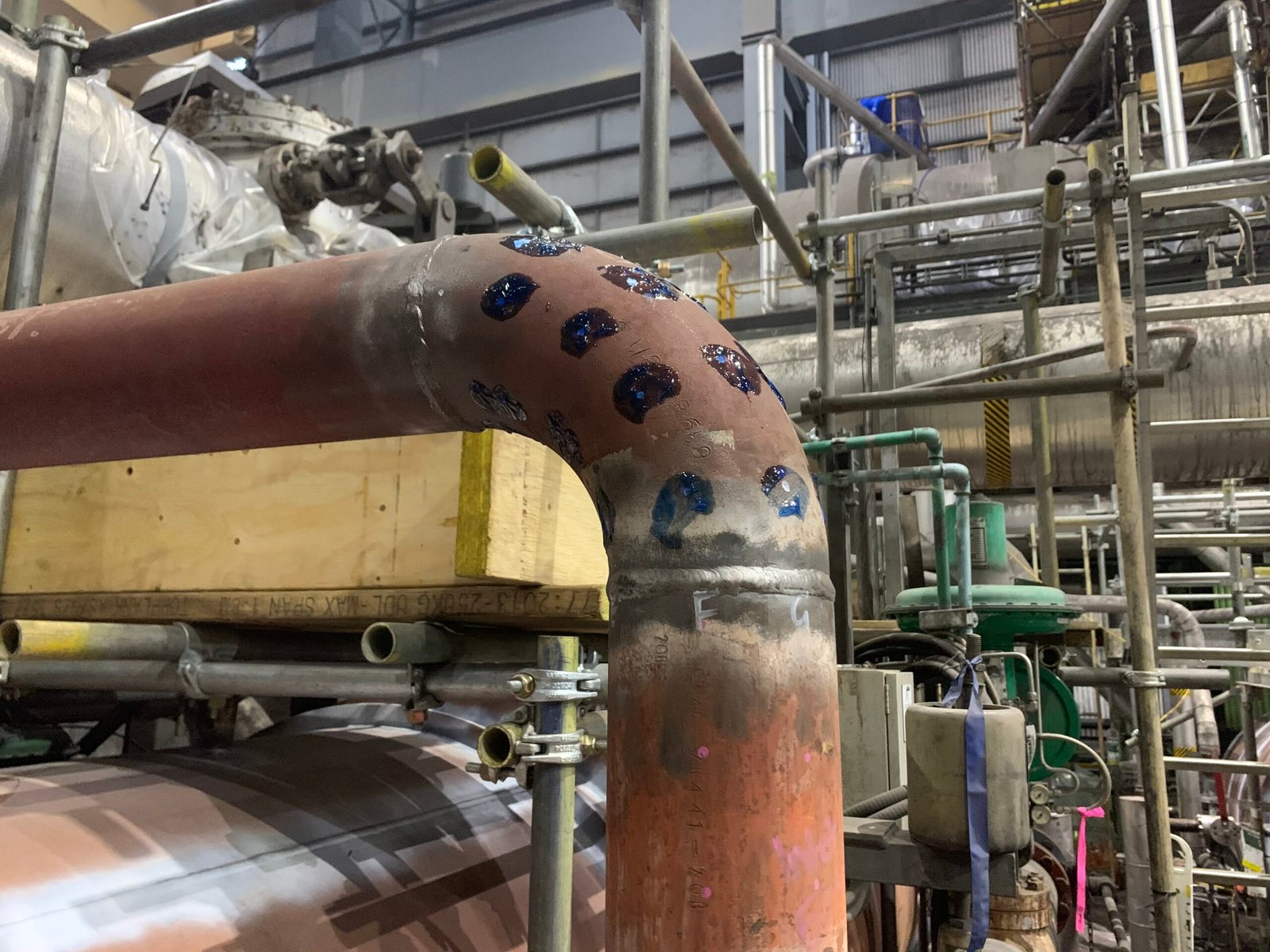

Step 1 — Visual Weld Examination (VT)

We began with a systematic visual inspection using bright white light, weld gauges, and surface prep where required. Specifically, we checked:

Weld profile, toe blending, and alignment

Undercut, overlap, arc strikes, and spatter

Heat tint and surface condition that could hide indications

Where we noted minor cosmetic issues, we asked the fabricator to address them before penetrant testing. This approach prevents false calls and, consequently, saves time during subsequent NDT.

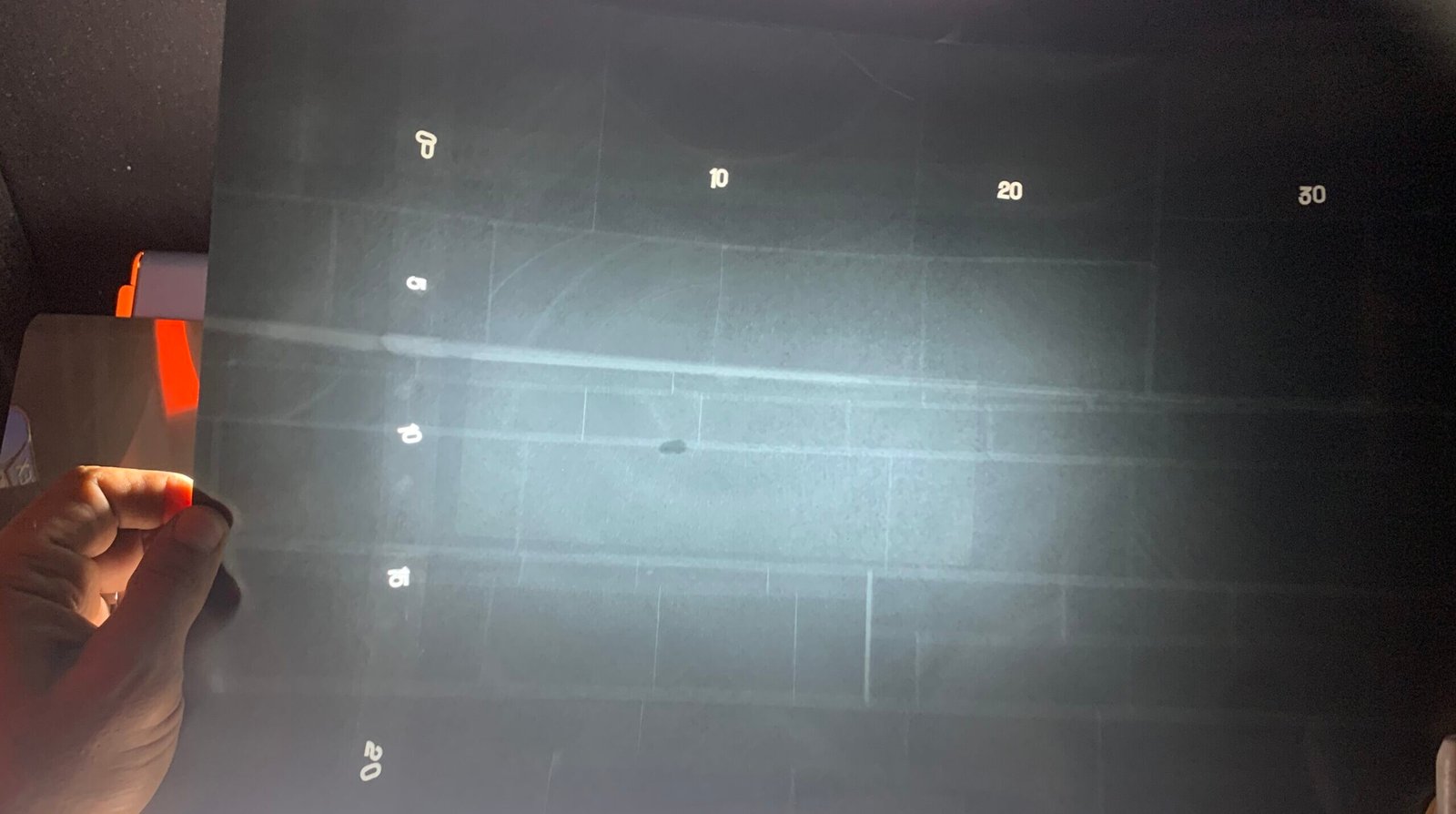

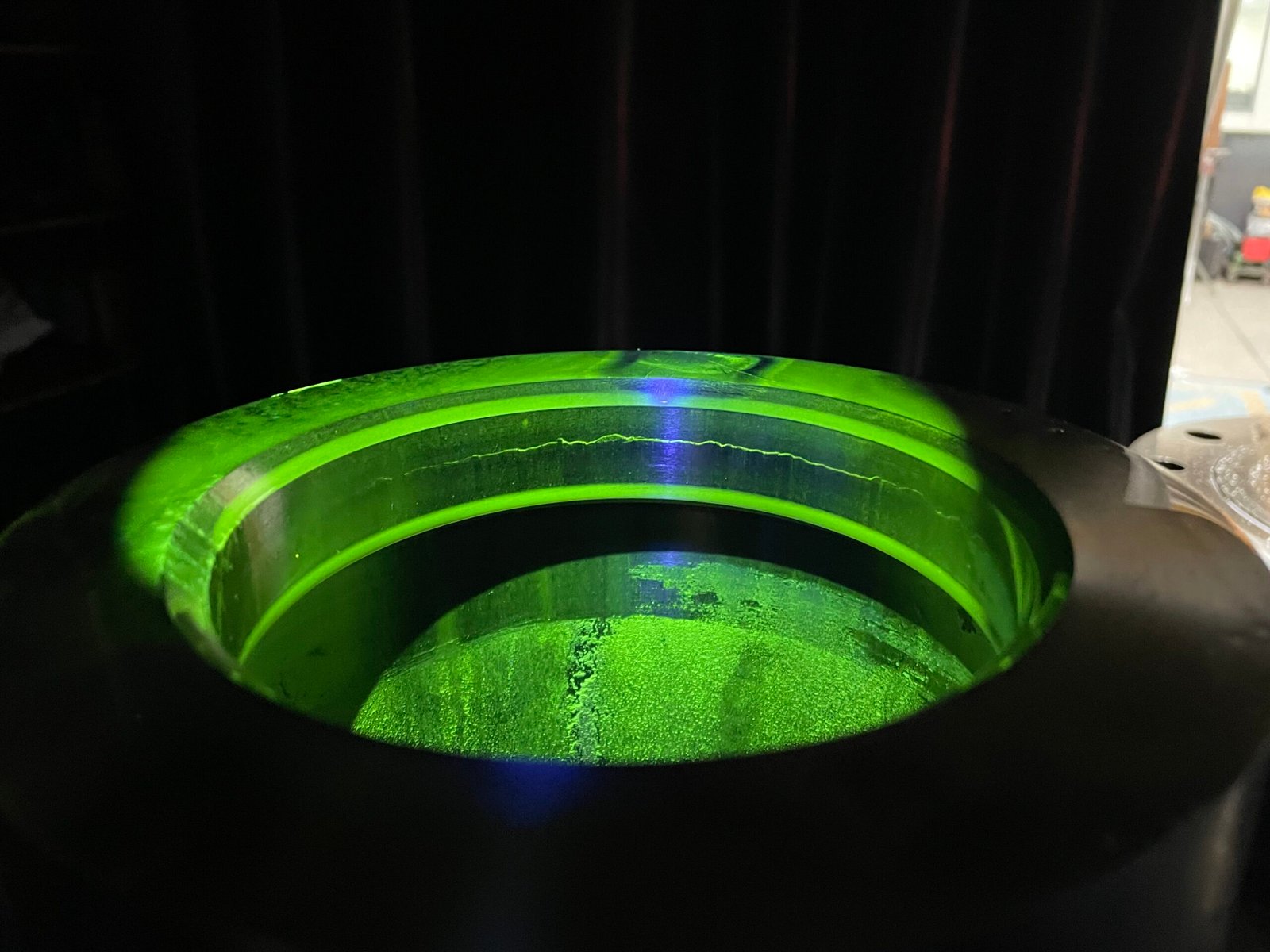

Step 2 – Dye Penetrant Inspection (PT)

After cleaning and drying the weld surfaces, we applied a visible red penetrant, observed the correct dwell time, and removed the excess with lint-free cloths. Then we applied developer to create high contrast.

Why PT here? Tube bundles often use stainless or non-magnetic alloys; therefore, PT is ideal for surface-breaking defects such as tight cracks, laps, or open porosity.

Outcome: We did not record any relevant PT indications on the examined welds. Consequently, we proceeded to hydrotesting with confidence.

Tip: Proper surface preparation improves sensitivity. In addition, correct dwell and development times reduce the risk of missed indications.

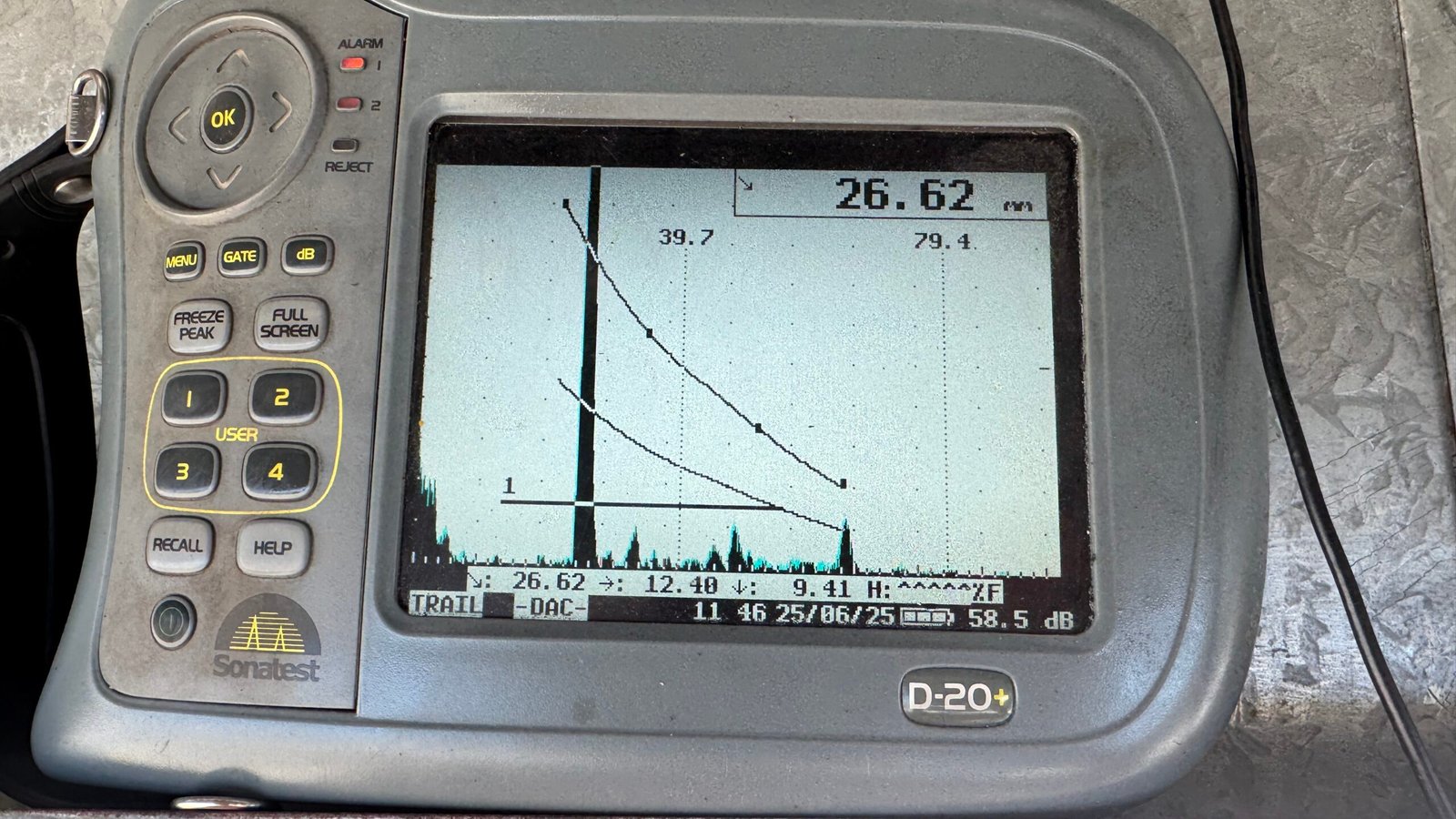

Step 3 – Hydrostatic Pressure Test

We prepared the assembly for a controlled hydrotest. First, we filled the system with water and bled all trapped air. Next, we gradually increased pressure to the specified test level (typically up to 1.5× design pressure, per project requirements). We held the pressure for the agreed duration while monitoring gauges and joints.

Acceptance criteria: No pressure drop outside tolerance, no seepage, and no permanent distortion.

Result: The bundle remained stable throughout the hold. Therefore, it met the acceptance criteria for pressure integrity.

Safety note: We always barricade the test area and use calibrated instruments. Additionally, we verify all relief and isolation steps before pressurising.

“Visual alone isn’t enough. PT and hydrotesting provide the evidence regulators and insurers trust.”

Why NDT Matters in Pressure Equipment Fabrication

Even the best-executed welds can hide subsurface flaws or fatigue risks.

By incorporating Visual, PT, and Hydrostatic Testing, Qualiss ensures:

✅ Defects are detected before commissioning

✅ Safety and reliability are verified under pressure

✅ Equipment meets or exceeds Australian standards

✅ Documentation satisfies third-party verification requirements

Regular NDT throughout fabrication not only ensures safety but also reduces long-term maintenance costs by preventing early failures.

Key Takeaways

Visual inspection confirms weld quality and workmanship.

Dye Penetrant Testing identifies fine surface cracks invisible to the naked eye.

Hydrostatic testing proves mechanical integrity and pressure retention.

Combined, these methods deliver full confidence in structural and process equipment integrity.

For code-compliant Tube Bundle NDT Testing, we align our methods with recognized guidance and standards, including Safe Work Australia’s plant safety framework, technician certification to ISO 9712 and non-destructive examination practices outlined in ASME BPVC Section V

Qualiss carried out a full inspection sequence including Visual Weld Examination (VT), Dye Penetrant Testing (PT), and a Hydrostatic Pressure Test. These methods verified weld quality, surface integrity, and pressure containment before commissioning.

PT is used to detect surface-breaking cracks, porosity, or laps that may not be visible to the eye. It’s ideal for stainless and non-magnetic alloys used in tube bundles, ensuring any surface defect is found before pressure testing.

Hydrotesting confirms that the system can safely handle its design pressure without leaks or deformation. The test is typically performed at 1.5× the design pressure to validate structural and weld integrity.

Only qualified and certified technicians—such as those certified under AS ISO 9712 or equivalent—should perform NDT. Qualiss technicians are fully qualified and operate under compliant procedures.

Testing is carried out in accordance with AS 4037, AS 4041, and relevant ASME Section V and IX standards. These govern weld inspection, non-destructive examination, and pressure testing for safe operation.

Inspection intervals depend on service conditions, pressure class, and regulatory requirements, but most pressure equipment requires periodic NDT and hydrotesting as part of its inspection and maintenance schedule.

Qualiss provides accurate, code-compliant inspection and testing across Queensland and Australia. With advanced NDT methods, certified technicians, and detailed reporting, we help clients verify integrity, reduce risk, and meet compliance requirements.