Inspection, Testing & Certification

Protecting Your Assets and Ensuring Compliance with Comprehensive Testing Services

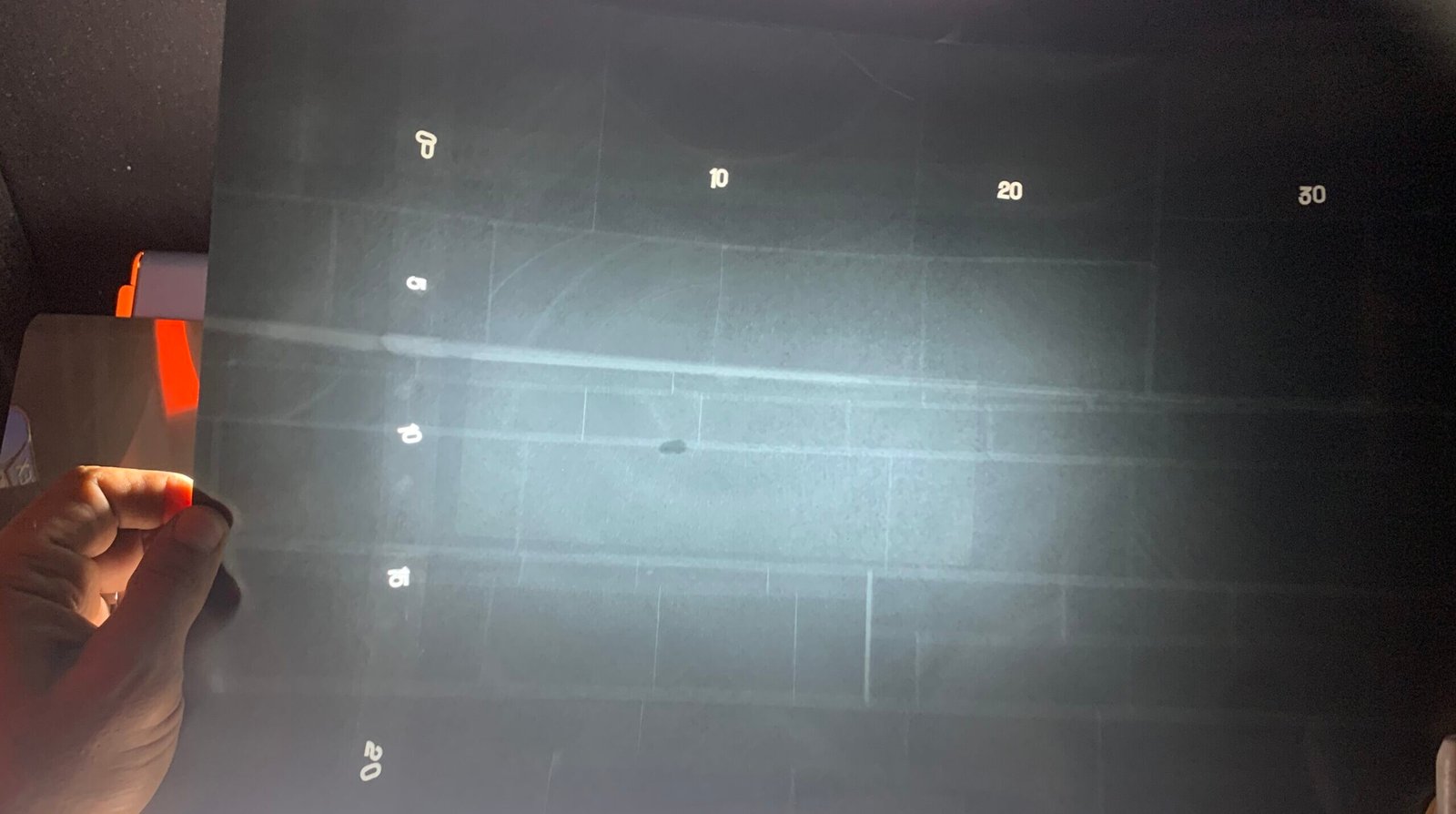

Digital Radiography

Fast, high resolution imaging for precise defect detection and instant results – minimising downtime while ensuring safety and compliance.

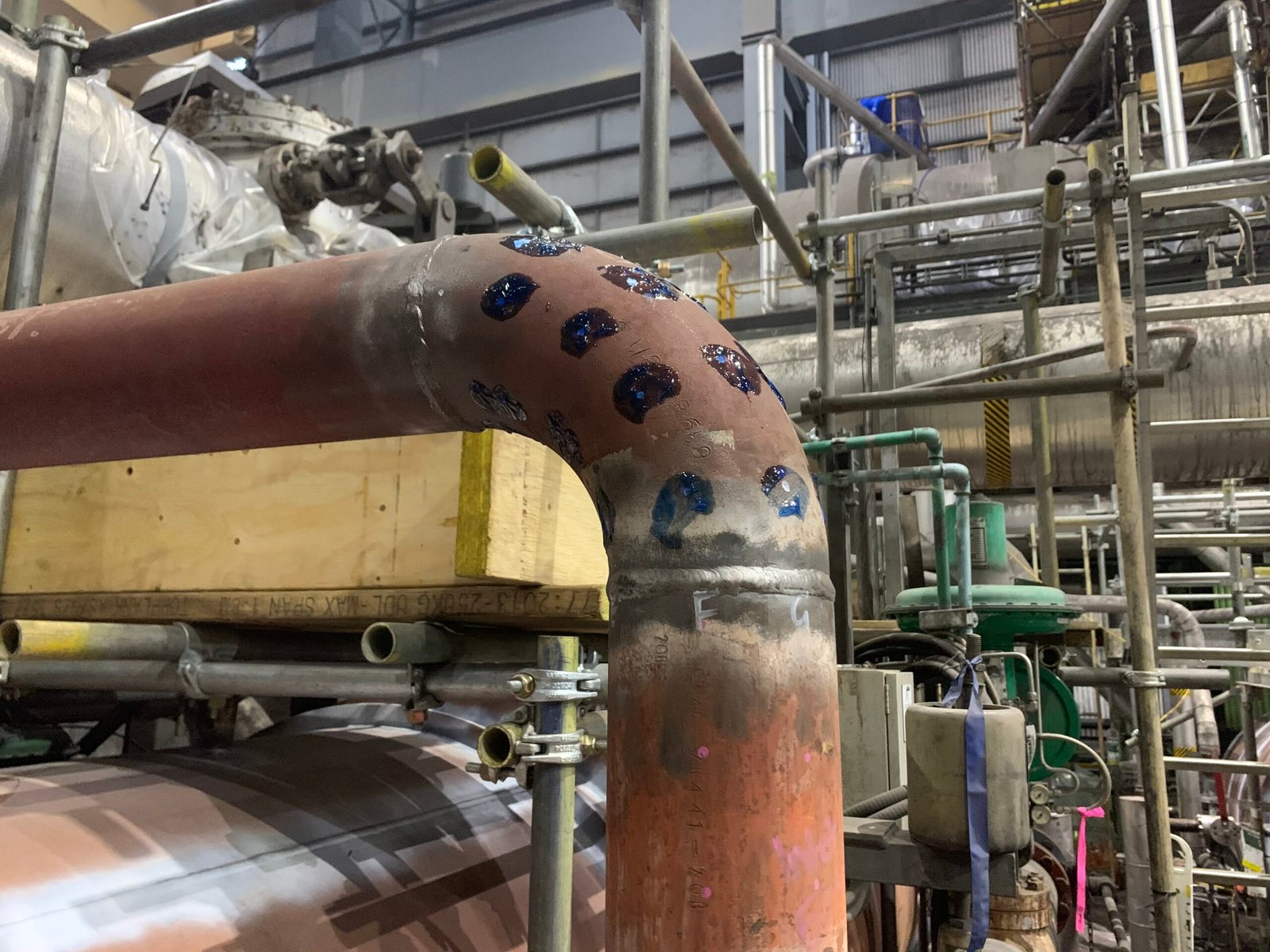

Dye Penetrant Testing

Quickly identify surface cracks, porosity, and other defects on metals and non-porous materials with precision. Dye Penetrant Testing provides a reliable, cost-effective method to detect flaws that could compromise safety or performance without the need for complex equipment or extensive downtime.

Boat Mast Inspection

Your boat’s mast is the backbone of its rigging system – any hidden flaw can put performance and safety at risk. Our specialised mast inspection services use advanced testing techniques to detect cracks, corrosion, and structural weaknesses before they become costly or dangerous.

Unmatched Expertise

Certified technicians with proven experience across marine, industrial, and infrastructure sectors.

Cutting-Edge Technology

Advanced NDT methods including LRUT, MRUT, digital radiography, and high-voltage pole testing.

Proven Track Record

Trusted by leading Australian industries for accurate, timely, and compliant inspection results.

Client-First Approach

Tailored solutions, clear reporting, and dedicated support from start to finish.

Efficient, Reliable Non-Destructive Testing for Assets

Who we are

Our expertice

Principles of our work

Who we are

At Qualiss, we specialise in inspection, testing, and certification services that ensure the safety, quality, and compliance of your assets. Our team of qualified technicians combines industry expertise with advanced technology to deliver accurate results, clear reporting, and dependable solutions.

We work across marine, industrial, and Oil and Gas sectors, providing services such as ultrasonic testing, digital radiography, and non-destructive examination. With a commitment to precision, safety, and customer service, we partner with you to protect your investments and keep operations running smoothly.

Our expertice

At Qualiss, our expertise spans a full range of advanced inspection and testing methods, ensuring your assets meet the highest safety and quality standards. We combine accredited procedures, cutting-edge technology, and experienced technicians to deliver precise, reliable results.

Principles of our work

Safety First

We prioritise the safety of people, assets, and the environment in every inspection and test we perform.

Accuracy & Reliability

Our results are precise, repeatable, and backed by accredited procedures.

Innovation

We embrace the latest technology to deliver faster, more efficient, and more insightful outcomes.

Transparency

We embrace the latest technology to deliver faster, more efficient, and more insightful outcomes.

Client Focus

We embrace the latest technology to deliver faster, more efficient, and more insightful outcomes.

These principles underpin everything we do, ensuring your projects are completed to the highest industry standards.

Non-Destructive Testing Solutions Designed for Your Business

Get a Quote for Your Inspection Needs

TRaditional NDT Services

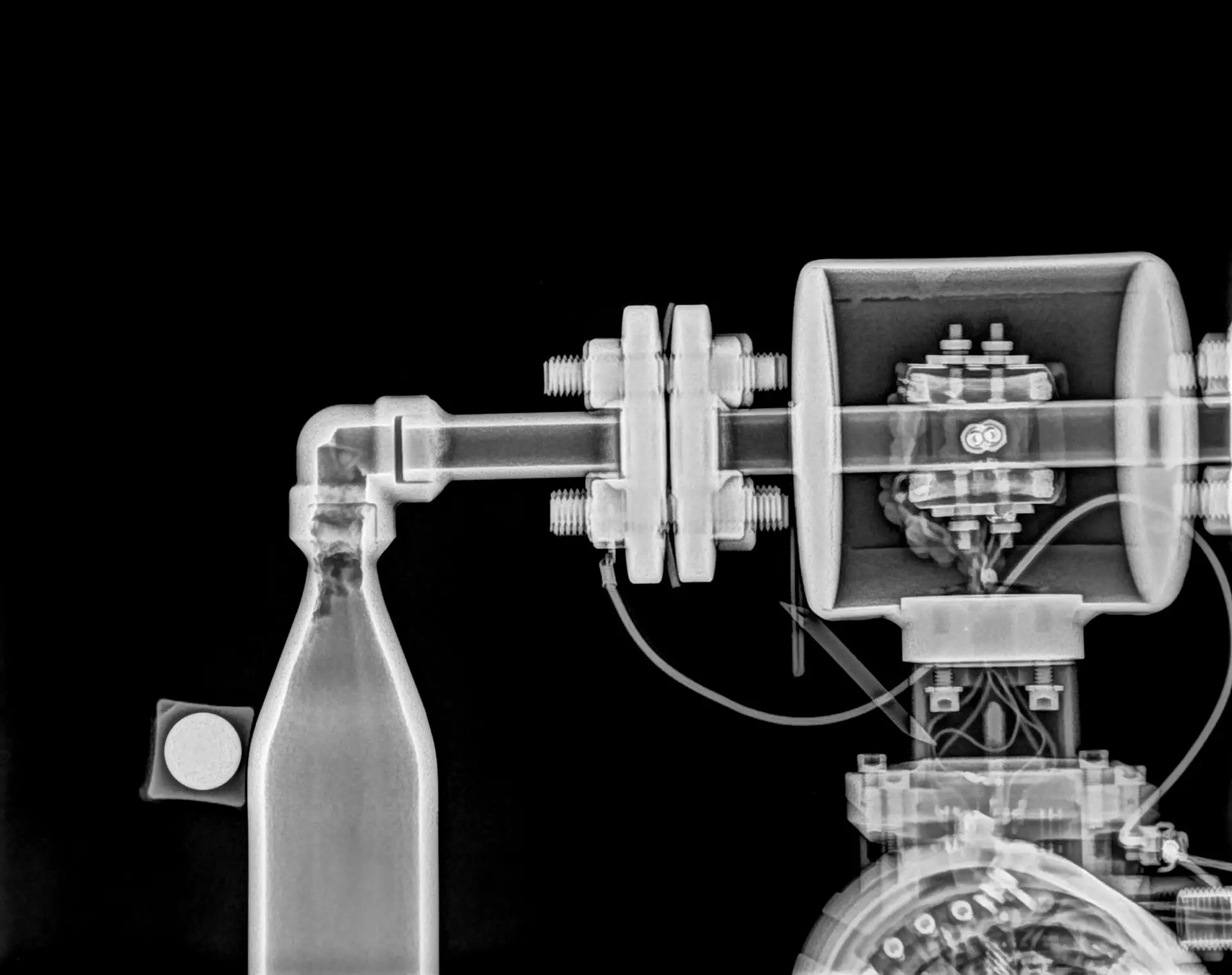

Traditional Radiography (RT)

Using X-ray or gamma ray technology, we inspect welds, castings, and structural components to reveal internal defects that cannot be detected visually. Our radiographic testing delivers highly accurate results, ensuring compliance with industry standards while minimising disruption to your operations.

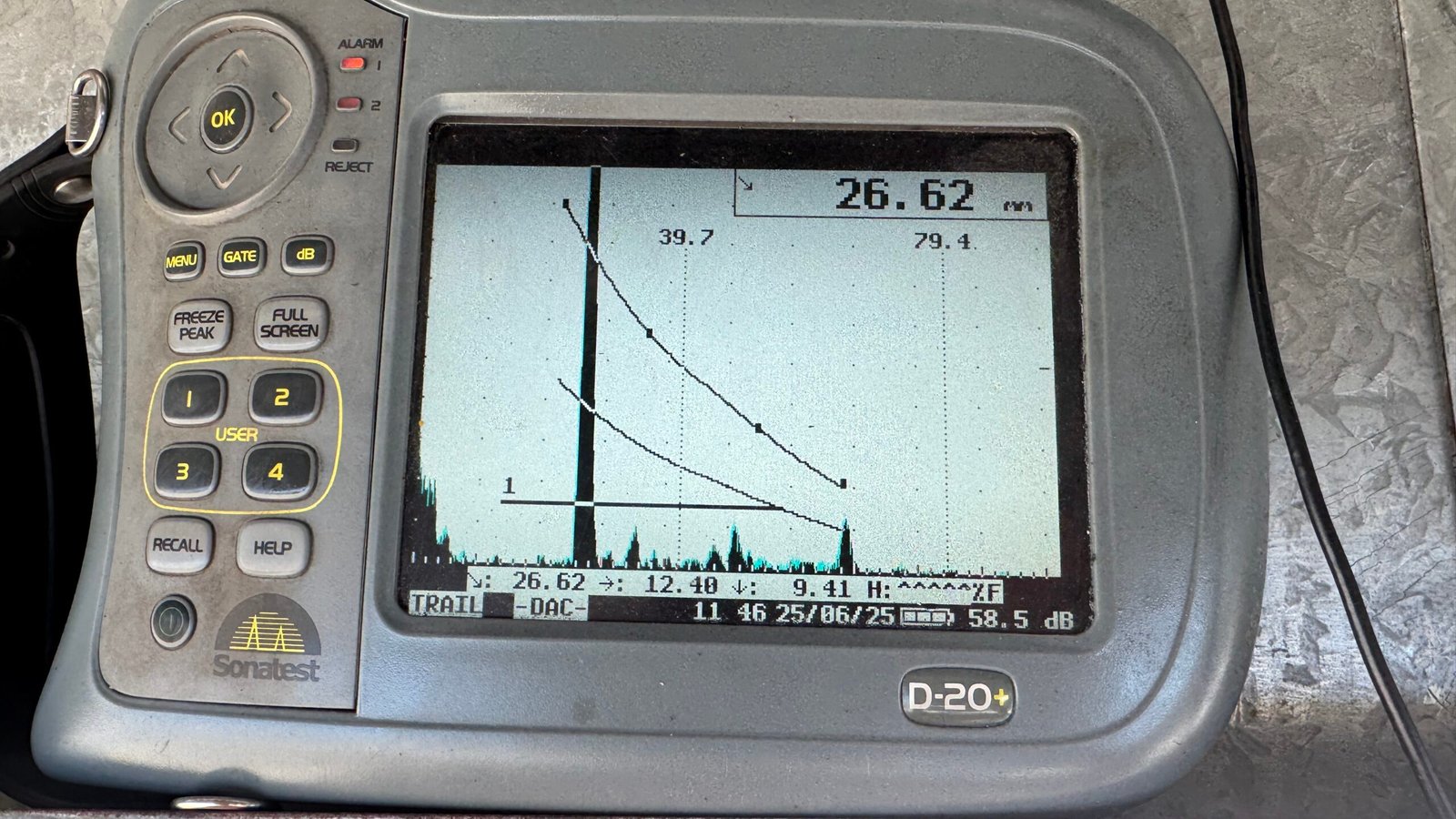

Ultrasonic Testing (UT)

Using high-frequency sound waves, we accurately detect internal flaws and measure material thickness in metals, composites, and other equipment. Ultrasonic testing allows precise in-service inspections without the need for internal access, ensuring asset integrity and compliance with minimal downtime.

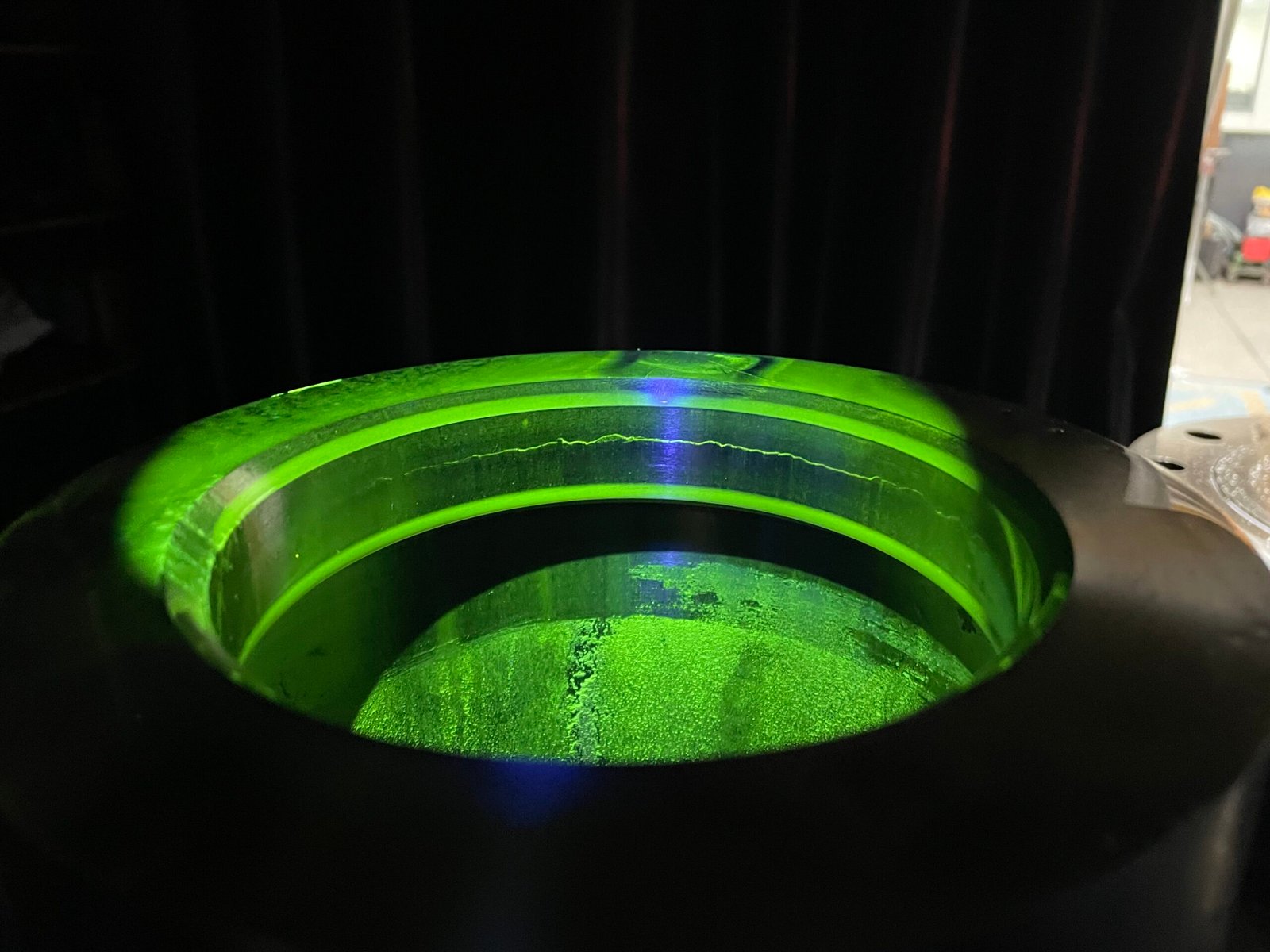

Magnetic Particle Testing (MT)

Applying a magnetic field and fine iron particles, we reveal surface and near-surface defects in ferromagnetic materials. This method is highly effective for weld integrity checks, delivering fast, reliable results to maintain safety and compliance in critical components.

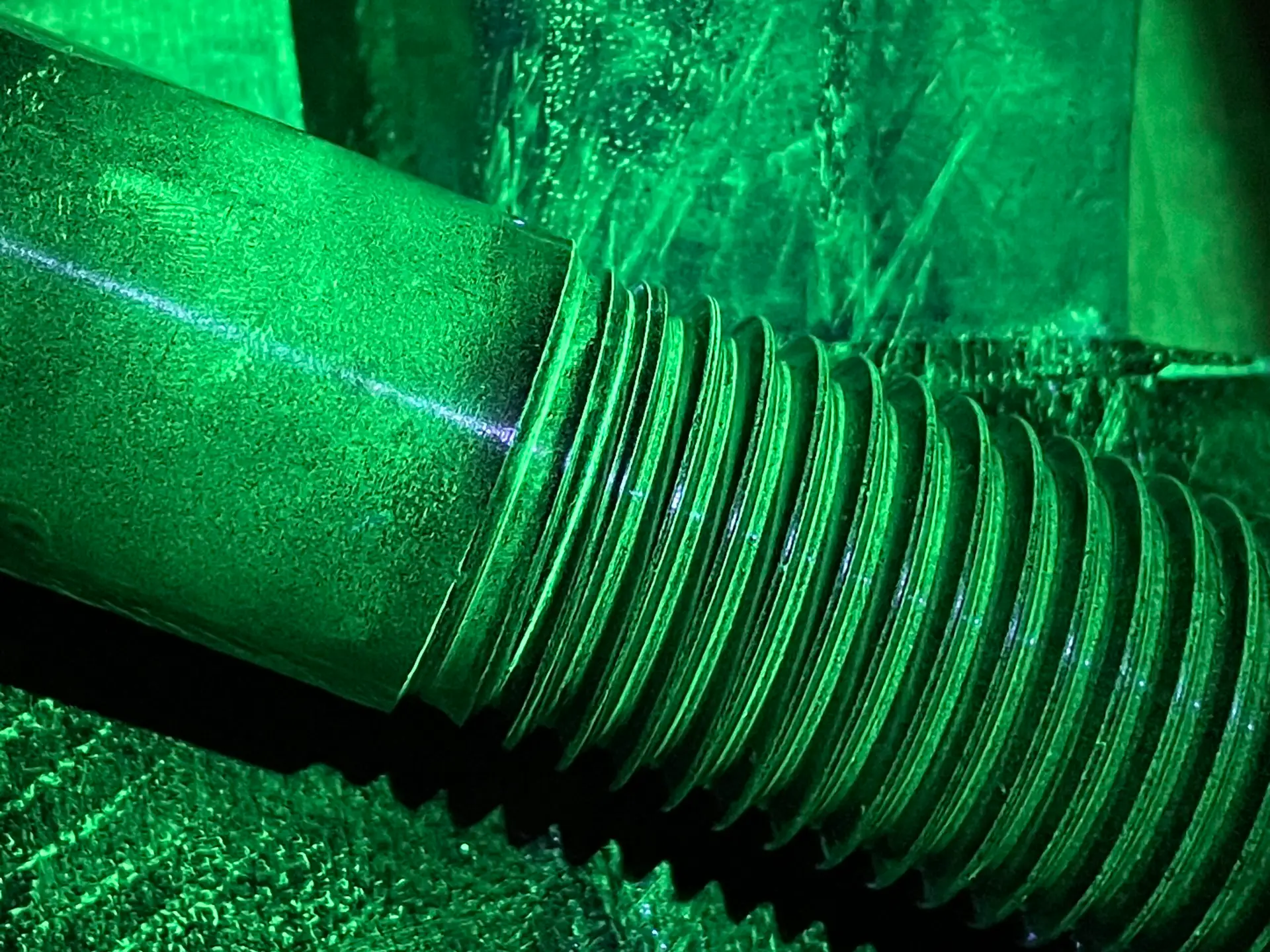

Penetrant Testing (PT)

By applying visible or fluorescent dye to non-porous materials, we identify fine cracks, porosity, and surface-breaking flaws that may otherwise go undetected. Penetrant testing is a cost-effective, accurate method for ensuring product quality and structural safety.

Eddy Current Testing (ECT)

Using electromagnetic induction, we detect surface and near-surface flaws in conductive materials, measure coating thickness, and assess material properties. Eddy current testing is fast, accurate, and requires minimal surface preparation, making it ideal for aircraft, marine, and industrial applications.