Cracking the Truth: Testing Stellite Welds with Magnetic Particle & Dye Penetrant Inspection

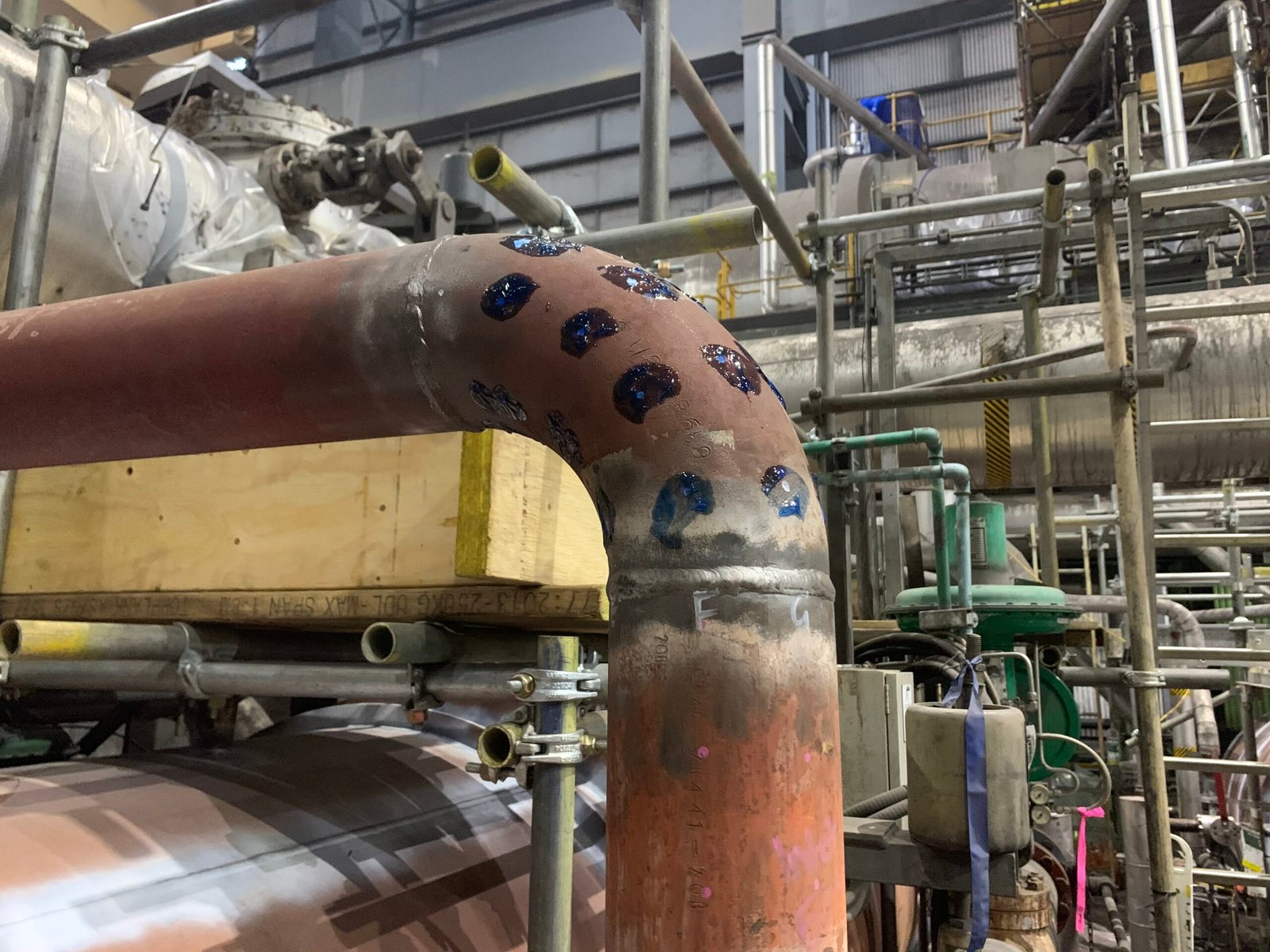

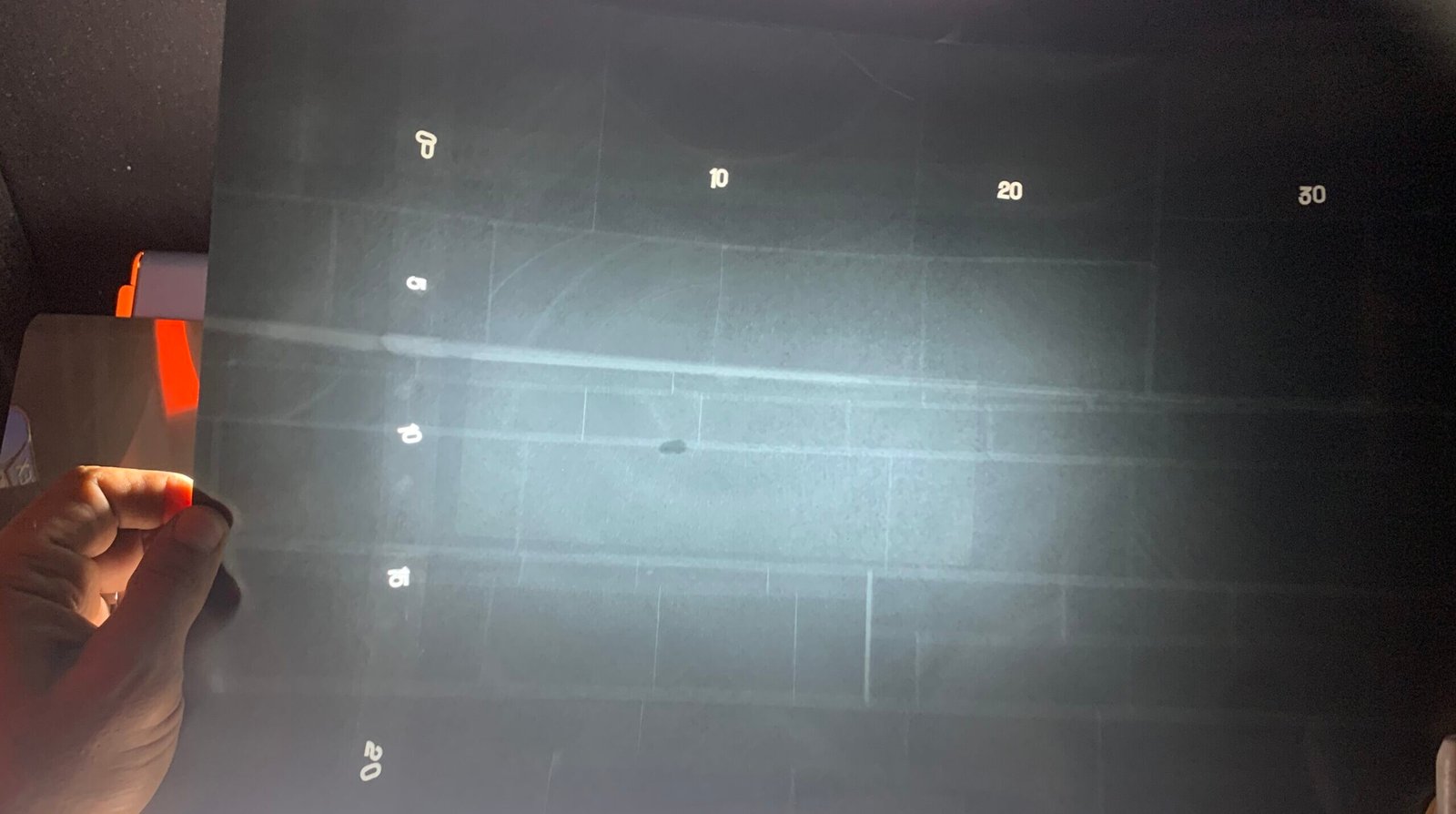

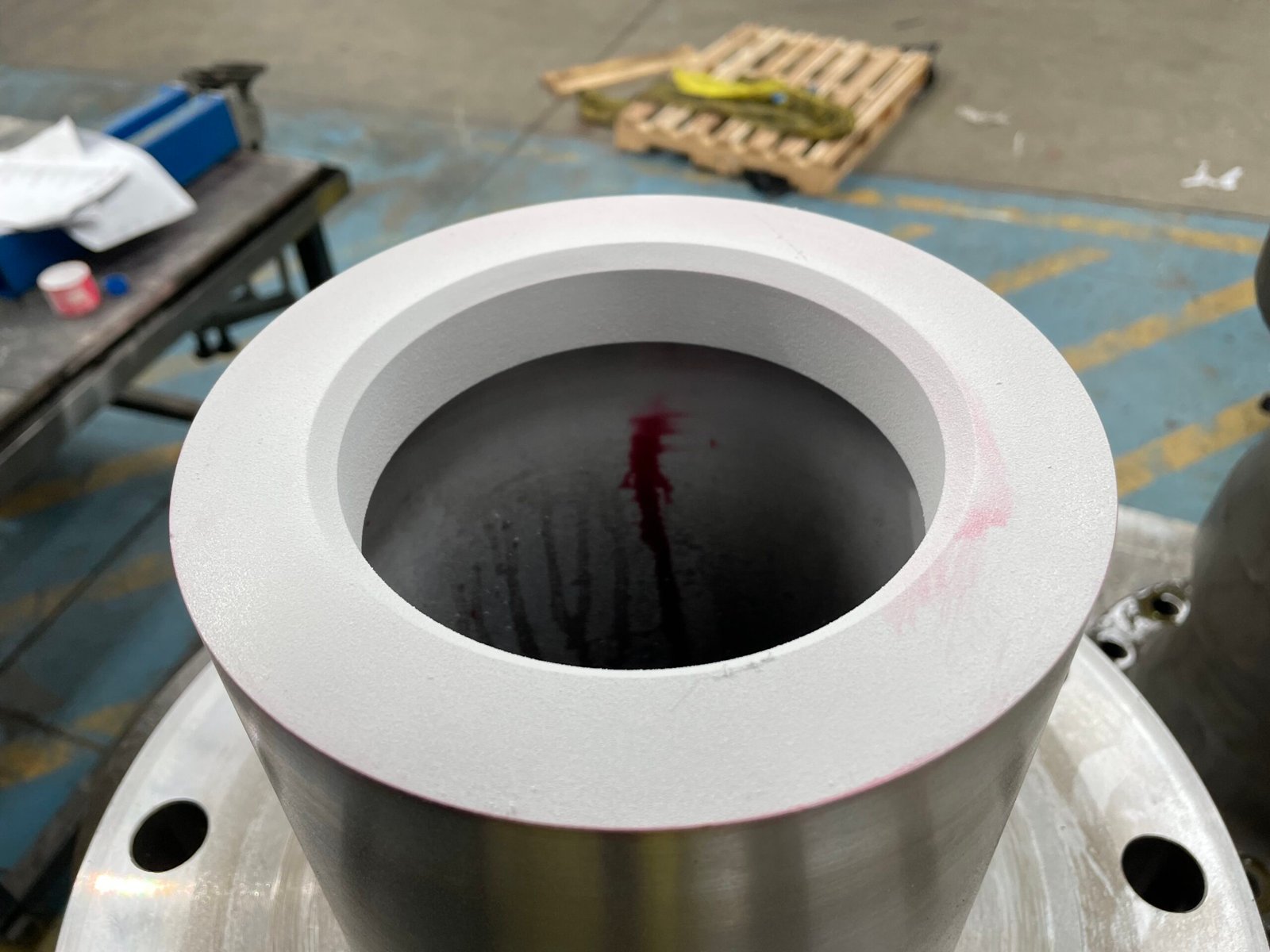

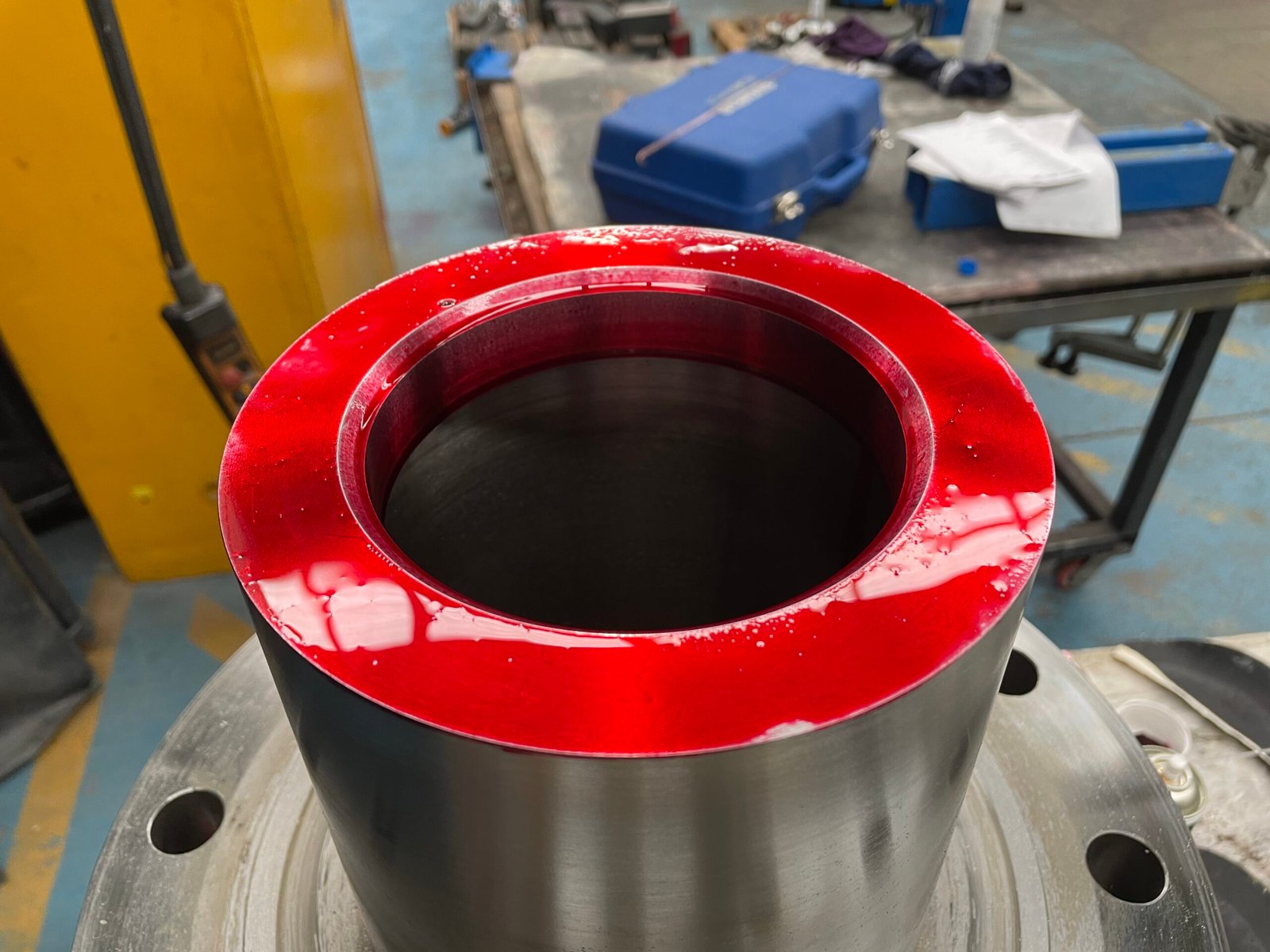

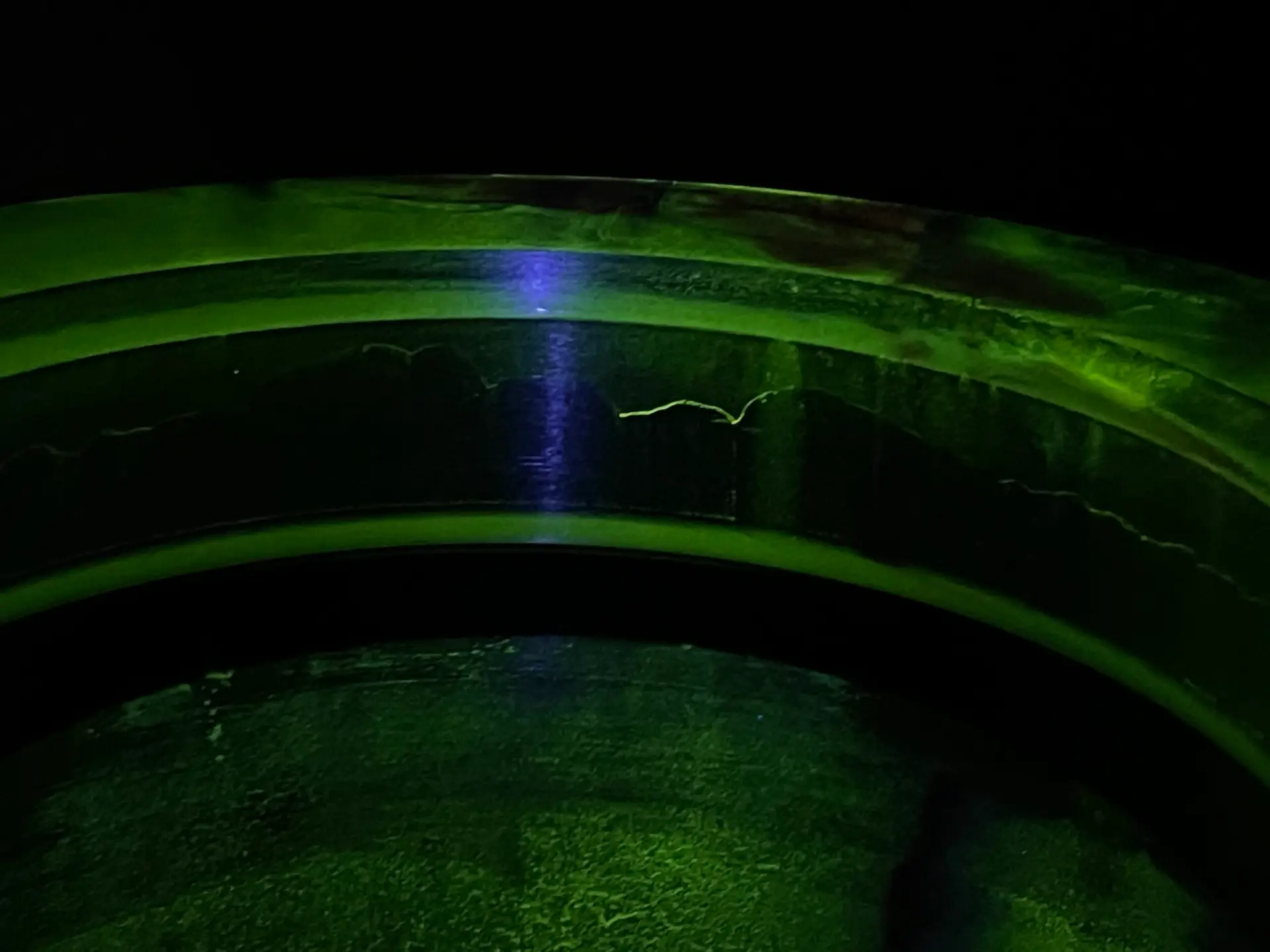

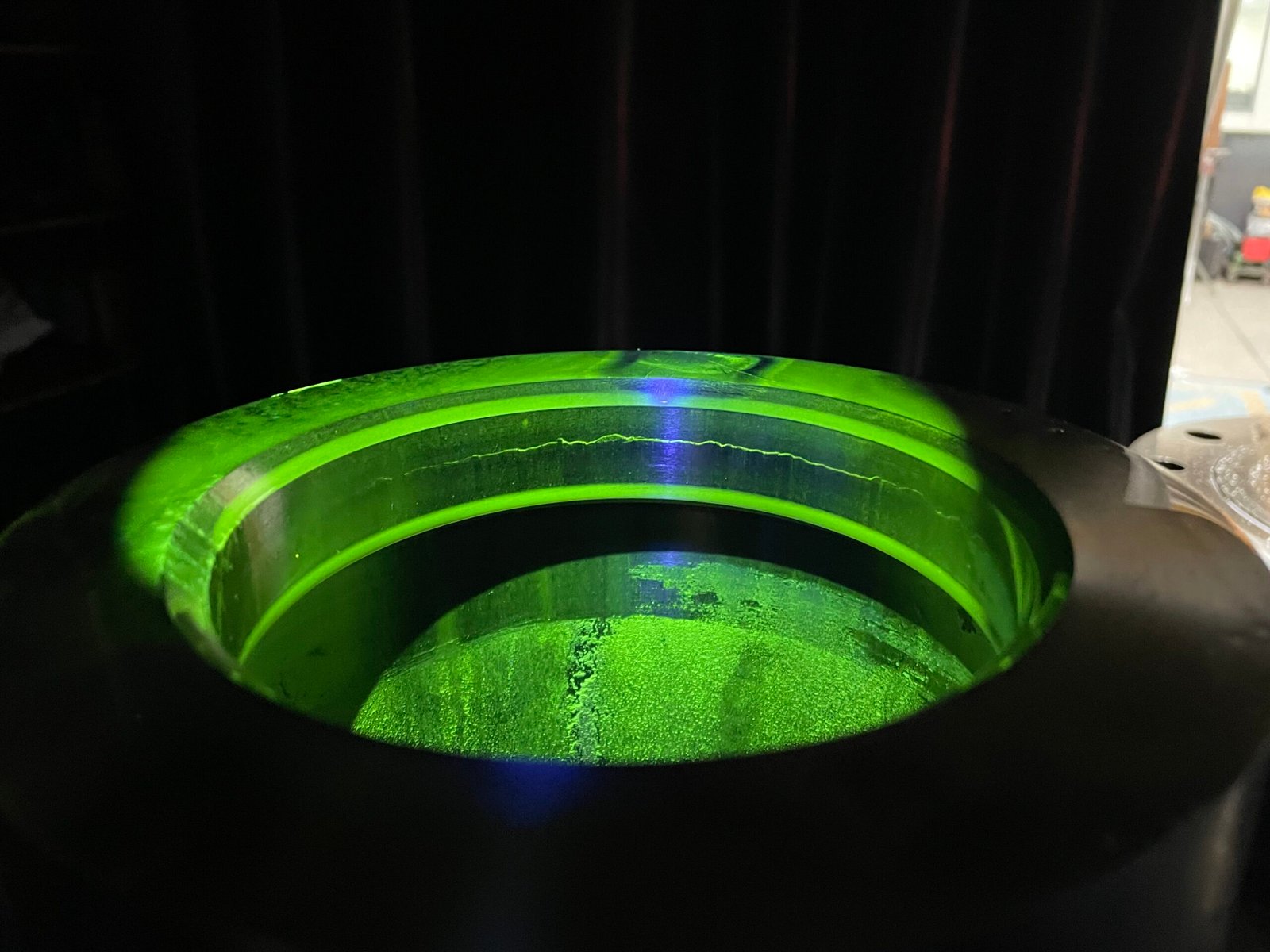

When it comes to welding Stellite to mild steel, inspection isn’t always straightforward. Recently, during a routine inspection, our team at Qualiss tested a Stellite weld using Magnetic Particle Inspection (MPI). The results showed several linear indications that looked like cracks.

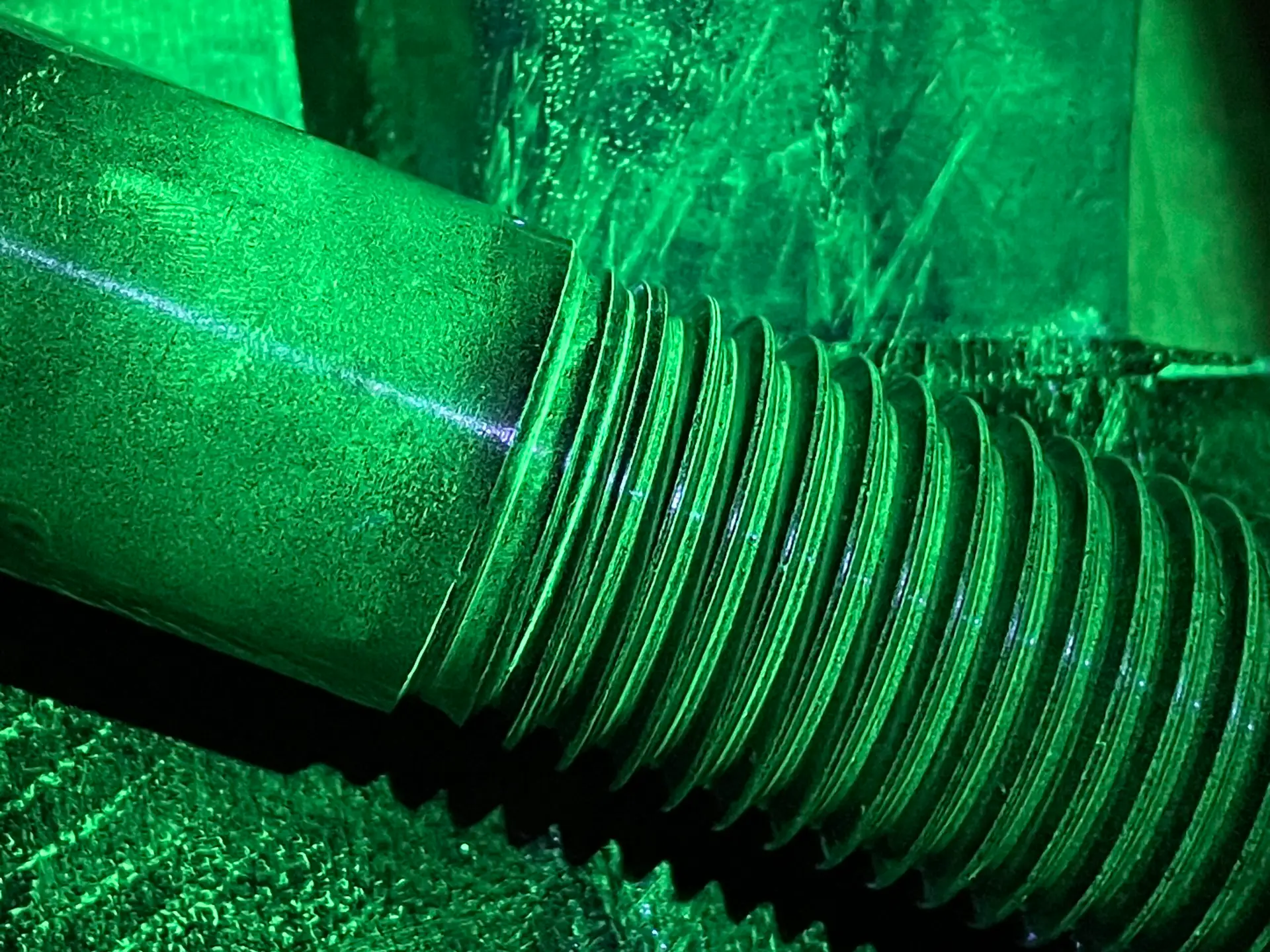

But instead of raising an alarm, we dug deeper. We followed up with Dye Penetrant Inspection (DPI) — and found no actual cracks present. This is a perfect example of why choosing the right NDT method matters.

Why Stellite Welds Are Tricky to Test

Stellite is a cobalt-based hard-facing alloy used for wear and corrosion resistance. It’s often welded onto mild steel substrates for durability. However, this welding combination creates a grain structure mismatch at the fusion zone.

Here’s the challenge:

MPI is sensitive to grain boundaries. These can produce false crack indications when Stellite meets mild steel.

The result? A weld may appear cracked when in fact it’s structurally sound.

MPI vs DPI – Understanding the Difference

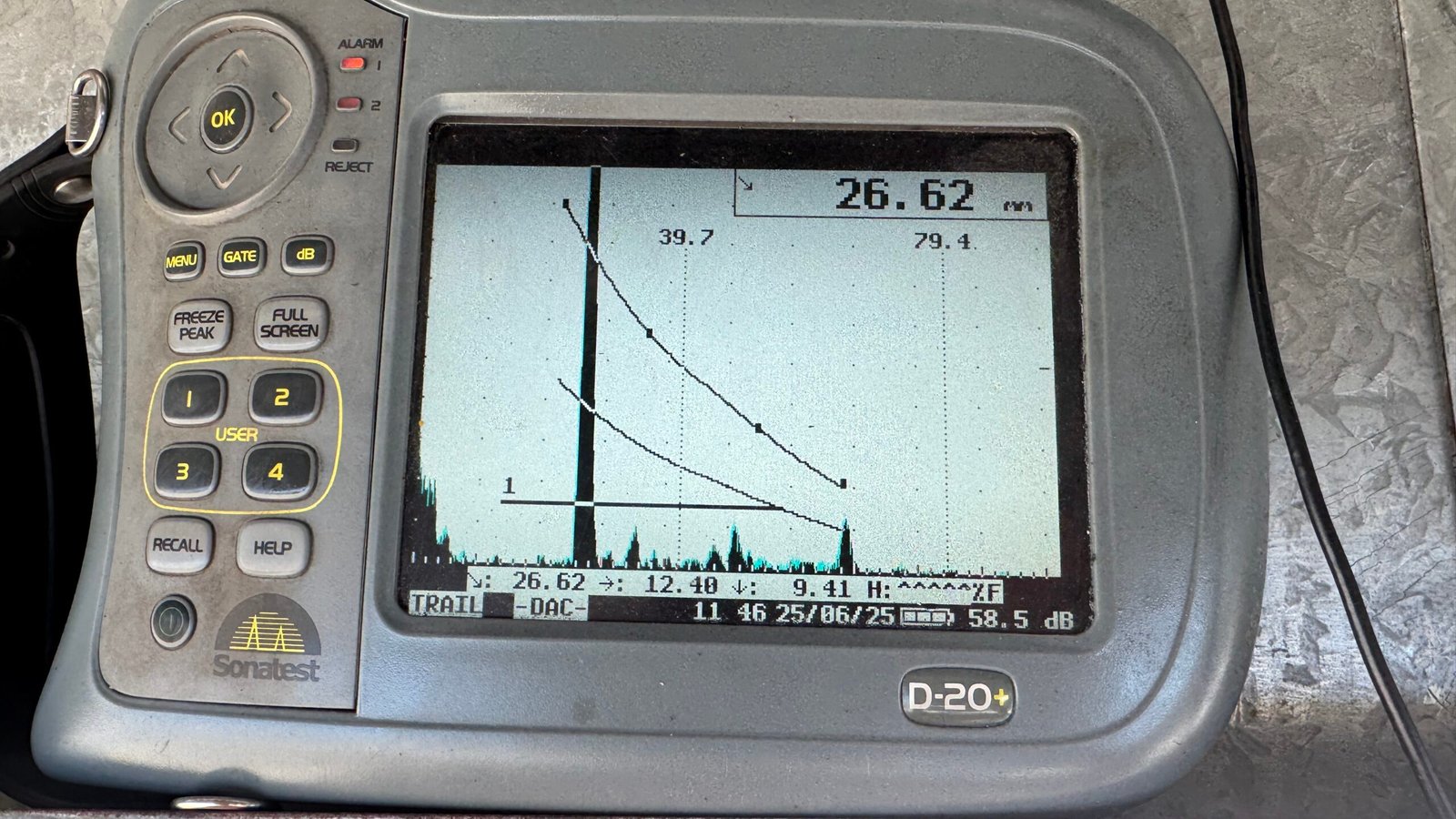

Magnetic Particle Inspection (MPI)

Great for detecting surface and near-surface cracks in ferromagnetic materials (like mild steel).

Fast, portable, and widely used.

But on Stellite welds, the fusion zone grain structure can trick MPI into showing false cracks.

Dye Penetrant Inspection (DPI)

Works by drawing penetrant liquid into any true surface-breaking defects.

Doesn’t rely on magnetism, making it ideal for non-ferromagnetic alloys like Stellite.

Provides a clear yes/no result for surface cracks.

The Best Approach: Dual Inspection

From our inspection, one thing is clear:

MPI is still valuable for checking the steel substrate around the weld.

DPI is essential on the Stellite weld surface and fusion line for accurate results.

By combining both, you get the full picture: speed and sensitivity from MPI, plus reliability and clarity from DPI.

“MPI on Stellite welds may produce false indications. Penetrant Testing provides accurate confirmation of surface cracks, porosity, or lack of fusion”

Why This Matters for Your Business

If a weld is misdiagnosed as cracked, it could lead to:

Unnecessary repairs costing time and money.

Delays in service when equipment is wrongly flagged as unsafe.

Loss of confidence in asset integrity.

On the other hand, missing a genuine crack can be catastrophic. That’s why experience and correct method selection are everything in NDT.

Not every indication is a crack. With Stellite welds on mild steel, MPI alone can mislead, but using DPI in combination confirms the truth. At Qualiss, our approach saves clients from unnecessary repairs, while ensuring safety and reliability remain uncompromised.

👉 Looking for weld inspection that goes beyond a surface result? Contact Qualiss today and let us protect your assets with expert NDT services.