What Is IRIS Tube Testing?

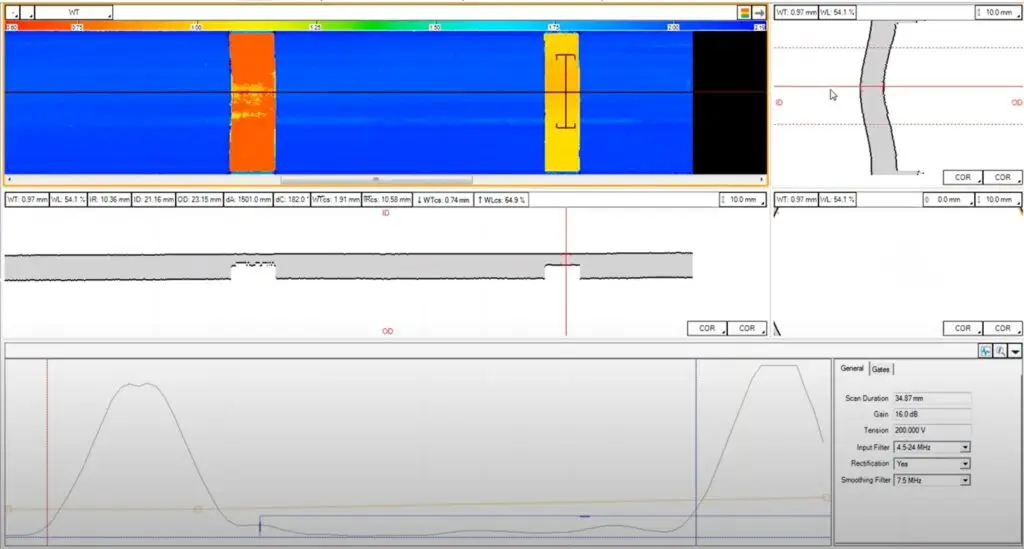

IRIS (Internal Rotary Inspection System) uses a rotating ultrasonic probe inserted into tubes to provide high-resolution, volumetric data—ideal for identifying internal defects and measuring wall thickness. Perfect for heat exchangers, boilers, and similar equipment.

Why Choose IRIS Tube Testing?

Accurate & Comprehensive: Captures detailed internal data, including corrosion and deposit build-up.

Minimal Downtime: Conduct inspections without tube removal or extensive dismantling.

Quantitative Results: Provides precise wall thickness measurements for trend analysis.

Nondestructive & Safe: No damage to assets; safe, efficient testing.

Cost-Effective: Save on maintenance and prevent unexpected failures with early detection.

Typical Applications

Heat exchanger tubes

Boiler tubes

Condensers and shell-and-tube heat exchangers

Industrial piping systems

Offshore and marine equipment

How It Works – Step-by-Step

Preparation: Isolate and clean the tube, removing scale and deposits.

Probe Insertion: Introduce the rotating ultrasonic probe at one end of the tube.

Data Collection: Capture continuous ultrasonic data while retracting the probe.

Analysis: Identify corrosion, erosion, and wall-loss areas via high-resolution readings.

Reporting: Receive comprehensive reports, including defect location, measurement data, and recommended maintenance actions.

Limitations of IRIS Tube Testing

Requires Clean Tubes – Scale, sludge, or heavy deposits must be removed before testing for accurate results.

Time-Intensive Setup – Cleaning and water filling can add to inspection time compared to some electromagnetic methods.

Water Couplant Needed – IRIS testing requires tubes to be filled with water, which may not suit all environments.

Surface-Only Defects – Very small surface cracks or tight flaws may be better detected using complementary methods like Eddy Current Testing (ECT).

Accessibility – IRIS probes must fit inside the tube; very small diameters or blocked tubes may not be testable.