What Services We Provide

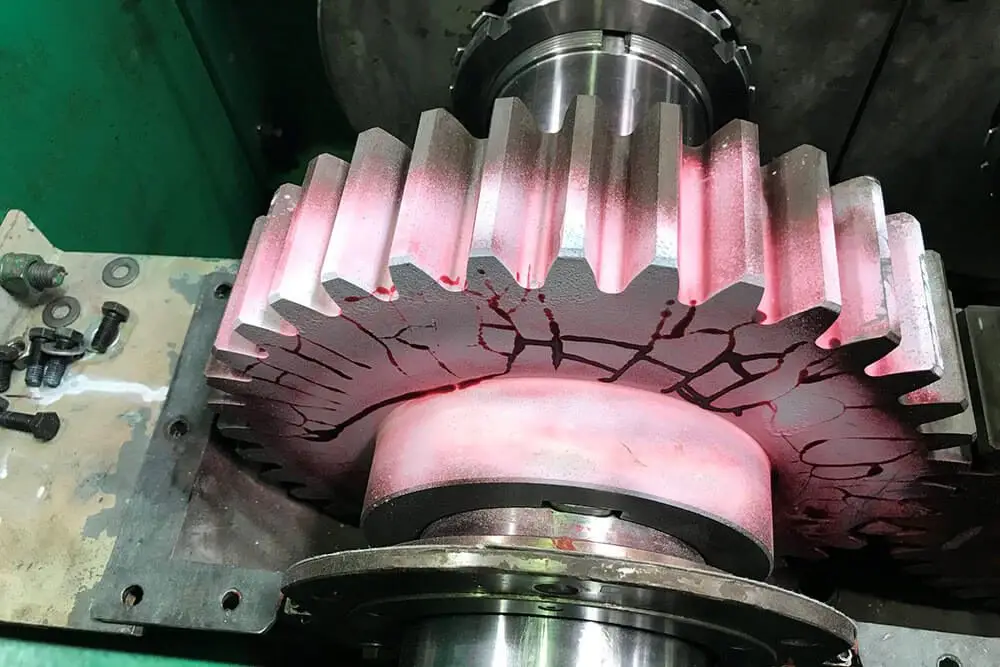

Dye Penetrant Testing (PT) is a non-destructive testing method used to identify surface breaking defects in non porous materials. At Qualiss, we employ advanced PT techniques to ensure the integrity and safety of your assets.

Key Benefits:

High sensitivity to surface-breaking defects.

Cost-effective and straightforward application.

Suitable for a wide range of materials and geometries.

Quick turnaround with minimal downtime.

Key Benefits:

High sensitivity to surface-breaking defects.

Cost-effective and straightforward application.

Suitable for a wide range of materials and geometries.

Quick turnaround with minimal downtime.

Applications

Marine structures (e.g., hulls, masts, rigging)

Industrial equipment and machinery

Pressure vessels and pipelines

Aerospace components

Our Process

Step 1: Surface Preparation – Cleaning the test area to remove contaminants.

Step 2: Application of Penetrant – Applying a visible or fluorescent dye to the surface.

Step 3: Excess Penetrant Removal – Removing the excess dye to reveal any defects.

Step 4: Developer Application – Applying a developer to draw out the penetrant from any defects.

Step 5: Inspection – Examining the surface under appropriate lighting conditions.

Limitations

Only works on surface-breaking flaws.

Surface must be clean and free from coatings.

Best suited for non-porous materials.