Digital Radiography Services Australia

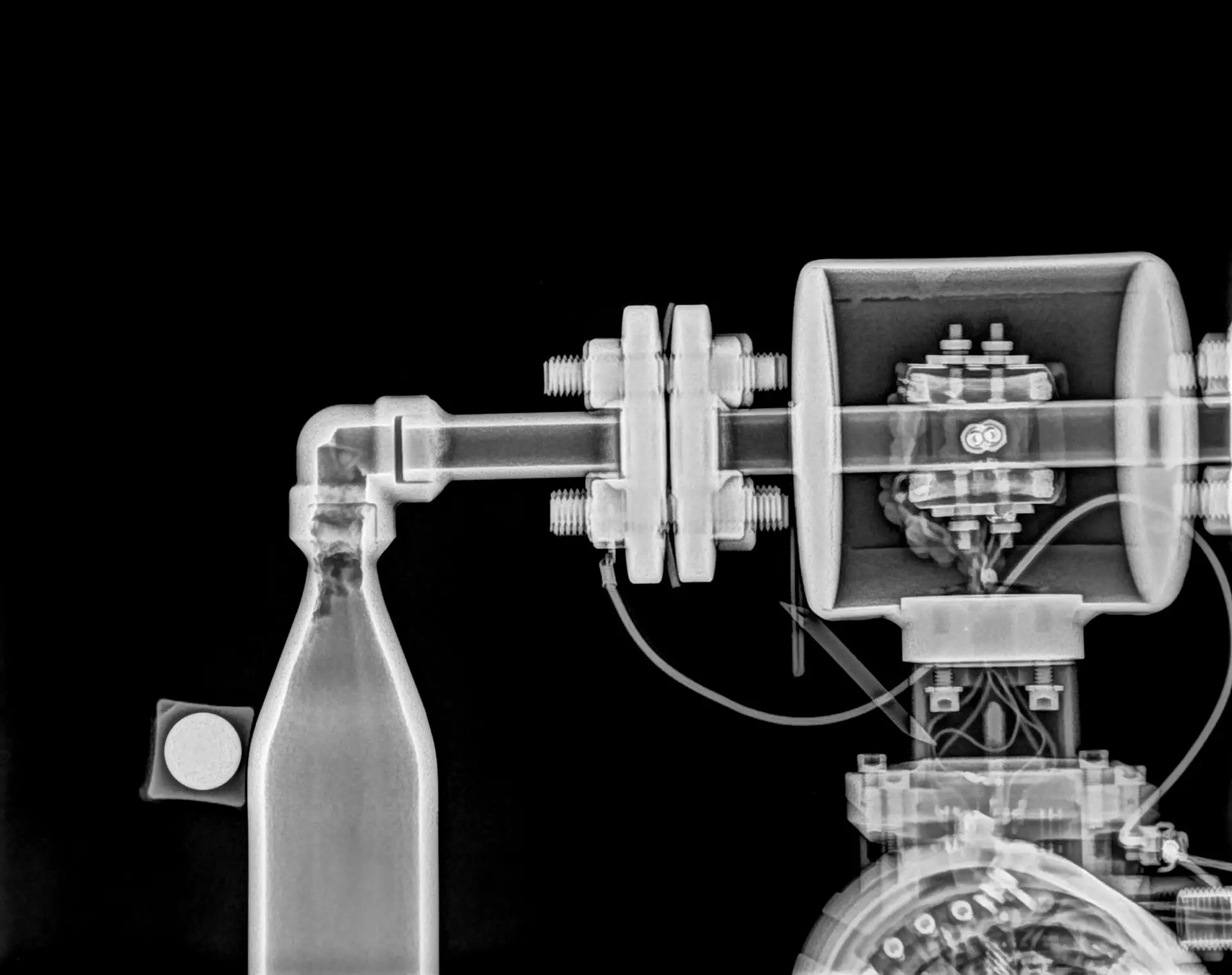

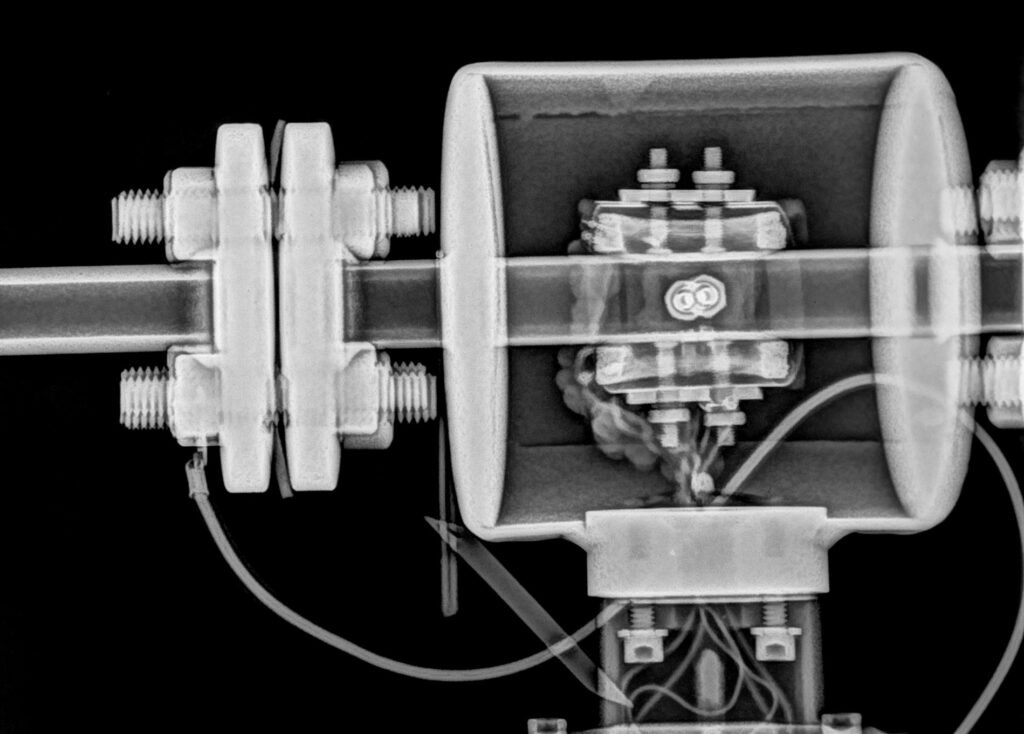

At Qualiss, we provide expert digital radiography services in Australia. Our advanced non-destructive testing (NDT) methods allow businesses to detect internal defects in welds, pipes, and critical components with unmatched accuracy. Moreover, our DR inspections deliver fast results, reduce downtime, and support compliance with national and international standards.

Why Choose Digital Radiography?

Digital Radiography (DR) is a modern NDT technique that uses digital X-ray sensors instead of traditional film. As a result, it offers immediate, high-resolution images that allow for precise defect detection and improved reporting.

Key benefits include:

Instant image preview for rapid analysis

Reduced radiation exposure for safer inspections

Superior image quality for detecting weld and structural defects

Digital storage and easy sharing for compliance and record-keeping

Internal Link: Learn more about our Ultrasonic Testing Services

Applications & Benefits

Qualiss provides DR inspections across a wide range of industries and applications, including:

Weld Inspections: Detect internal flaws in structural and pressure welds.

Piping and Pressure Vessels: Assess wall thickness and identify corrosion or erosion patterns.

Aerospace Components: Ensure structural integrity of critical parts.

Manufacturing Quality Control: Inspect castings, fabricated components, and industrial parts.

Outbound Link: For Radiation safety standards, see Arpansa

Our Approach at Qualiss

Collaborative Needs Assessment

We tailor the inspection based on your asset, environment, and regulatory requirements.Precision Imaging and Analysis

Using calibrated DR systems and trained technicians, we deliver flawless digital scans with detailed interpretation.Comprehensive Reporting

You receive a clear, actionable report—complete with annotated imagery, analytical insights, and recommendations.Trusted Standards & Compliance

Our services are built on accredited protocols, ensuring your results are accepted by insurers, surveyors, and regulatory bodies.

Frequently Asked Questions (FAQs)

1. What is Digital Radiography (DR)?

Digital Radiography is an advanced form of X-ray imaging that uses digital sensors instead of traditional film. It provides instant, high-resolution images that reveal internal flaws without damaging the component.

2. How is DR different from traditional radiography?

Unlike film-based radiography, DR offers:

Faster results (images available immediately)

Higher clarity and precision

No chemical processing or darkrooms

Easier storage, sharing, and traceability of results

3. What defects can DR detect?

DR is highly effective for finding:

Cracks and weld defects

Porosity and inclusions

Corrosion and wall thinning

Delamination in composites

Casting or manufacturing flaws

4. Is Digital Radiography safe?

Yes. Radiation exposure is much lower than traditional X-ray methods. Safety protocols are always followed to protect both personnel and the environment.

5. Can DR be used on boats and masts?

Absolutely. DR is ideal for marine applications such as mast inspections, rigging components, welds, and fittings. It reveals hidden damage that could compromise safety at sea.

6. Do I need to remove coatings or paint before inspection?

No. One of the advantages of DR is that it can often penetrate through coatings, insulation, or paint, allowing defects to be detected without stripping the surface.

7. Will DR damage my equipment?

No. DR is a non-destructive testing (NDT) method. It does not harm the component being inspected.

8. How long does a DR inspection take?

Most inspections can be completed quickly, depending on the size and complexity of the asset. In many cases, images are available within minutes of scanning.

9. Is DR accepted by insurers and surveyors?

Yes. Our inspections follow accredited standards and produce detailed, traceable reports that meet insurer and regulatory requirements.

10. How much does a Digital Radiography inspection cost?

Costs depend on the size, complexity, and access to the component. Contact Qualiss for a tailored quote.