Boat Mast Inspection & NDT Services

Ensure Safety, Performance & Reliability at Sea

A boat’s mast is one of the most critical components of its rigging system. Any hidden flaw – whether corrosion, cracking, or fatigue – can compromise safety and performance. At Qualiss, we provide specialised non-destructive testing (NDT) and inspection services for aluminium, carbon fibre, and composite masts to help sailors, boat owners, and commercial operators stay safe and confident on the water.

Why Mast Inspection Matters

Structural integrity: Masts endure enormous loads and stress. Even small cracks or defects can lead to catastrophic failure.

Hidden corrosion: Saltwater exposure and galvanic corrosion can weaken metal masts internally.

Safety assurance: A thorough inspection reduces the risk of rigging failures offshore or during races.

Cost savings: Early detection of defects helps avoid expensive repairs or replacements.

Applications of MPI in Industry

Qualiss MPI services are trusted across multiple sectors:

Marine & Offshore – hull weld inspections, masts, rig components, and corrosion detection.

Oil & Gas – pipeline welds, pressure vessels, storage tanks.

Construction & Infrastructure – steel beams, bridges, and structural components.

Energy & Power – turbine shafts, boiler tubes, and plant equipment.

Manufacturing & Fabrication – castings, forgings, assembly welds.

Real-world impact: MPI helps prevent costly downtime, equipment failure, and safety hazards by identifying flaws before they escalate.

Our Inspection & NDT Capabilities

We use advanced inspection and testing methods tailored to boat masts, ensuring accuracy without damage to the structure:

Visual Inspection (VT): First-line assessment to detect visible cracks, wear, and mechanical damage.

Ultrasonic Testing (UT): Identifies internal flaws, thickness loss, and delaminations in metal or composite masts.

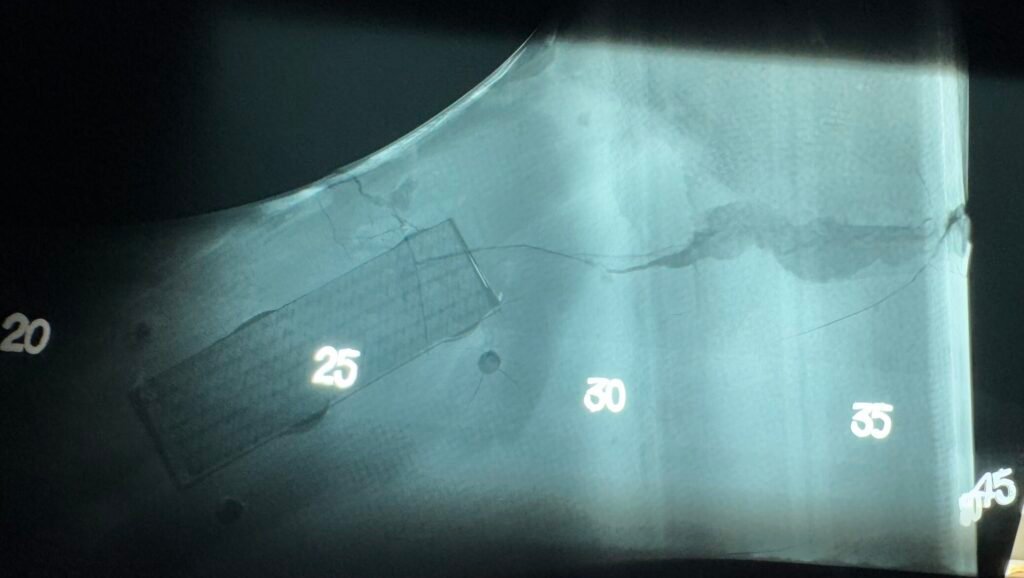

Digital Radiography (DR): Provides detailed imaging for welds, fittings, and hidden internal damage.

Magnetic Particle Testing (MT): Detects surface and near-surface cracks in ferromagnetic components (mast fittings, welds, brackets).

Dye Penetrant Testing (PT): Locates fine cracks in non-porous materials such as stainless-steel mast fittings.

IRIS & Guided Wave (where applicable): Advanced options for detecting internal wall loss and long-range flaws.

Typical Mast Defects We Detect

✔ Cracks in welds and joints

✔ Delamination in carbon fibre masts

✔ Corrosion under paint or coatings

✔ Fatigue damage at fittings and spreaders

✔ Manufacturing defects or improper repairs

Who We Work With

Yacht owners & operators

Competitive sailing teams

Shipyards & boat builders

Commercial & charter fleets

Insurance & survey companies

Frequently Asked Questions (FAQs)

1. Why do I need to inspect my boat mast?

Boat masts experience constant stress from sailing loads, wind, and rigging tension. Even small cracks or corrosion can lead to sudden failure. Regular inspection helps ensure safety, performance, and compliance with insurance or survey requirements.

2. How often should a mast be inspected?

For recreational vessels, we recommend a mast inspection every 2–3 years. For racing yachts, charter boats, or commercial operators, inspections should be carried out annually or before major events.

3. What types of masts can you inspect?

We inspect aluminium, carbon fibre, and composite masts of all sizes. Our non-destructive testing (NDT) methods can also be applied to fittings, welds, and spreaders.

4. Will NDT damage my mast?

No. Non-destructive testing (NDT) is designed to detect flaws without causing any damage. Techniques like ultrasonic testing and digital radiography allow us to see inside the mast structure safely.

5. What defects can you find in a mast?

We commonly detect:

Cracks in welds and fittings

Corrosion under paint or coatings

Delamination in composite masts

Fatigue damage from racing loads

Defects from previous repairs

6. Do you provide inspection reports?

Yes. Every inspection comes with a comprehensive report, including images (where applicable), defect descriptions, and recommendations for repair or monitoring.

7. Can mast inspections be done while the mast is stepped (still on the boat)?

In most cases, yes. Many NDT techniques can be performed with the mast in place, although certain inspections may require the mast to be unstepped for full access.

8. Are your mast inspections recognised by insurers and surveyors?

Yes. We follow accredited procedures and provide reports suitable for insurance claims, compliance checks, and marine surveys.