Check Out Some of Our Previous Projects

AS 3788:2024 — In-Service Inspection of Pressure Equipment

Stay compliant in Queensland with this practical guide to AS 3788:2024. Learn how to plan inspections, set risk-based intervals, choose the right NDT, prepare for audits, and manage PSVs and piping.

The Ultimate Guide to 10-Year Crane (Major) Inspections in Australia under AS 2550.1

During a 10 Yearly Boom Inspection, Qualiss removed the boom from a truck crane for comprehensive Magnetic Particle and Visual Testing.

10 Yearly Boom Inspection – Magnetic Particle and Visual Testing

During a 10 Yearly Boom Inspection, Qualiss removed the boom from a truck crane for comprehensive Magnetic Particle and Visual Testing.

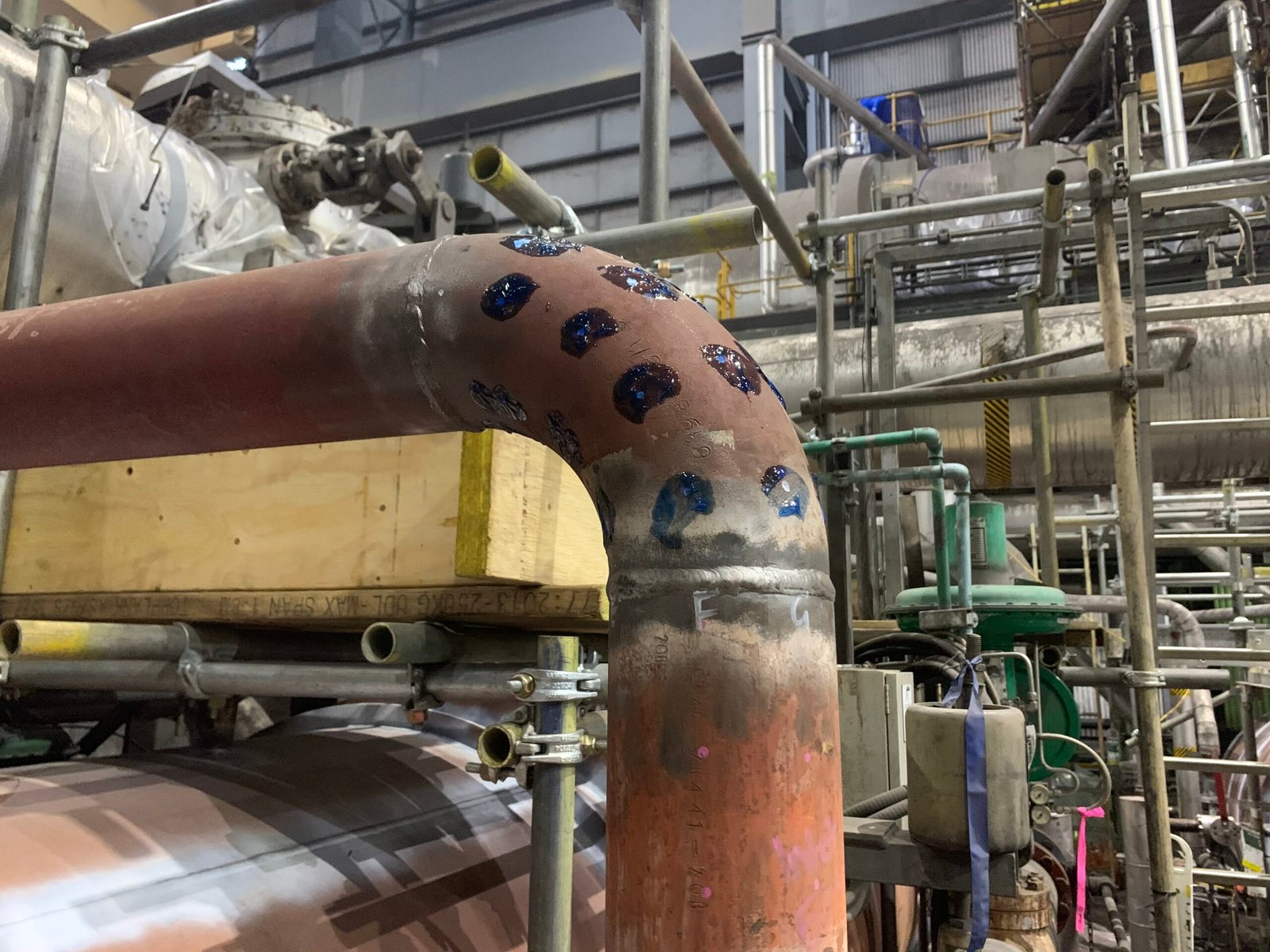

Crack Found in Condensate Return Line Flange

During a routine visual inspection at a paper mill, Qualiss identified a crack in a flange on the condensate return line. The indication aligned with corrosion and cyclic thermal stresses common to condensate systems.

Tube Bundle Fabrication and Testing – From Weld to Hydrotest

A precision-engineered tube bundle fabricated and tested by Qualiss underwent full NDT including visual weld examination, dye penetrant inspection, and hydrostatic pressure testing to verify integrity before commissioning.

Crane Inspection NDT – Cracks Found in Palfinger Cylinder

Cracks were found in a Palfinger crane hydraulic cylinder during an NDT inspection and confirmed with MPI — a clear reminder why regular crane inspection NDT is vital.

10-Yearly Crane Testing in Australia: Cracks Found

Reduce downtime and prevent failures. Our 10-yearly crane inspections combine Eddy Current and Magnetic Particle Testing to ensure safe, certified operations.

Closed Grid UT Surveys in Power Stations

Closed Grid Ultrasonic Testing delivers precise thickness mapping across boilers, pipes, and vessels — giving power stations early detection of corrosion and reliable data for maintenance planning

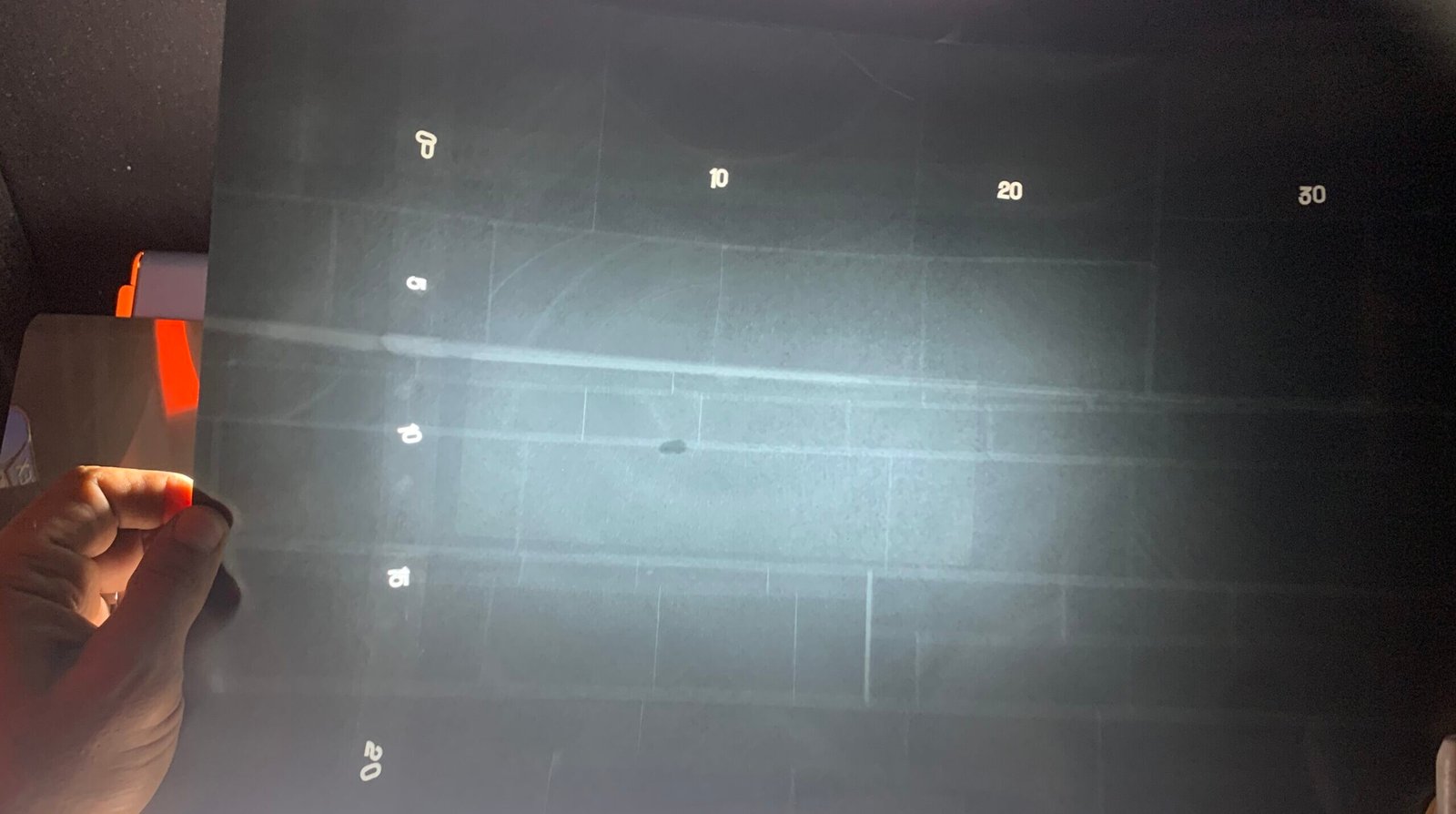

Boat Hull Radiography: Detect Hidden Damage in Your Vessel

Lightning may leave a mast looking intact, but internal voids can compromise its strength. Our radiography inspections uncover hidden defects before they become a danger

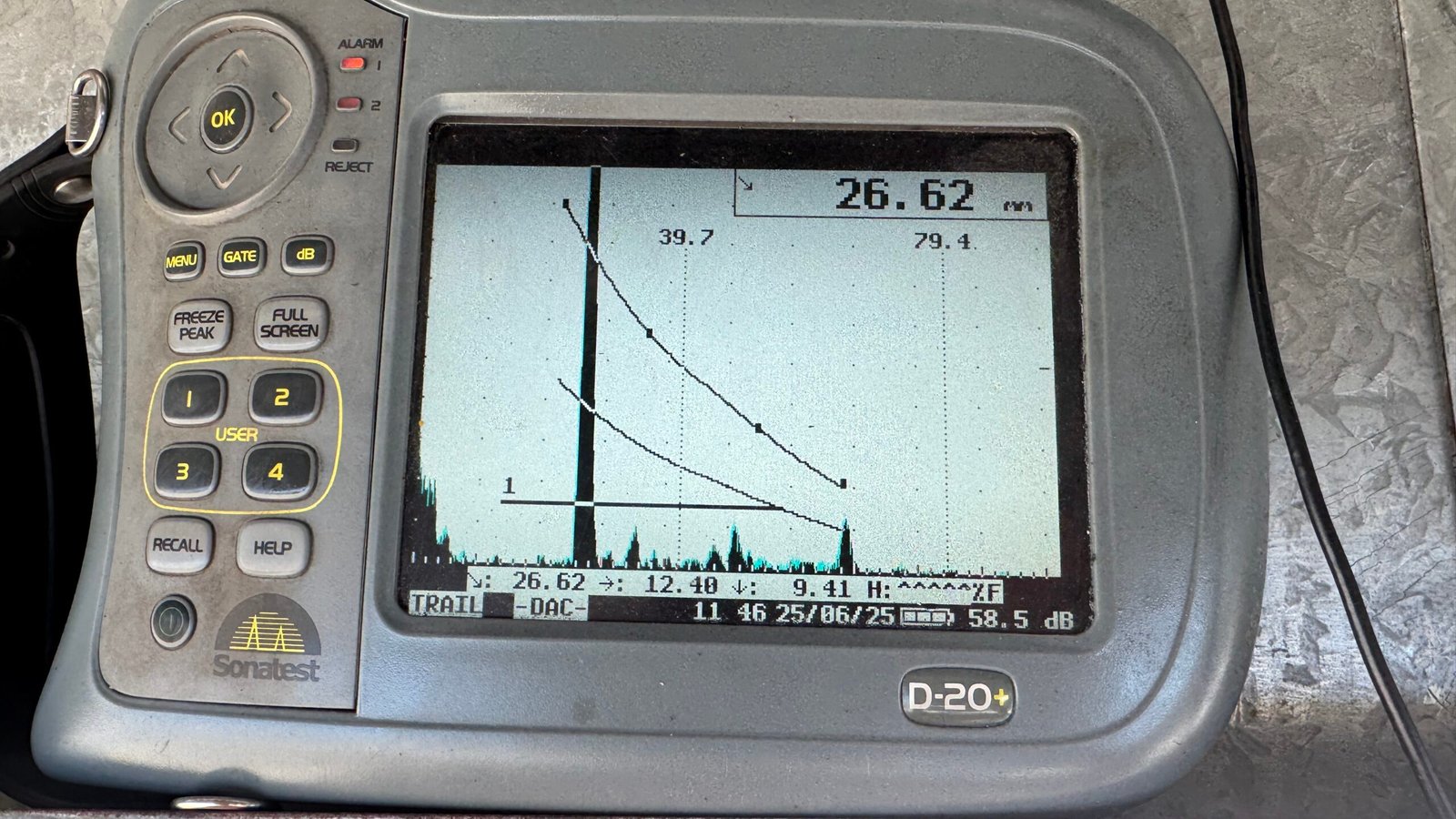

Detecting Cracks in Welds with Ultrasonic Testing

Ultrasonic Testing detects hidden weld cracks before they become a safety risk, keeping your assets secure and compliant.

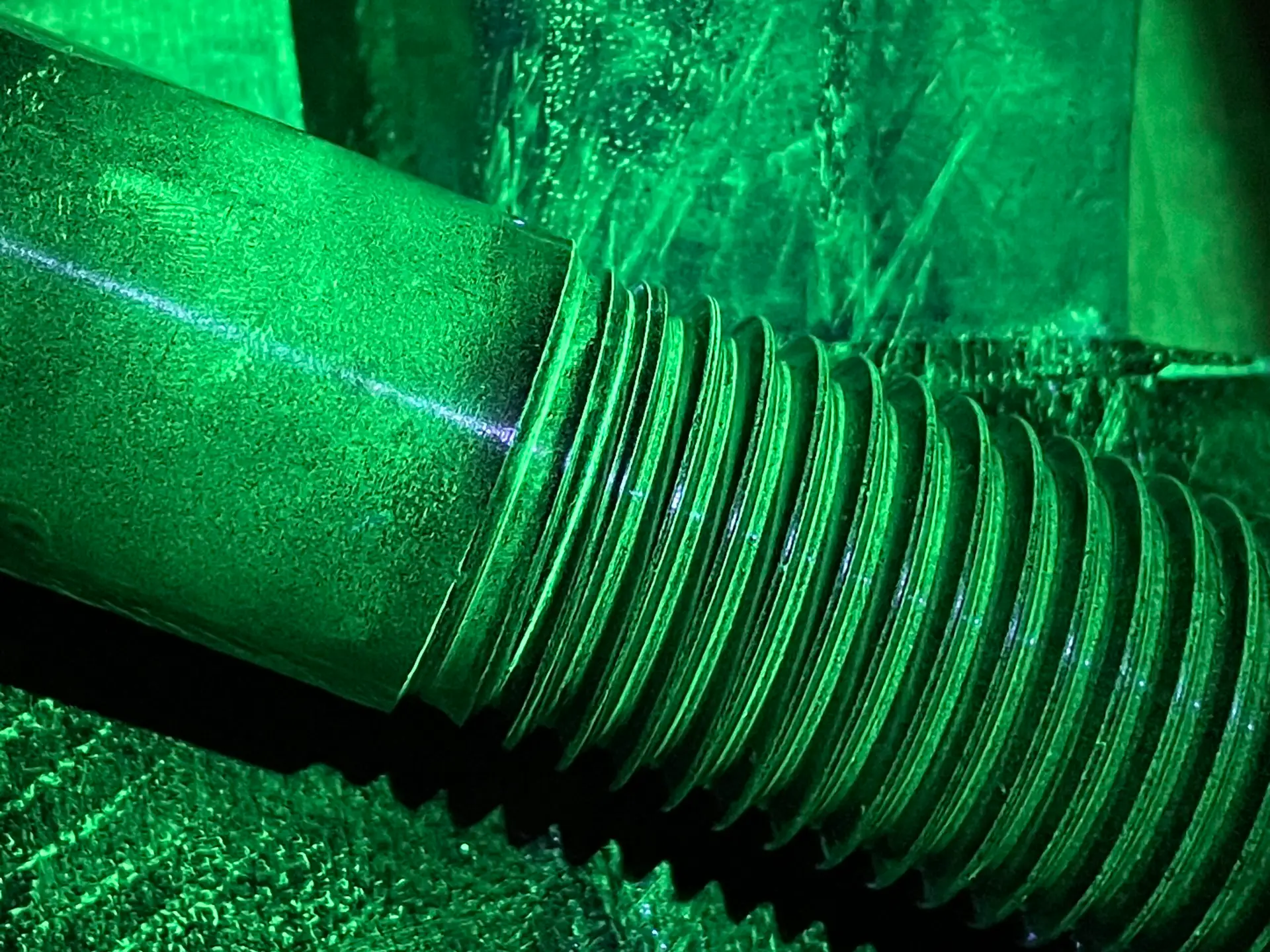

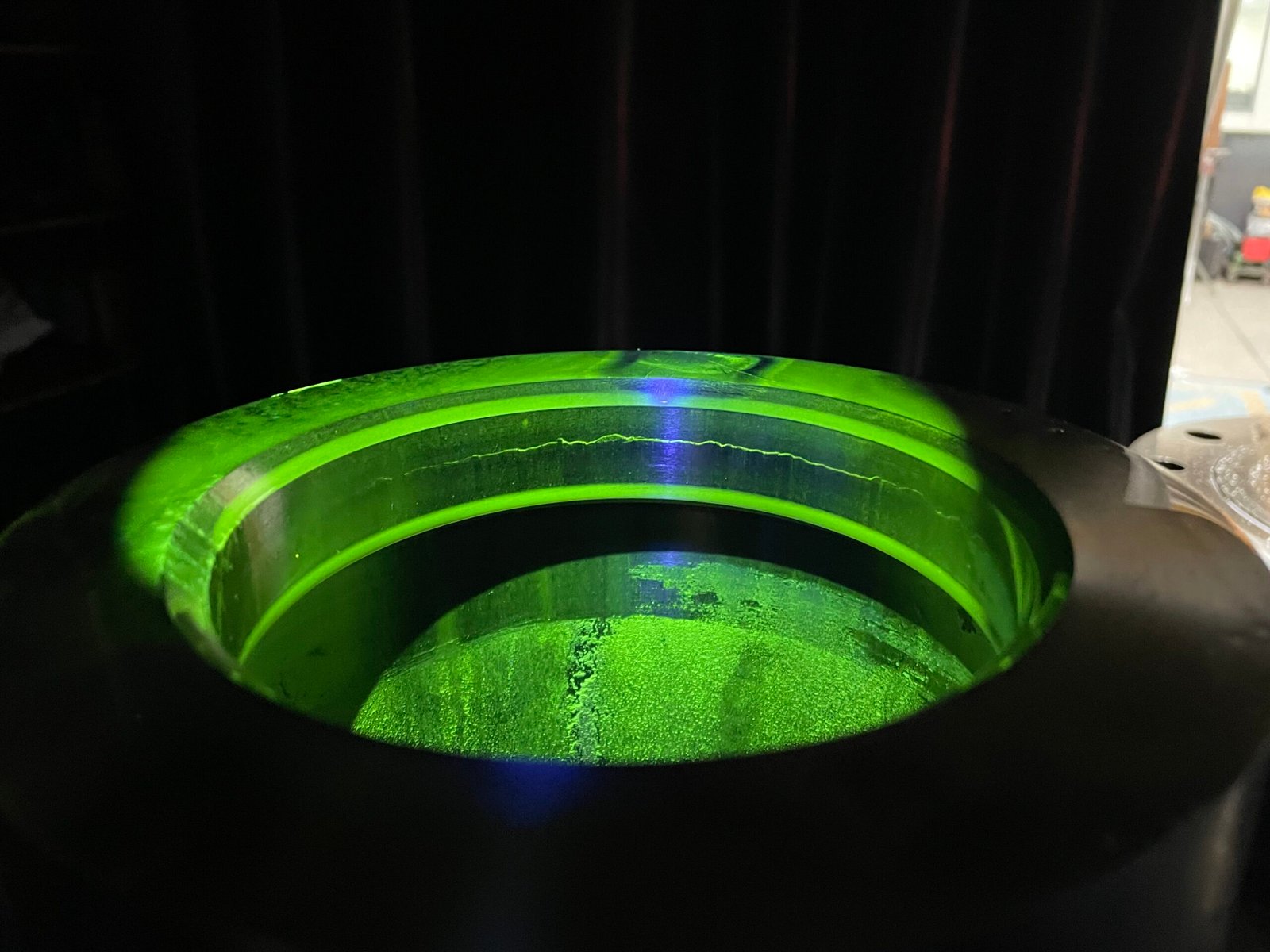

Illuminating Flaws: Using Fluorescent MPI to Inspect Hydro Turbine Hold-Down Bolts

When inspecting Stellite welds on mild steel, Magnetic Particle Inspection often shows false crack-like indications due to grain structure differences.

Dye Penetrant Inspection Tank Manway – Ensure Safe Operation

Dye Penetrant Inspection (DPI) is one of the most effective ways to detect surface cracks and weld defects on tank manways — even after installation. By revealing flaws that could compromise safety and reliability, DPI provides a fast, non-destructive, and cost-effective solution for ensuring tanks remain secure and compliant.

Stellite Welding: The False Positive Crack Indication

When inspecting Stellite welds on mild steel, Magnetic Particle Inspection often shows false crack-like indications due to grain structure differences.