Your mast takes the load every time you sail. Hidden cracks, corrosion, or fatigue can lead to costly failures at sea. Our expert NDT mast inspections detect issues early, ensuring safety, performance, and peace of mind for every voyage.

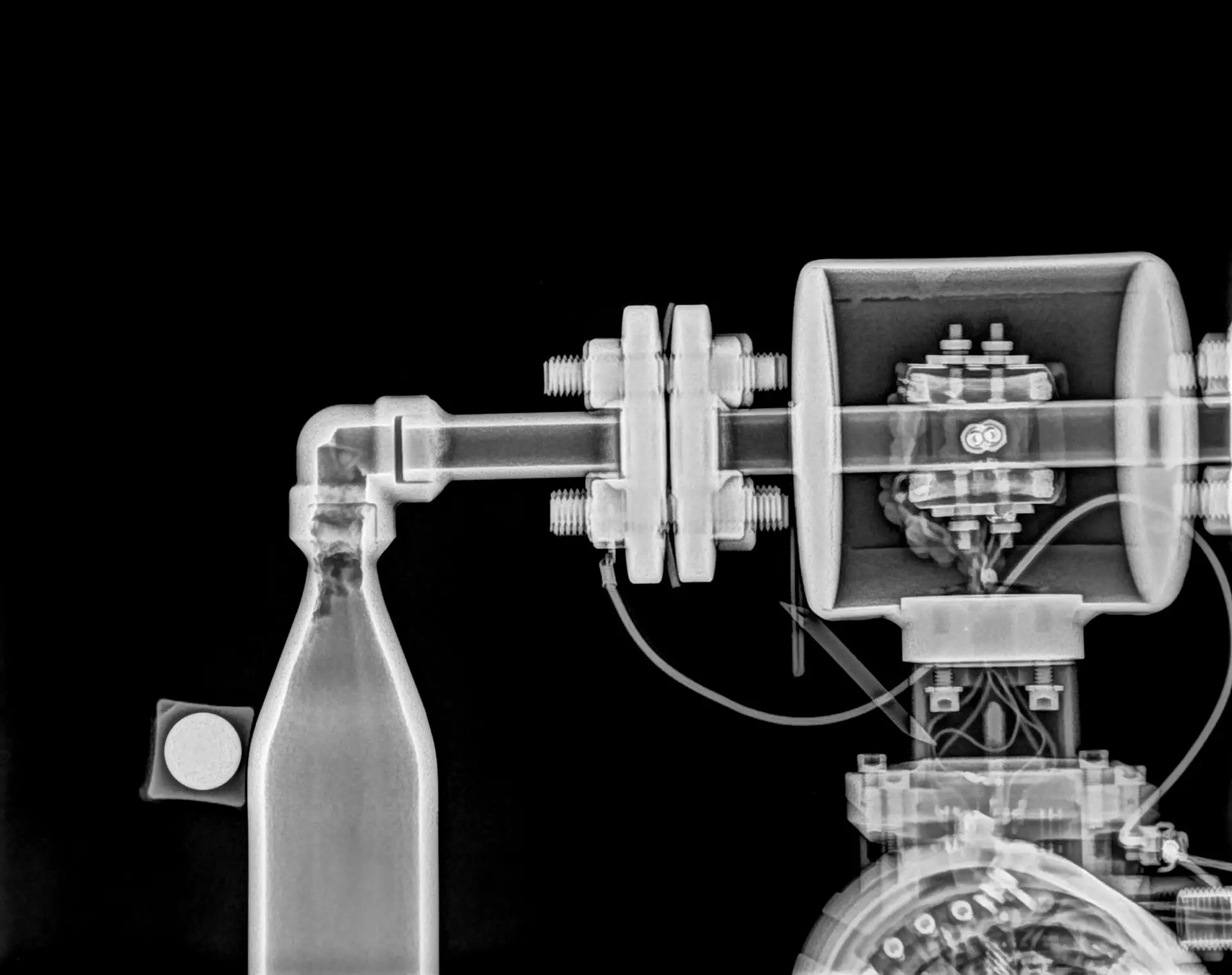

Digital Radiography (DR) is a cutting-edge non-destructive testing (NDT) method that uses advanced digital imaging technology to inspect materials and components for internal flaws without causing damage.

Accurately detect corrosion, wall loss, and pitting inside heat exchanger and boiler tubes with Internal Rotary Inspection System (IRIS) ultrasonic testing. A precise, reliable method for extending asset life and ensuring compliance.

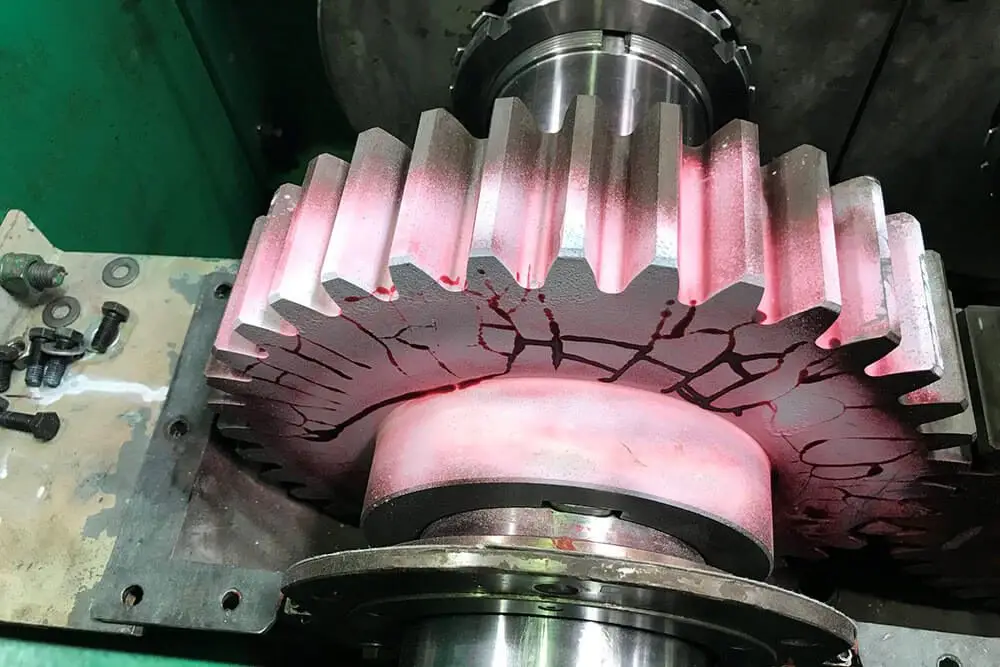

Uncover hidden cracks before they cause costly failures. Our Magnetic Particle Inspection (MPI) quickly and reliably detects surface and near-surface defects in ferromagnetic materials, keeping your assets safe, compliant, and performing at their best

Reveal the unseen with Dye Penetrant Inspection — a fast, reliable, and cost-effective method to detect even the smallest surface flaws. From hairline cracks to porosity, our advanced testing ensures your assets remain safe, compliant, and performing at their best.

Go beyond the surface with Ultrasonic Testing. Our high frequency sound waves uncover hidden, internal flaws and precisely measure material thickness even on in-service assets delivering integrity, compliance, and peace of mind with zero downtime