Early Crack Detection in Geothermal Turbine Bolts Using Fluorescent MPI

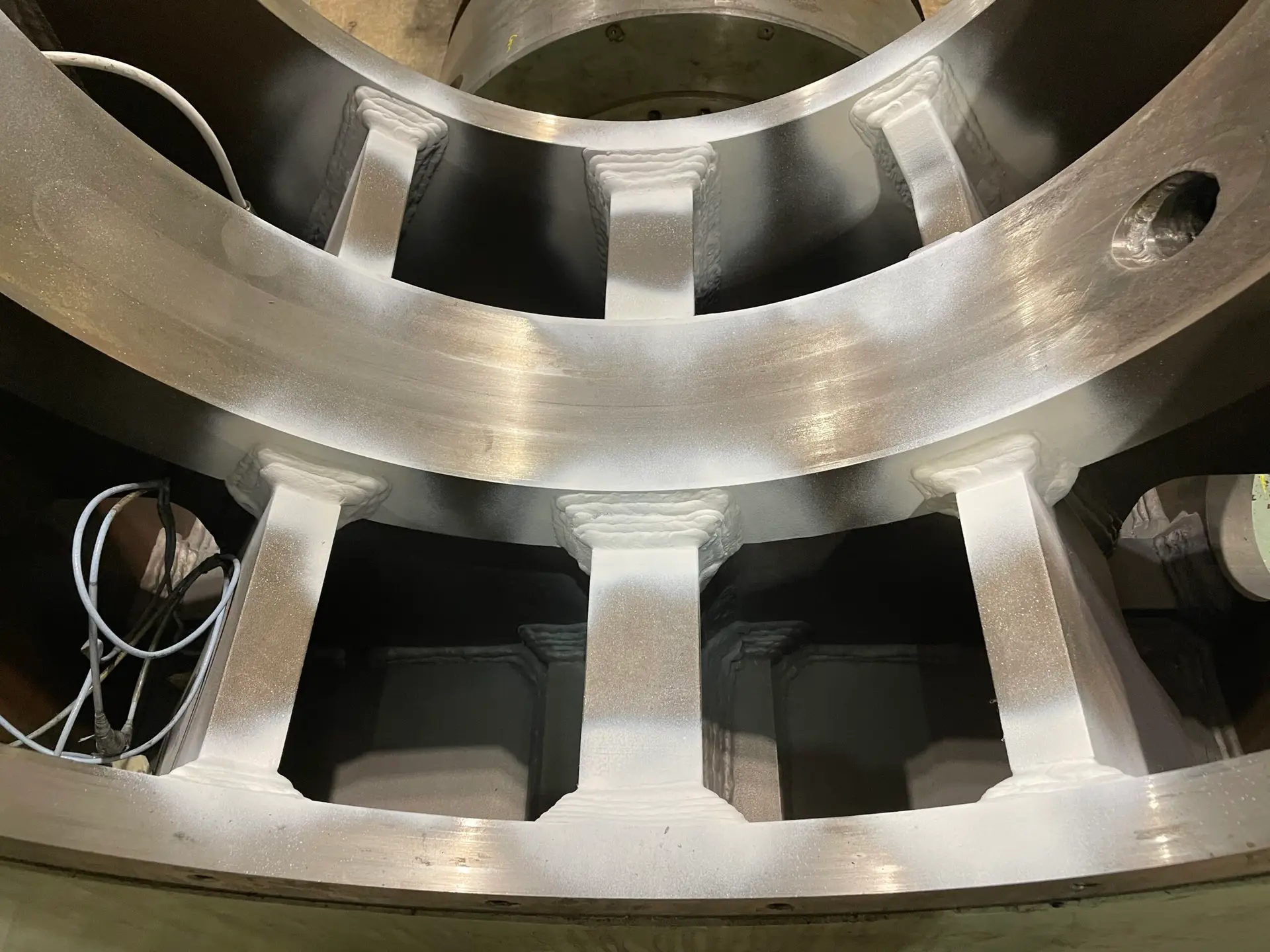

Geothermal turbines operate under extreme stress, with high-pressure driving rotation continuously. The integrity of hold-down bolts is critical — even a small crack can compromise performance or lead to catastrophic failure. That’s why non-destructive testing (NDT) is essential for turbine maintenance.

Why Hold-Down Bolts Are Critical

These bolts endure high tensile loads, vibration, and thermal cycling. Over time, micro-cracks can develop in the threads or shank, often invisible to the naked eye. Missing these defects can result in:

Structural failure

Unexpected downtime

Safety hazards for operators and infrastructure

Why Fluorescent Magnetic Particle Inspection (MPI) Works

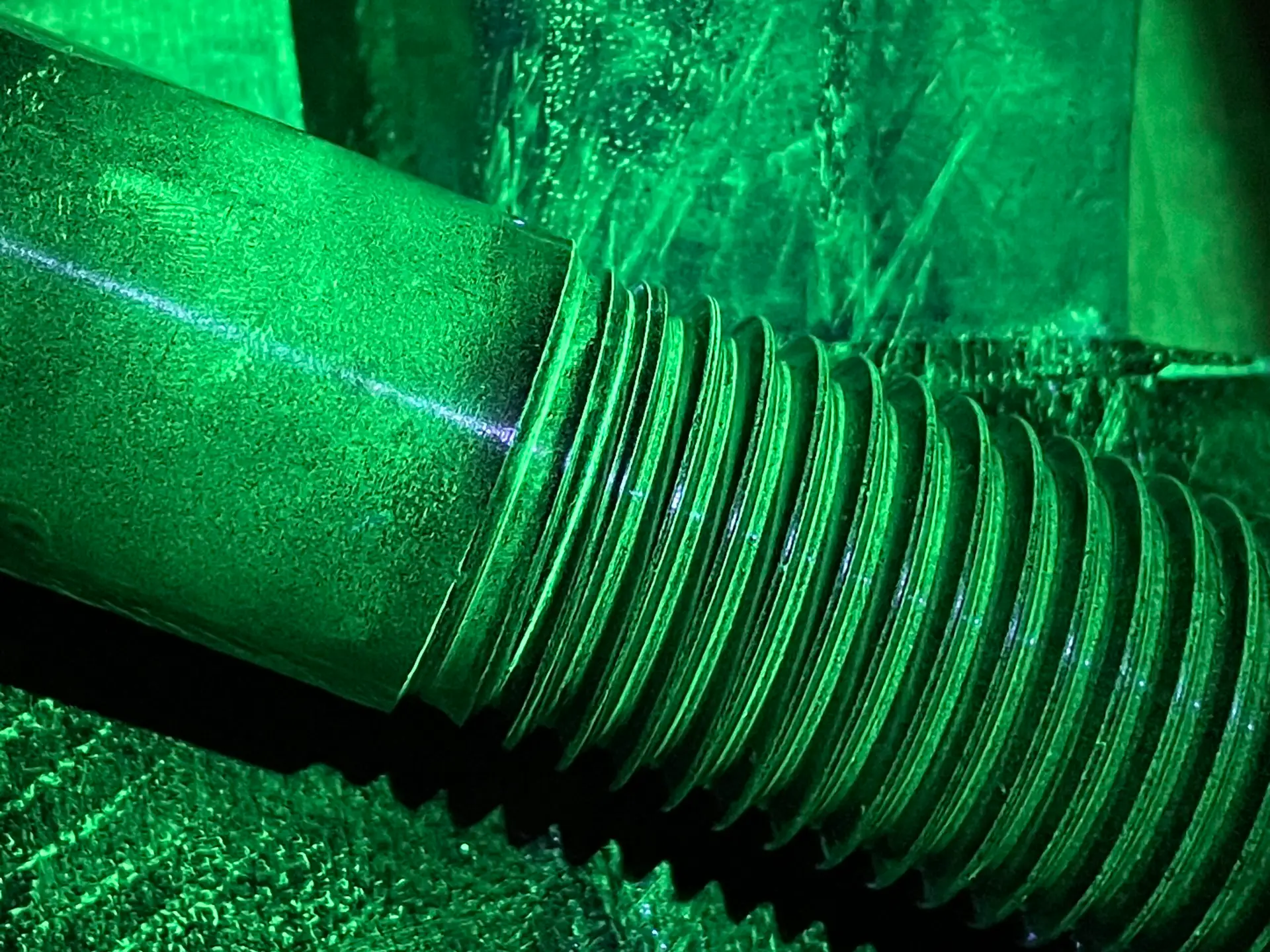

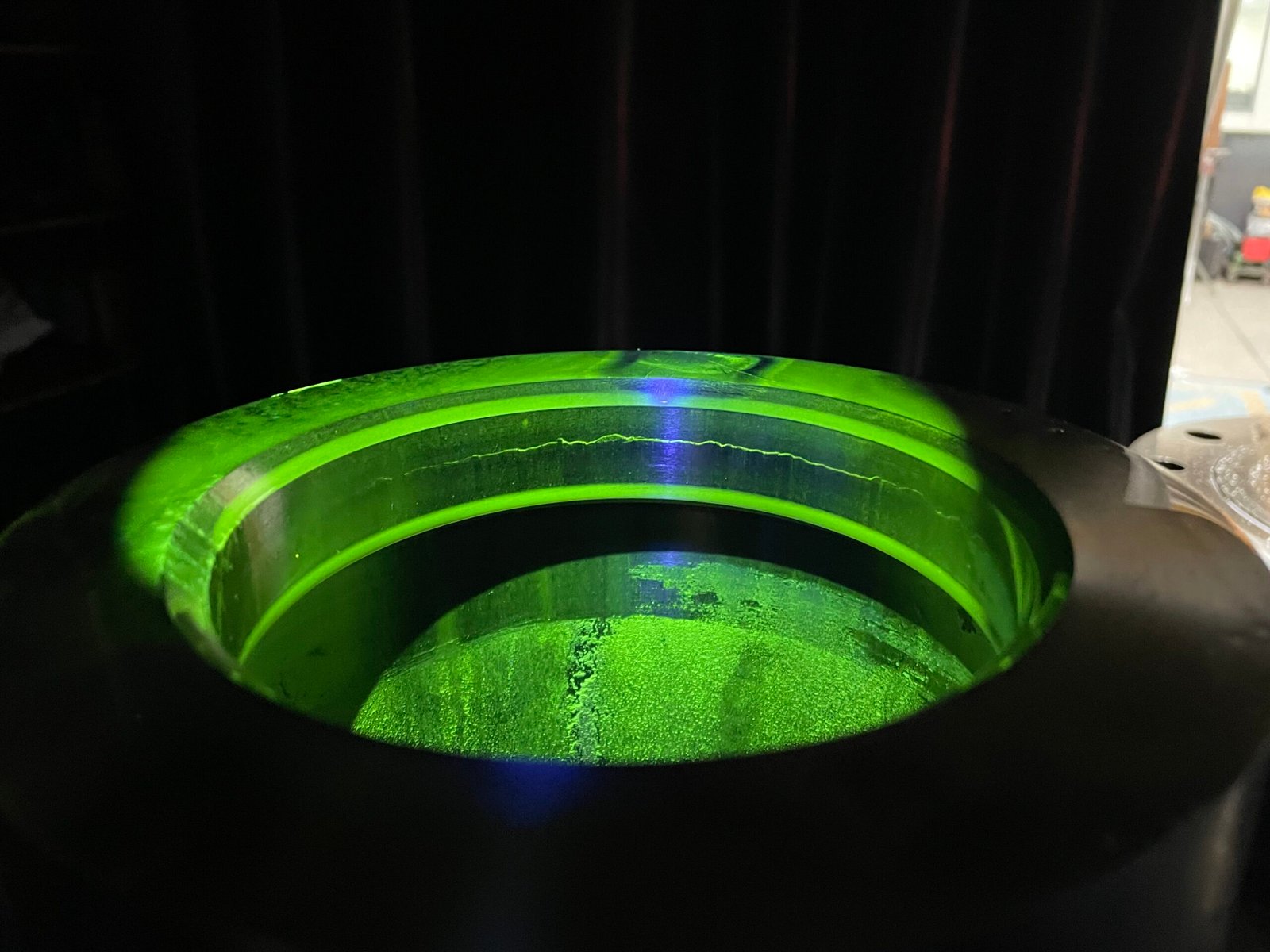

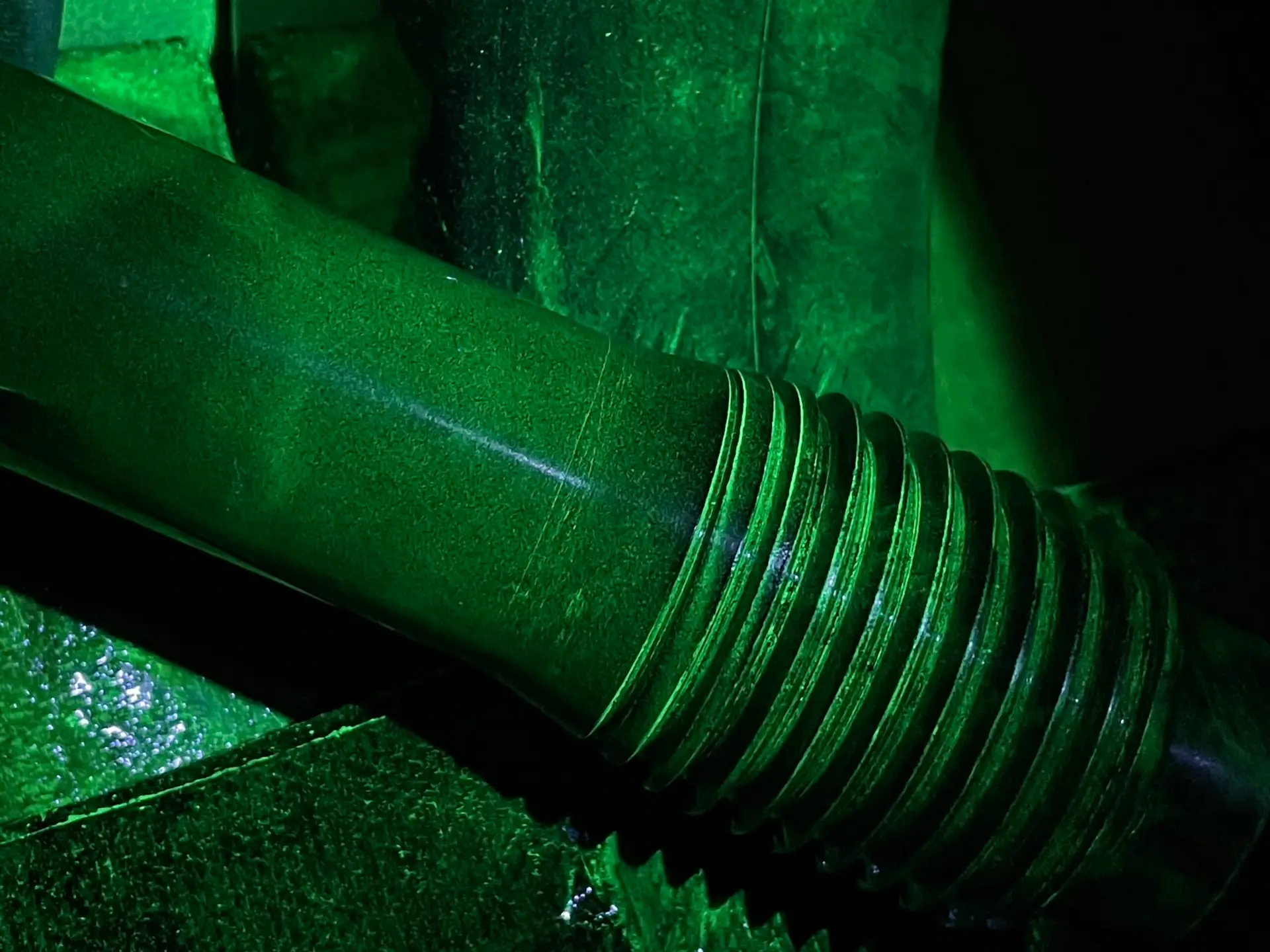

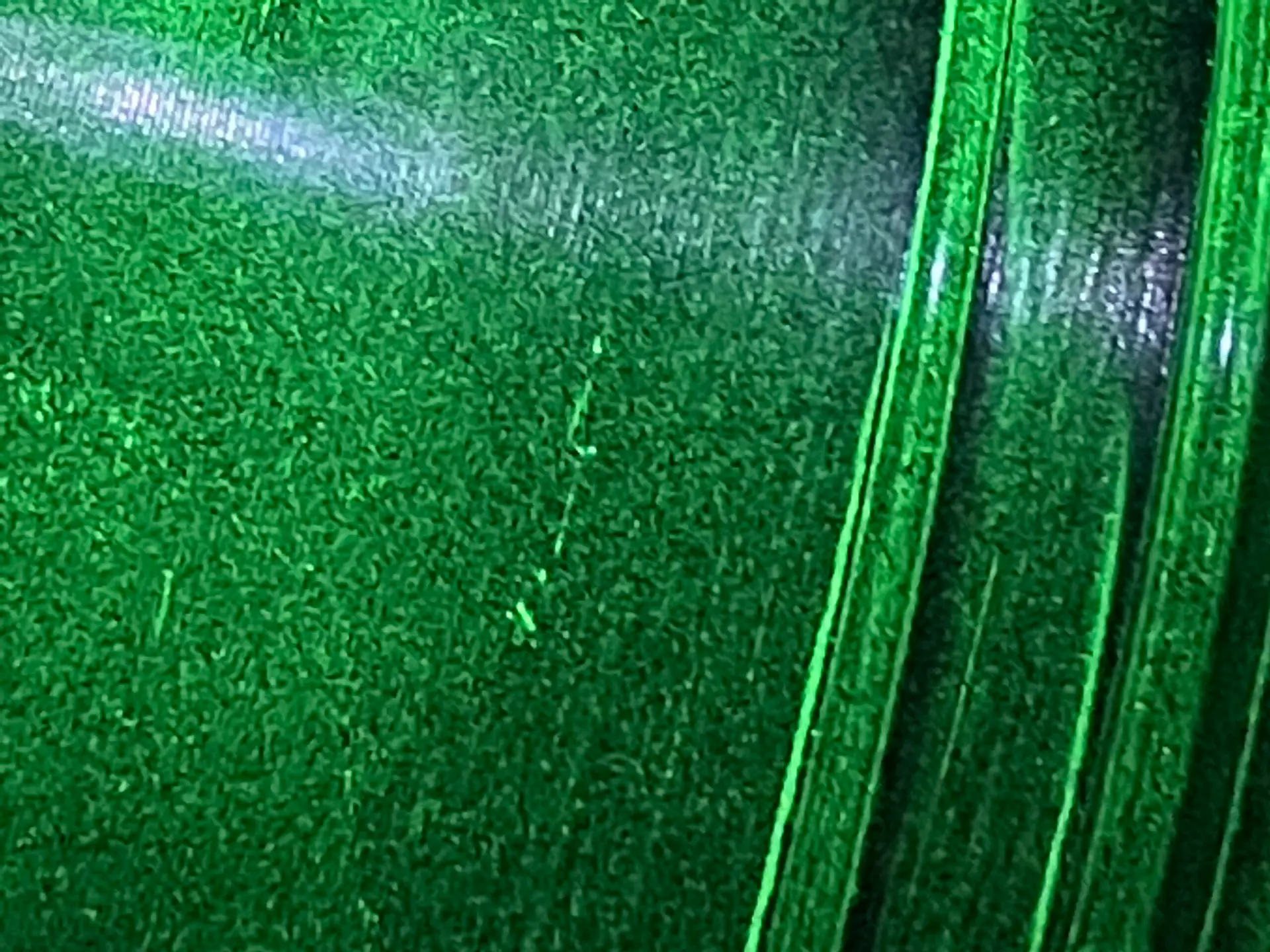

Fluorescent MPI is a highly sensitive NDT method that highlights even hairline cracks and surface discontinuities. Using UV light, fluorescent particles glow against the metal surface, making flaws immediately visible.

Benefits for Geothermal Turbine Bolts:

Detects extremely small cracks — often less than 0.1 mm

Rapid inspection — entire bolt assemblies can be checked in minutes

Clear visualization — glowing indications make defect recognition straightforward

Non-destructive — preserves bolt integrity while identifying critical flaws

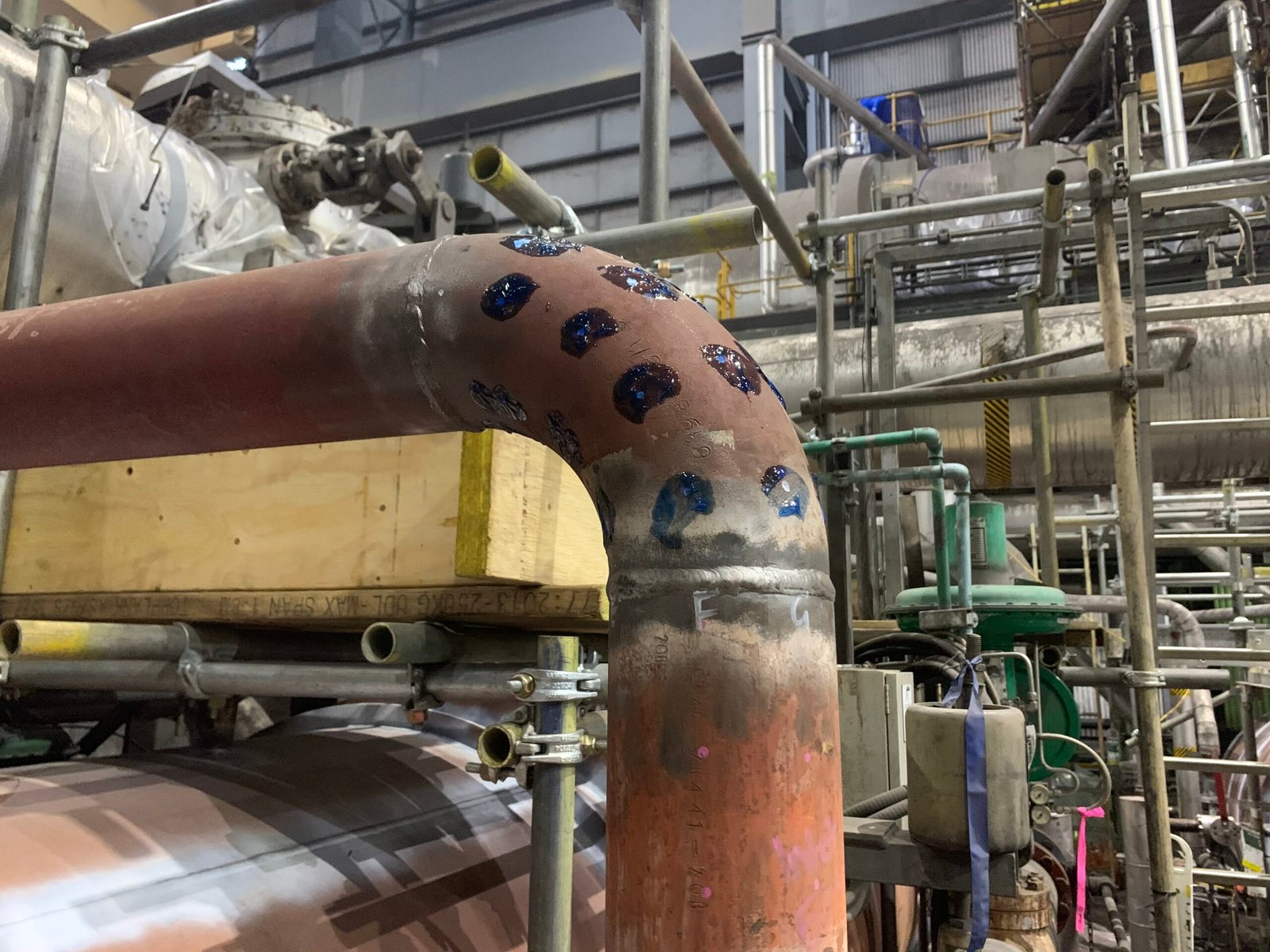

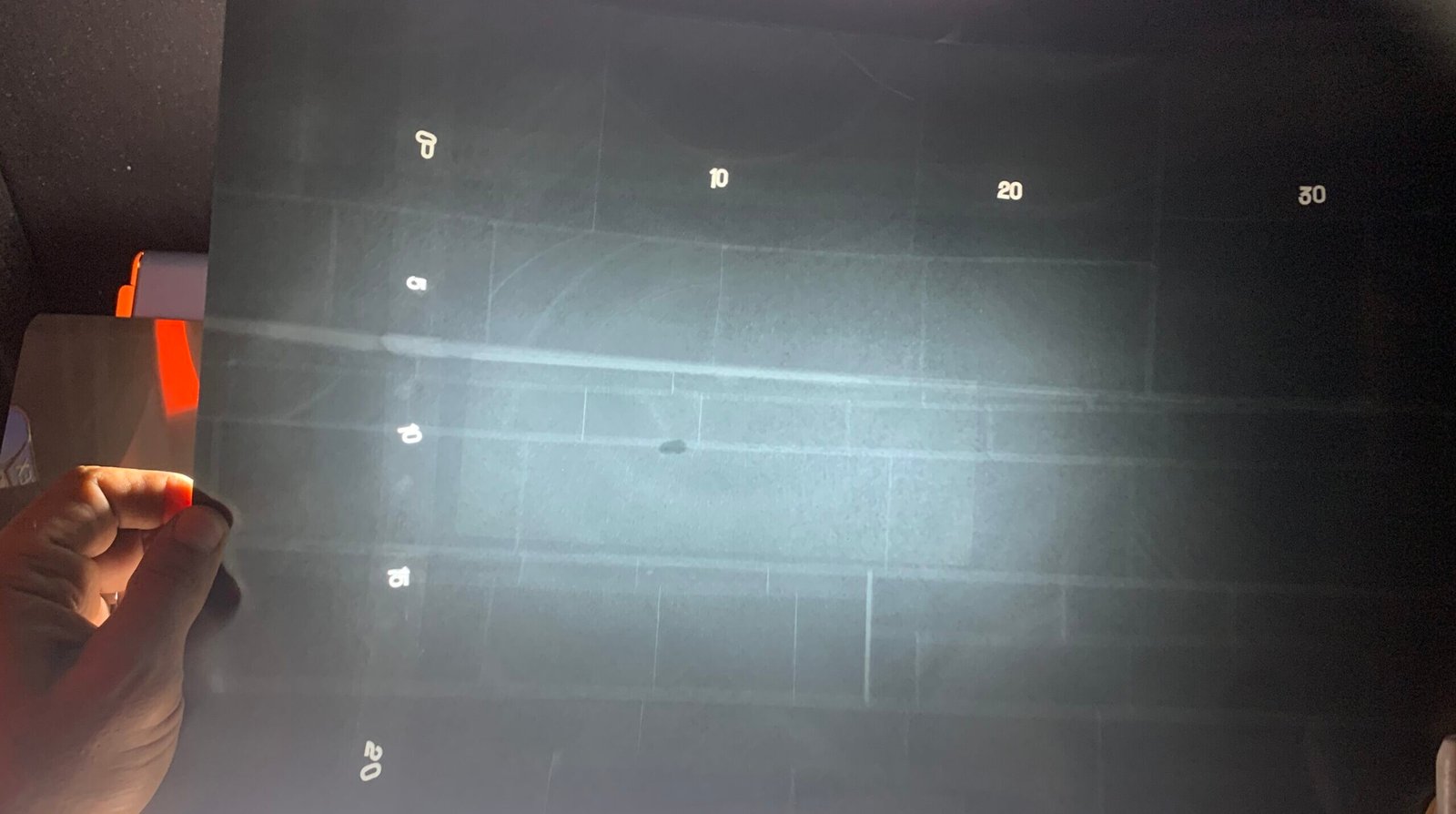

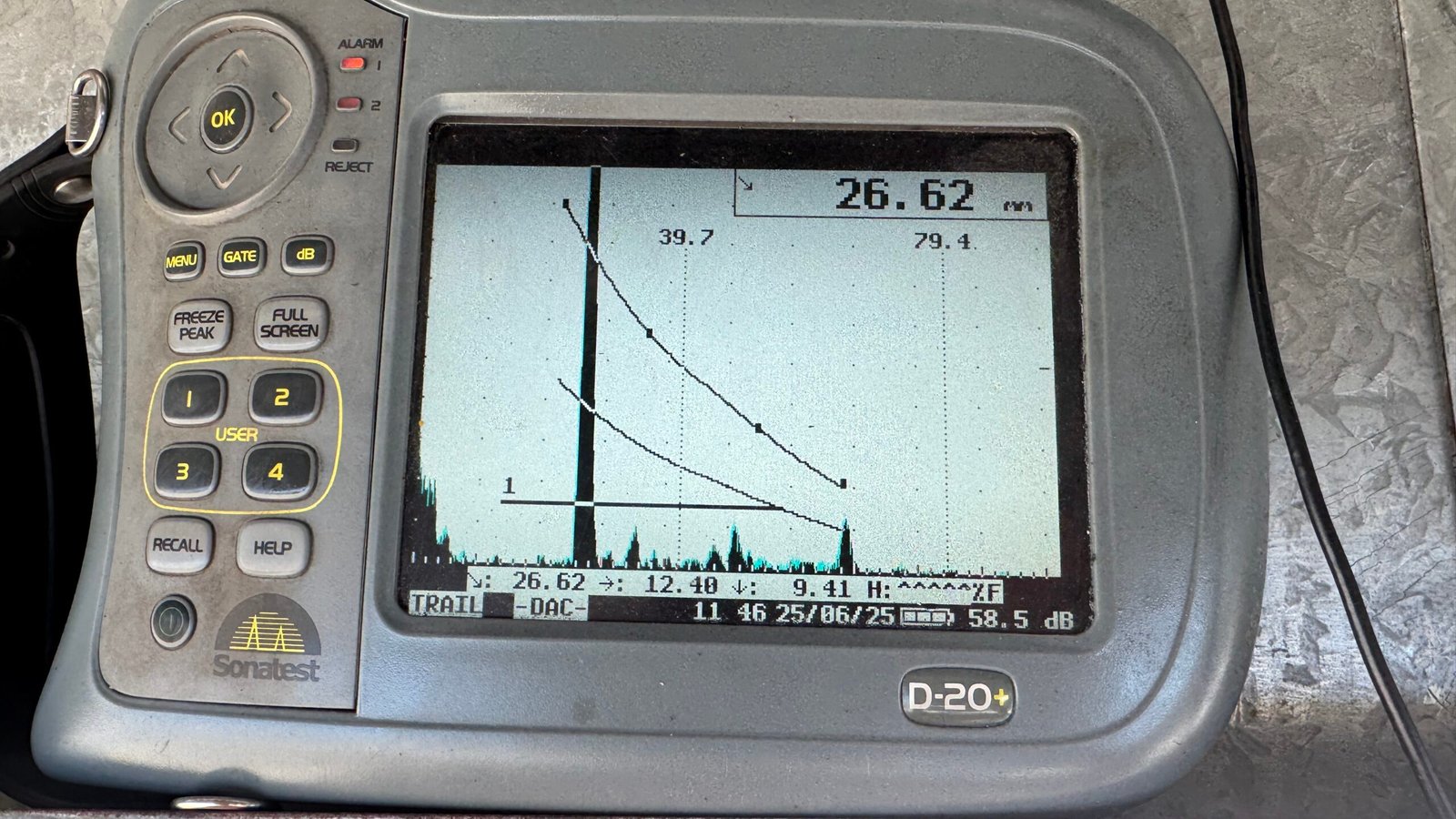

Real-World Findings

During recent inspections, our team found previously undetected micro-cracks in hold-down bolts using fluorescent MPI. Early detection allowed the maintenance team to replace compromised bolts before failure, preventing costly downtime and maintaining safe, reliable turbine operation.

“MPI on Stellite welds may produce false indications. Penetrant Testing provides accurate confirmation of surface cracks, porosity, or lack of fusion”

Best Practices for Inspecting Geothermal Turbine Bolts

Clean the surface thoroughly — remove oil, scale, or residue.

Magnetize the bolt — using a yoke, coil, or prod method.

Apply fluorescent particles — wet or dry method depending on conditions.

Inspect under UV light — look for glowing indications of cracks.

Document findings — maintain records for maintenance planning and regulatory compliance.

Why Expertise Matters

Fluorescent MPI is highly effective, but interpreting indications requires experience and skill. False positives can arise from surface conditions, threading, or bolt geometry. At Qualiss, our NATA-accredited inspectors combine precise technique with expert analysis to ensure every bolt is evaluated accurately.

Conclusion

Geothermal turbines are critical infrastructure, and hold-down bolts are their unsung heroes. Using fluorescent MPI, cracks can be identified early, preventing catastrophic failure and extending component life.

Protect your turbines, prevent downtime, and ensure safety — trust expert NDT inspections to see what others can’t.