Introduction

When it comes to the safety and reliability of tanks in industrial and marine environments, manways are critical access points. Over time, these areas can become prone to cracking, porosity, or weld defects due to operational stresses, pressure cycles, and environmental exposure. That’s why Dye Penetrant Inspection (DPI) remains one of the most effective, efficient, and non-destructive testing (NDT) methods for detecting surface-breaking flaws in stainless steel manway welds and fittings even after installation.

Why Tank Manways Require Special Attention

Manways are subject to constant use and maintenance activity. They also experience:

Stress concentrations around welds and attachment points

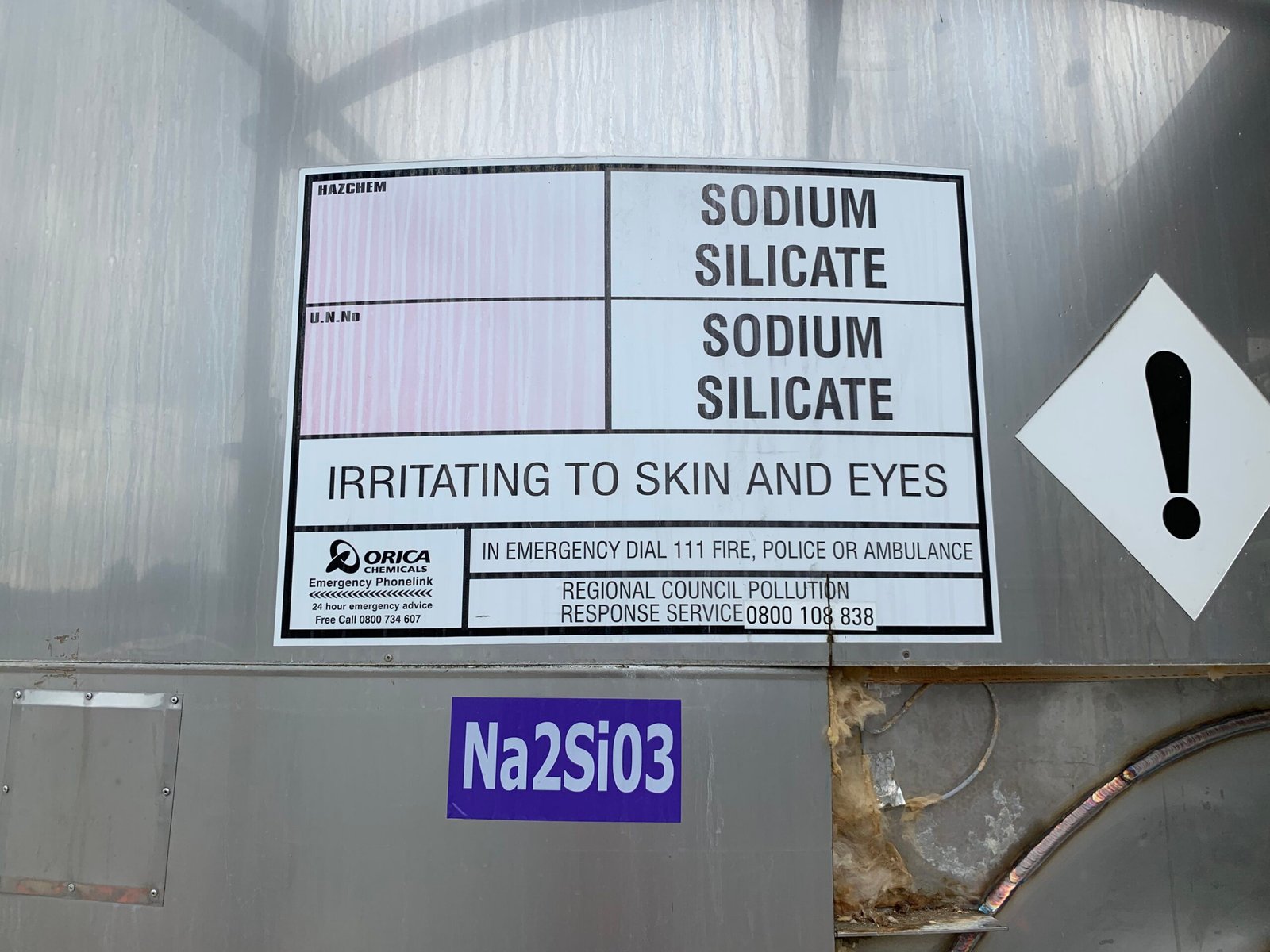

Corrosive environments, especially in marine or chemical storage applications

Thermal cycling that may initiate fine surface cracks

Even small imperfections in these areas can quickly compromise tank integrity, leading to costly leaks or downtime.

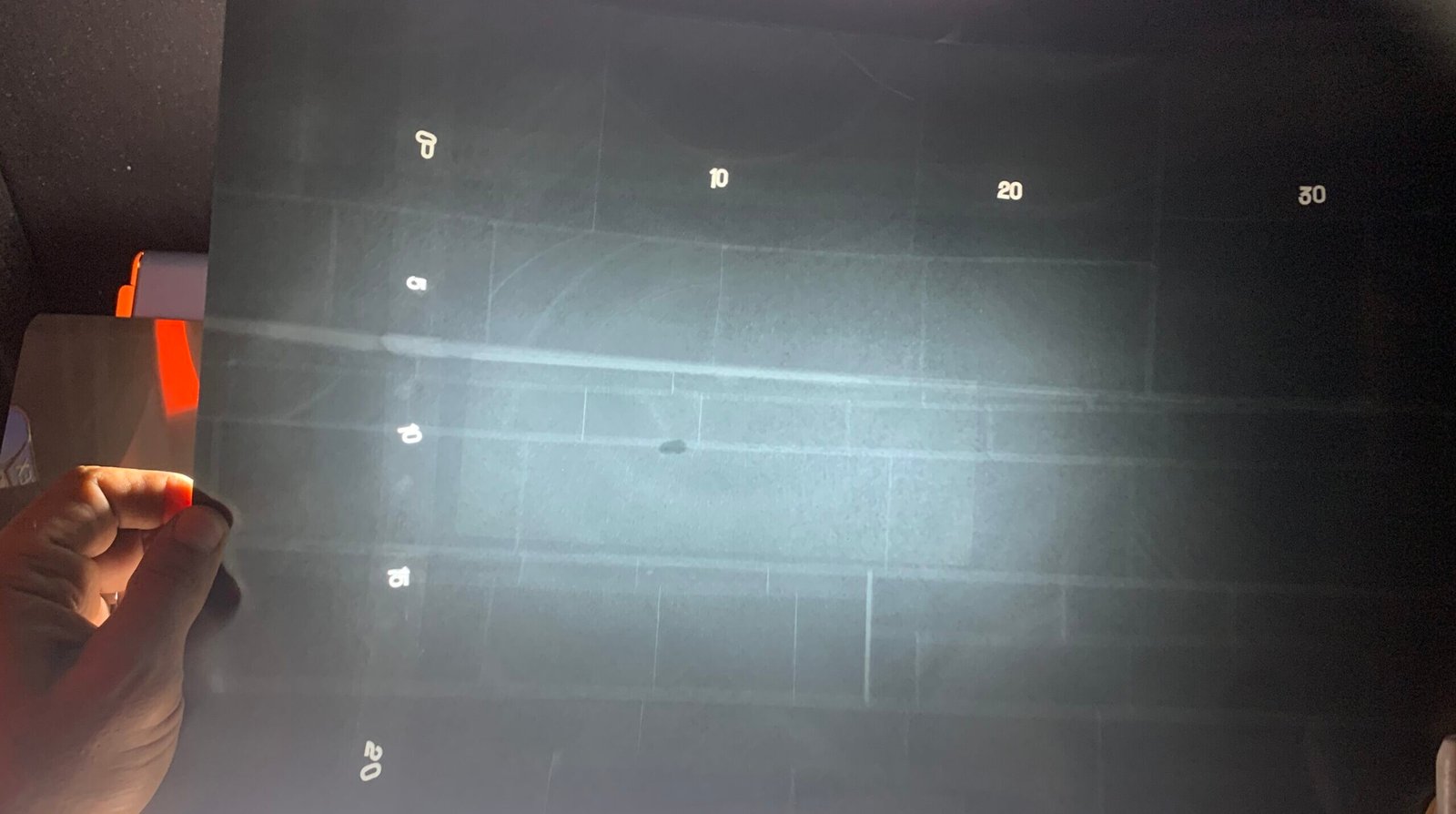

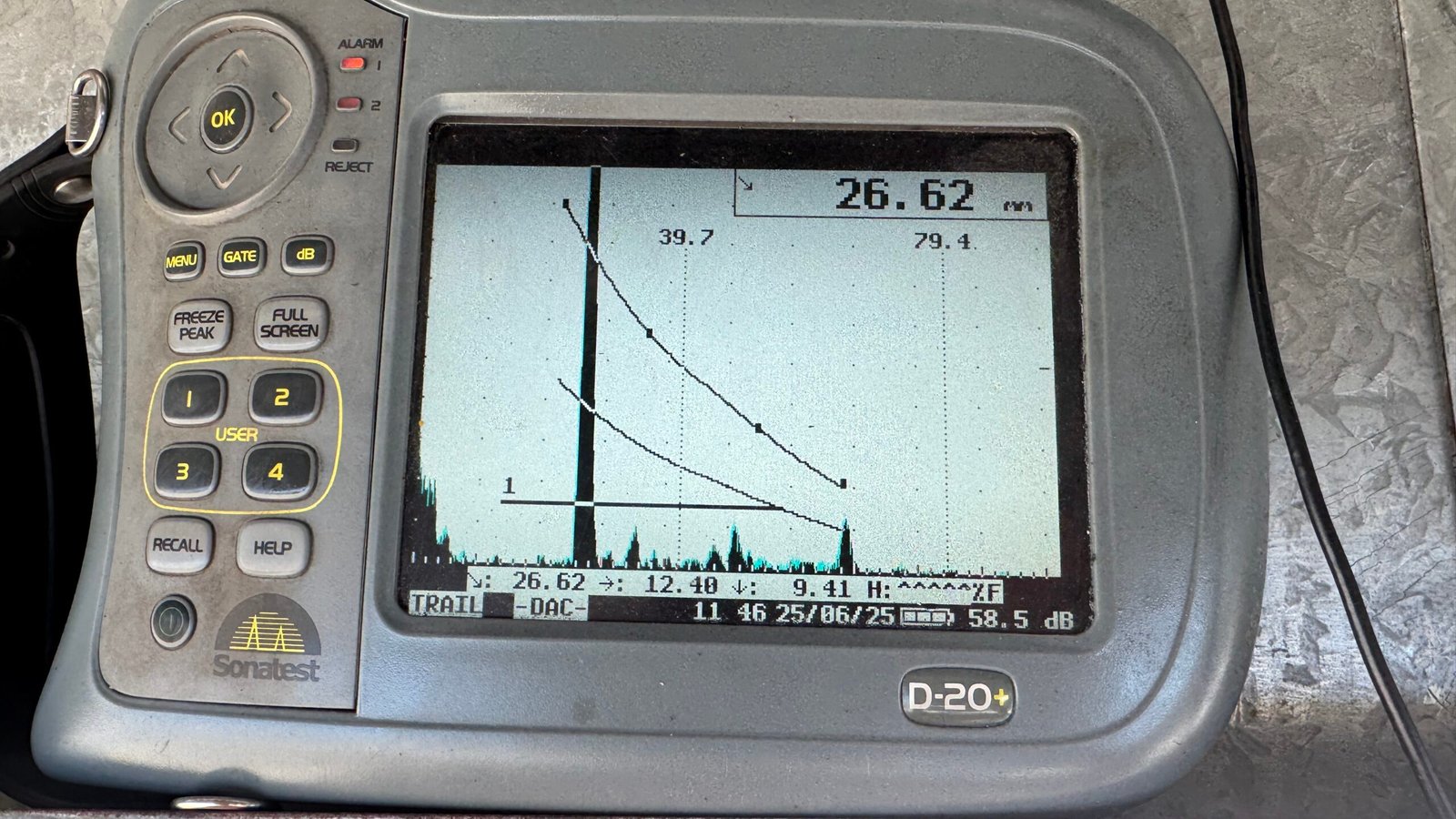

How Dye Penetrant Inspection Works on Installed Manways

One of the major advantages of DPI is that it can be performed on installed components without removing the manway. The process involves:

Surface Cleaning – Removing dirt, paint, and scale to expose the bare metal.

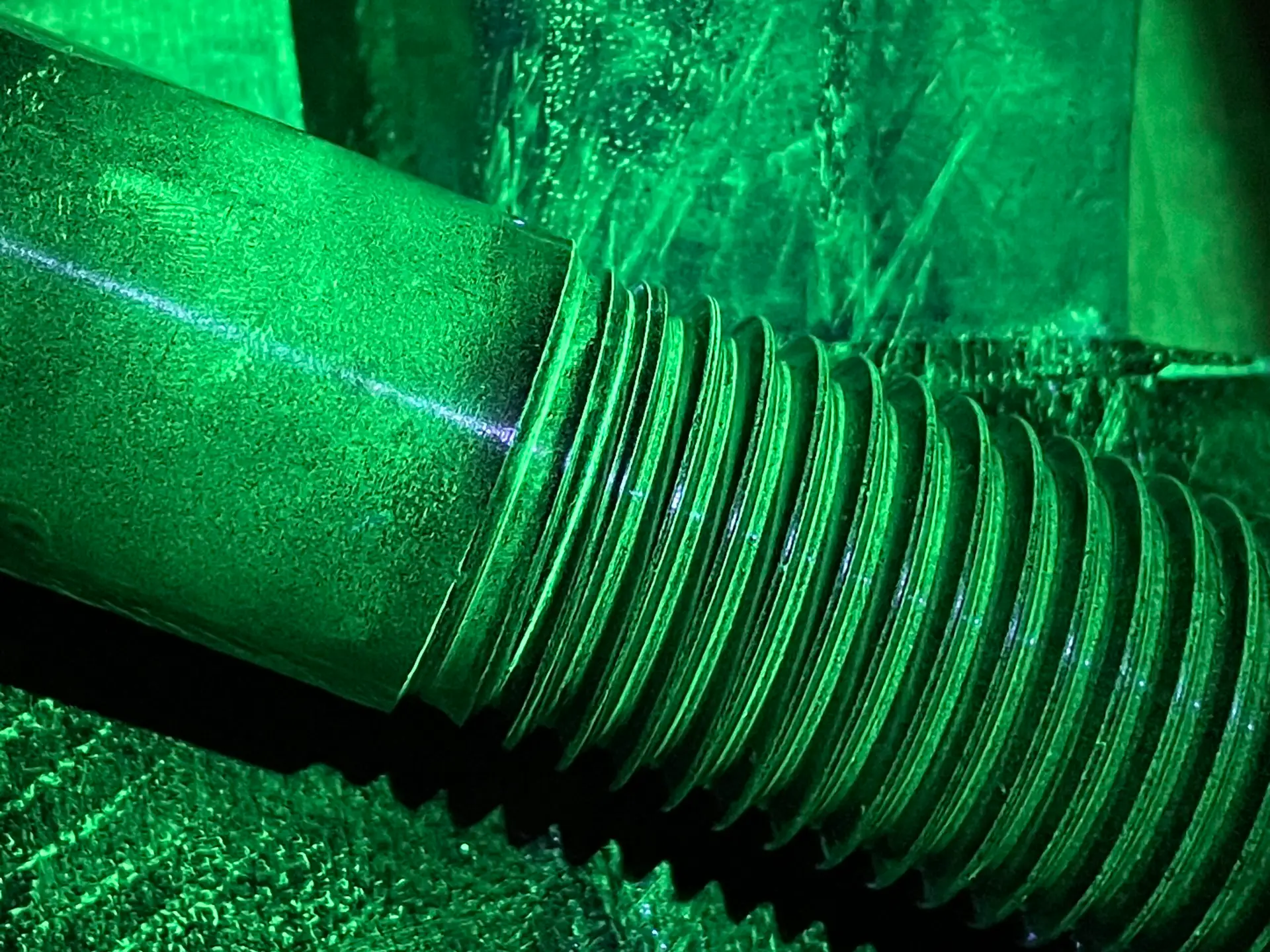

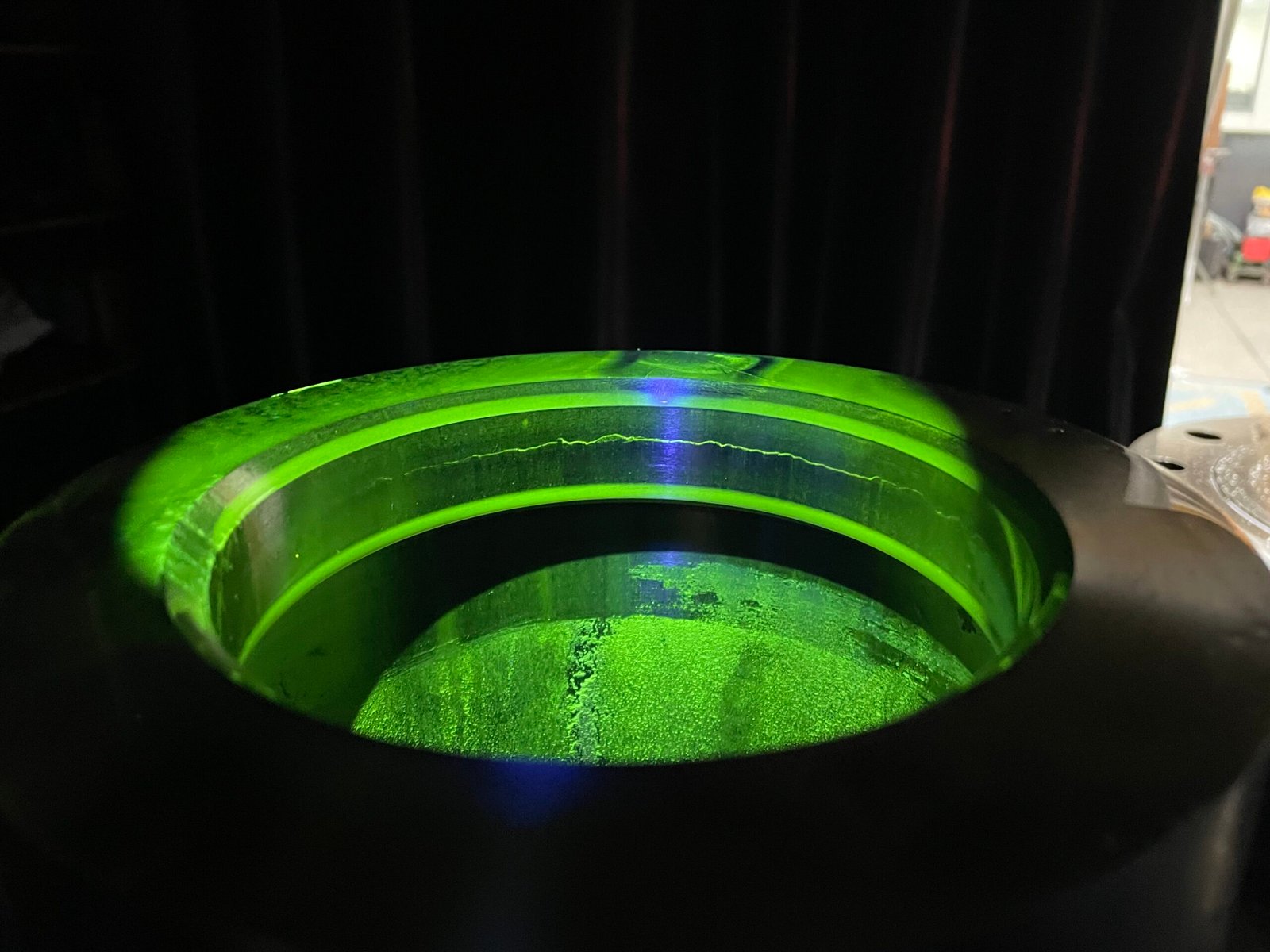

Penetrant Application – Applying a high-sensitivity liquid dye that seeps into any cracks or surface defects.

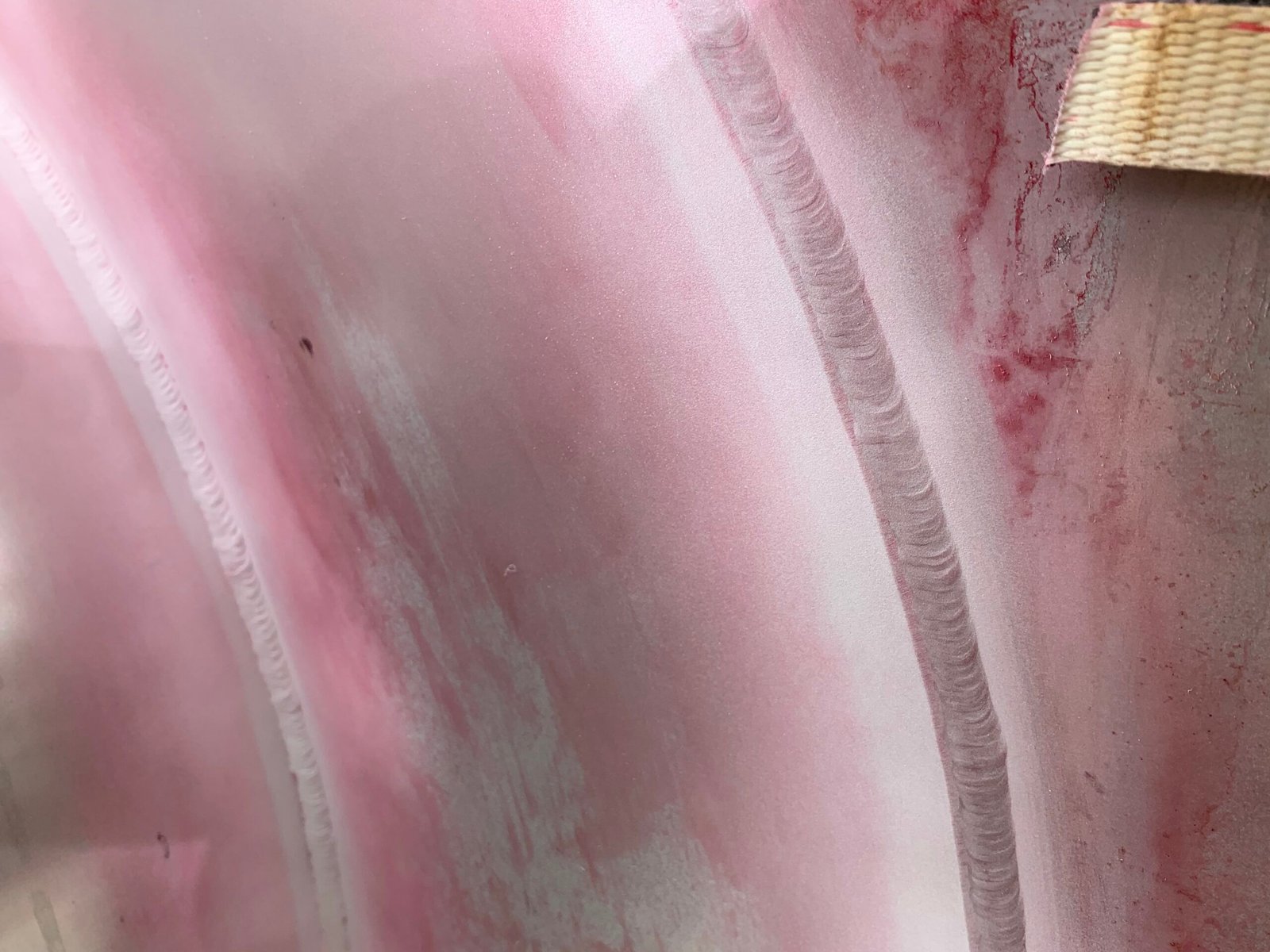

Excess Removal – Carefully wiping the surface while leaving dye trapped in flaws.

Developer Application – Applying a white developer coating that draws out the penetrant, revealing defects as visible indications.

Inspection – Conducting a visual inspection under proper lighting to identify and evaluate flaw size, type, and severity.

Benefits of Using DPI on Tank Manways

Non-destructive: No damage to the tank or welds.

Cost-effective: Quick setup and minimal downtime.

High sensitivity: Capable of detecting very fine cracks invisible to the naked eye.

On-site application: Ideal for installed manways without requiring dismantling.

This simple yet powerful method can reveal hairline cracks, porosity, and lack of fusion in welds that would otherwise go undetected.

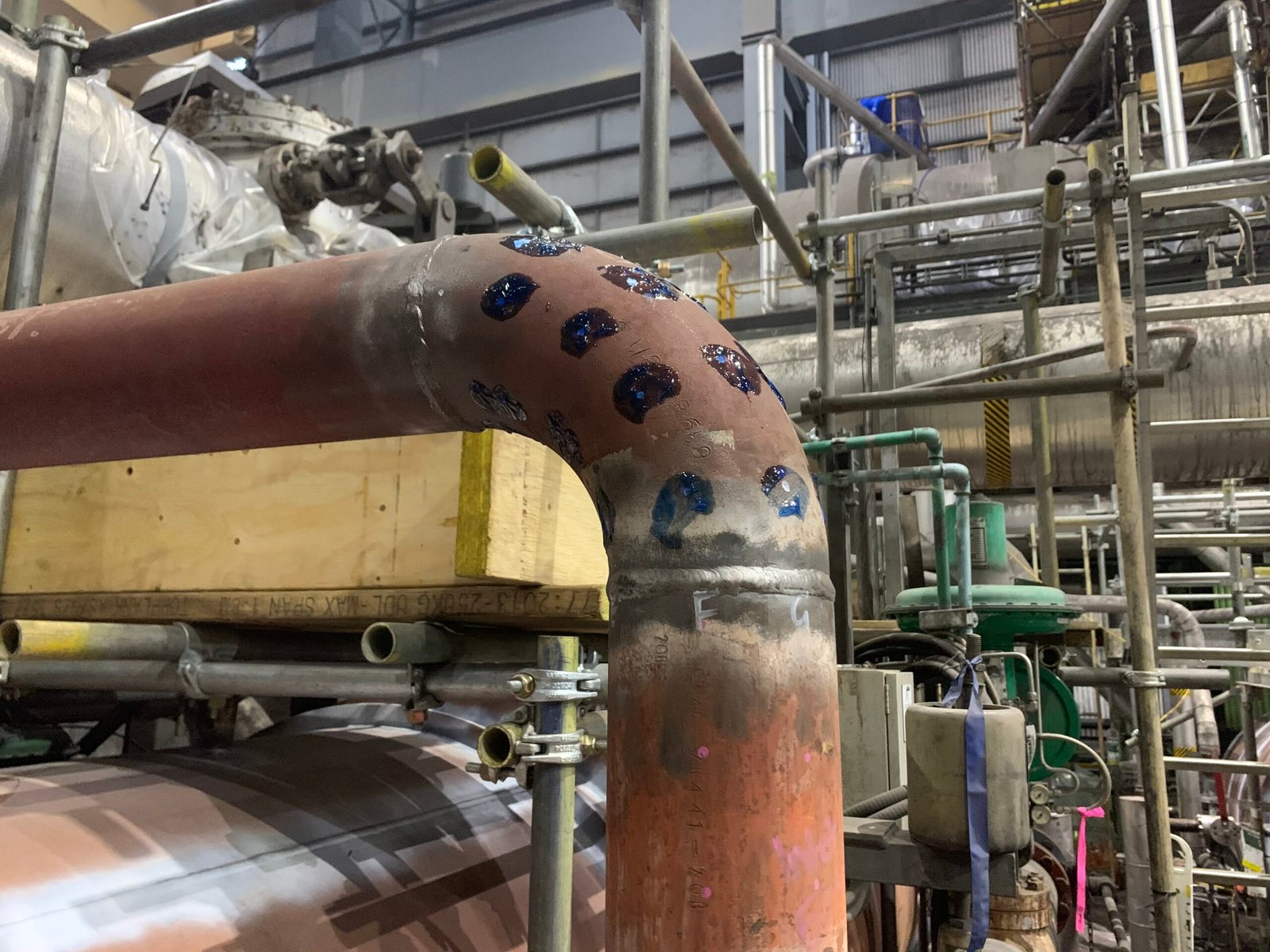

Real-World Applications

At Qualiss, we regularly perform PT on marine fuel tanks, chemical storage vessels, and pressure-retaining tanks where safety is non-negotiable. By targeting high-risk areas such as manways, operators gain confidence in the continued safe operation of their assets.

Tank manways are more than just access points — they are critical to operational integrity. By using Dye Penetrant Inspection (PT) after installation, industries can detect flaws early, prevent costly failures, and maintain compliance with safety standards.

If you require professional dye penetrant inspection services in Australia, Qualiss can help. Our certified inspectors deliver reliable results, ensuring your tanks remain safe, compliant, and fit for service.