Cracks in Welds: Detecting Hidden Risks with Ultrasonic Testing in Brisbane

Welds are essential for the safety and strength of industrial structures. Therefore, even small cracks can grow under stress, vibration, or repeated use, potentially compromising the entire structure. Fortunately, Ultrasonic Testing (UT) can detect these hidden flaws before they become a problem.

What Causes Cracks in Welds?

Cracks can develop during or after welding. For example, they may occur because of:

Remaining stress after welding (residual stress)

Improper welding technique or settings

Material defects or contamination

Repeated stress or bending over time (cyclic loading)

In addition, some common types of cracks include:

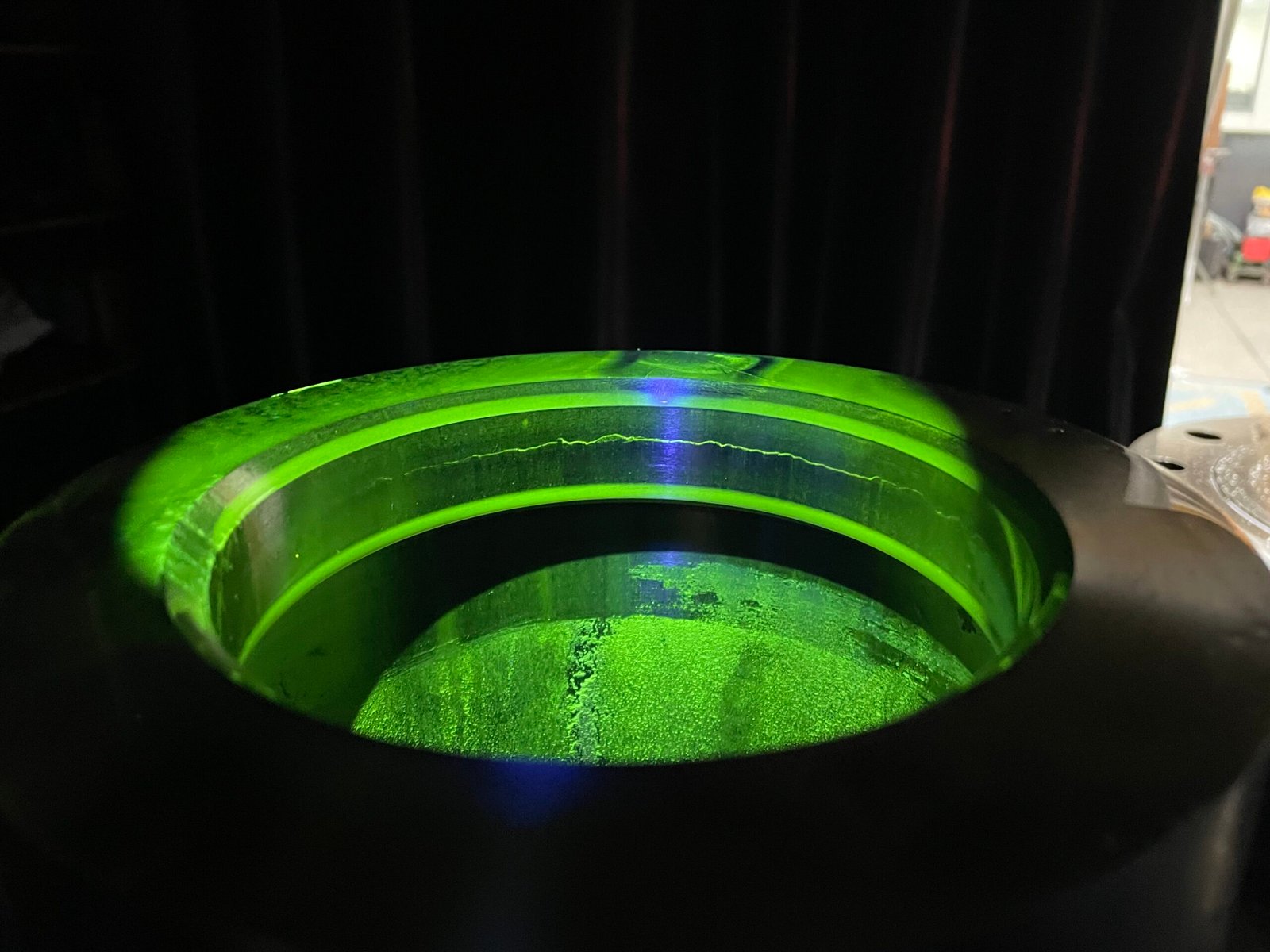

Inter-run cracks – cracks between layers of weld

End crater cracks – at the end of a weld

Toe cracks – cracks at the edge of the weld

Heat-affected zone cracks – cracks near the weld boundary

Although these cracks may look minor at first, leaving them unchecked can lead to serious failure. Consequently, early detection is crucial for safety and operational reliability.

Why Use Ultrasonic Testing for Weld Cracks?

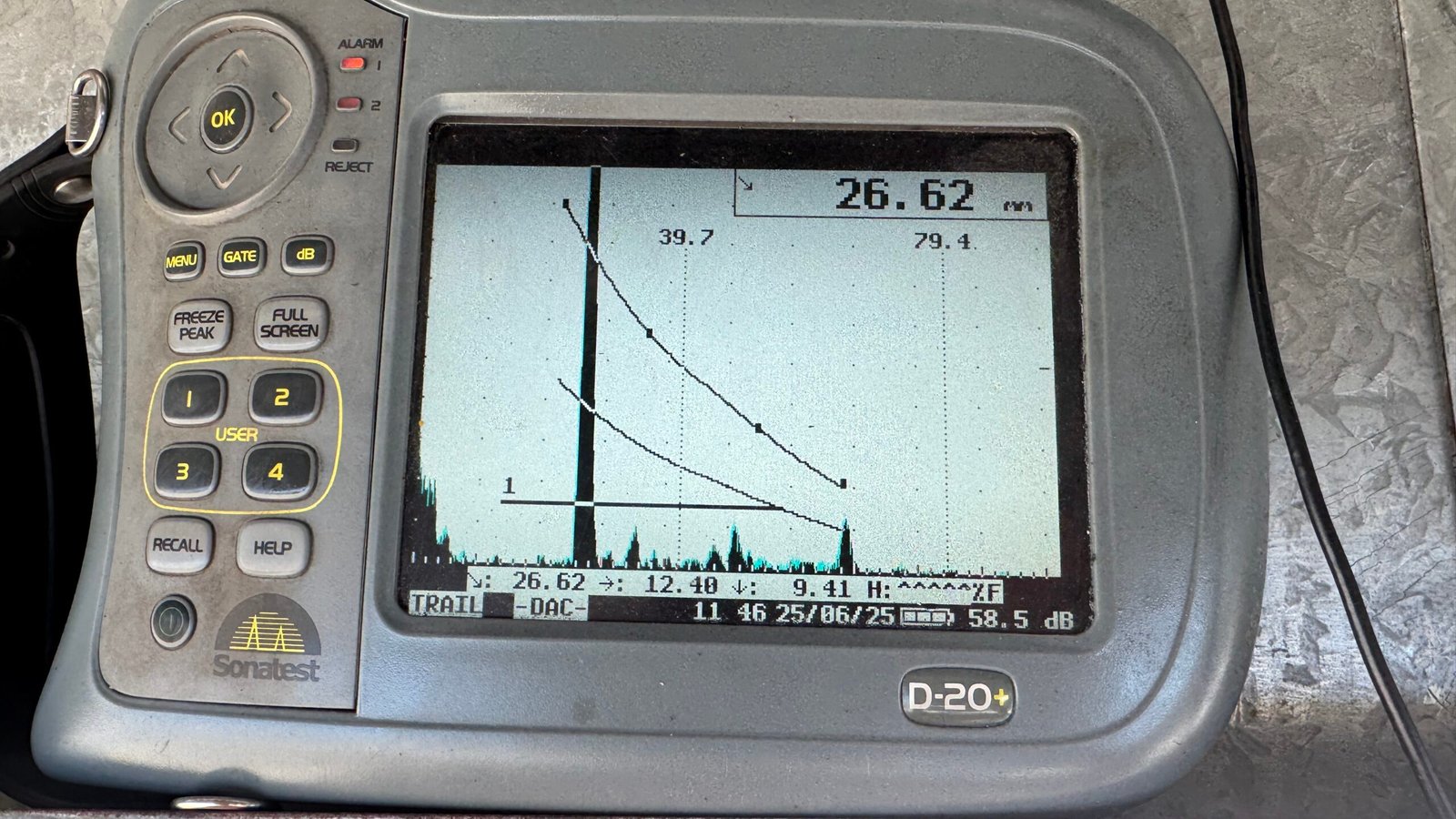

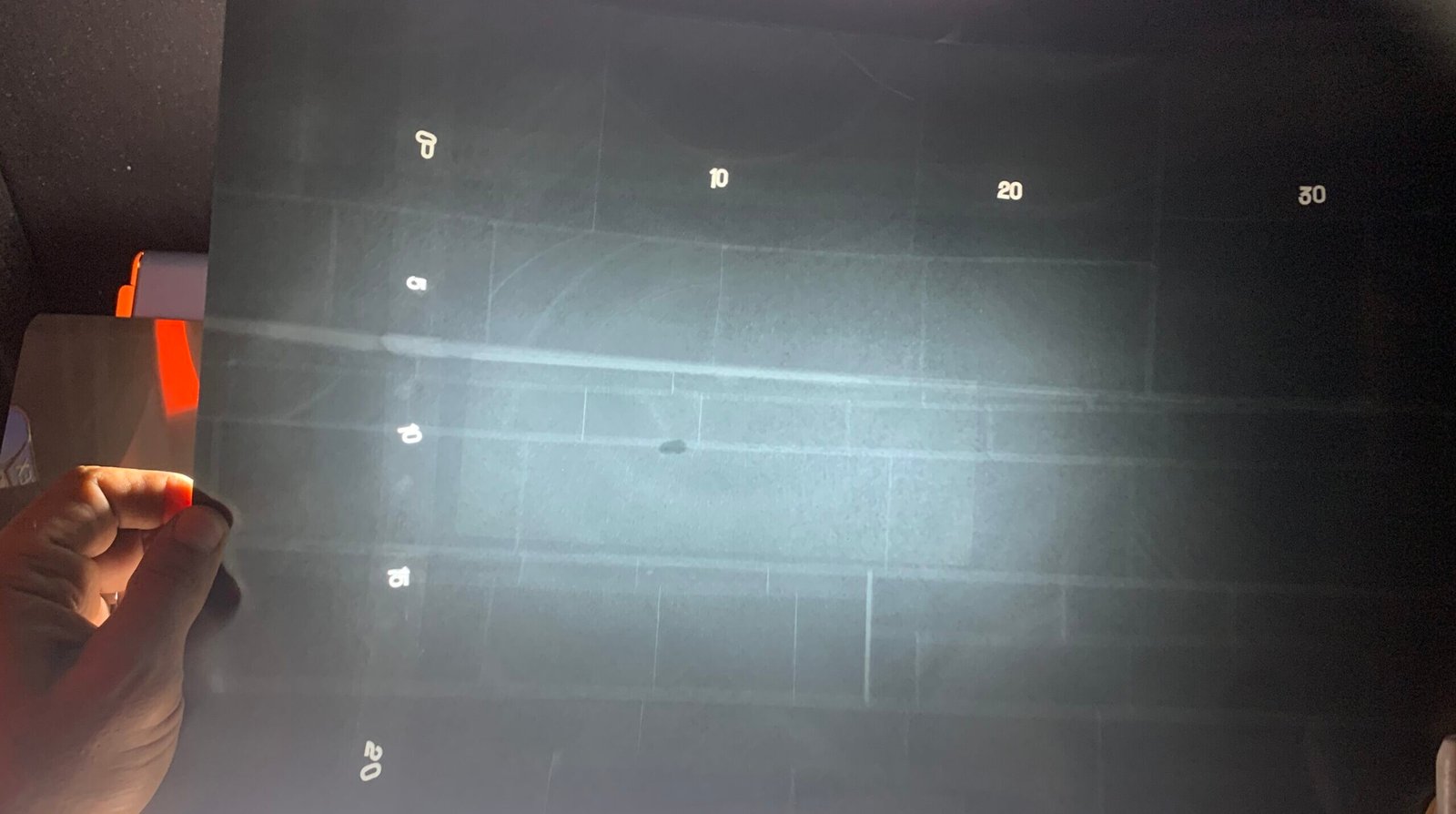

UT sends high-frequency sound waves into a weld to detect flaws beneath the surface. Unlike visual inspections or surface-only methods, UT can identify hidden cracks that would otherwise go unnoticed.

The key benefits of UT include:

Detecting internal and surface-breaking cracks

Measuring crack depth and size accurately

Inspecting thick sections and complex shapes

Being non-destructive — the weld stays intact

Safer than radiography because it uses no radiation

As a result, UT provides reliable information for maintenance planning. In addition, it helps engineers make informed repair decisions before problems escalate.

Industries That Benefit from UT Testing

Cracks in welds are a concern across many sectors. For instance:

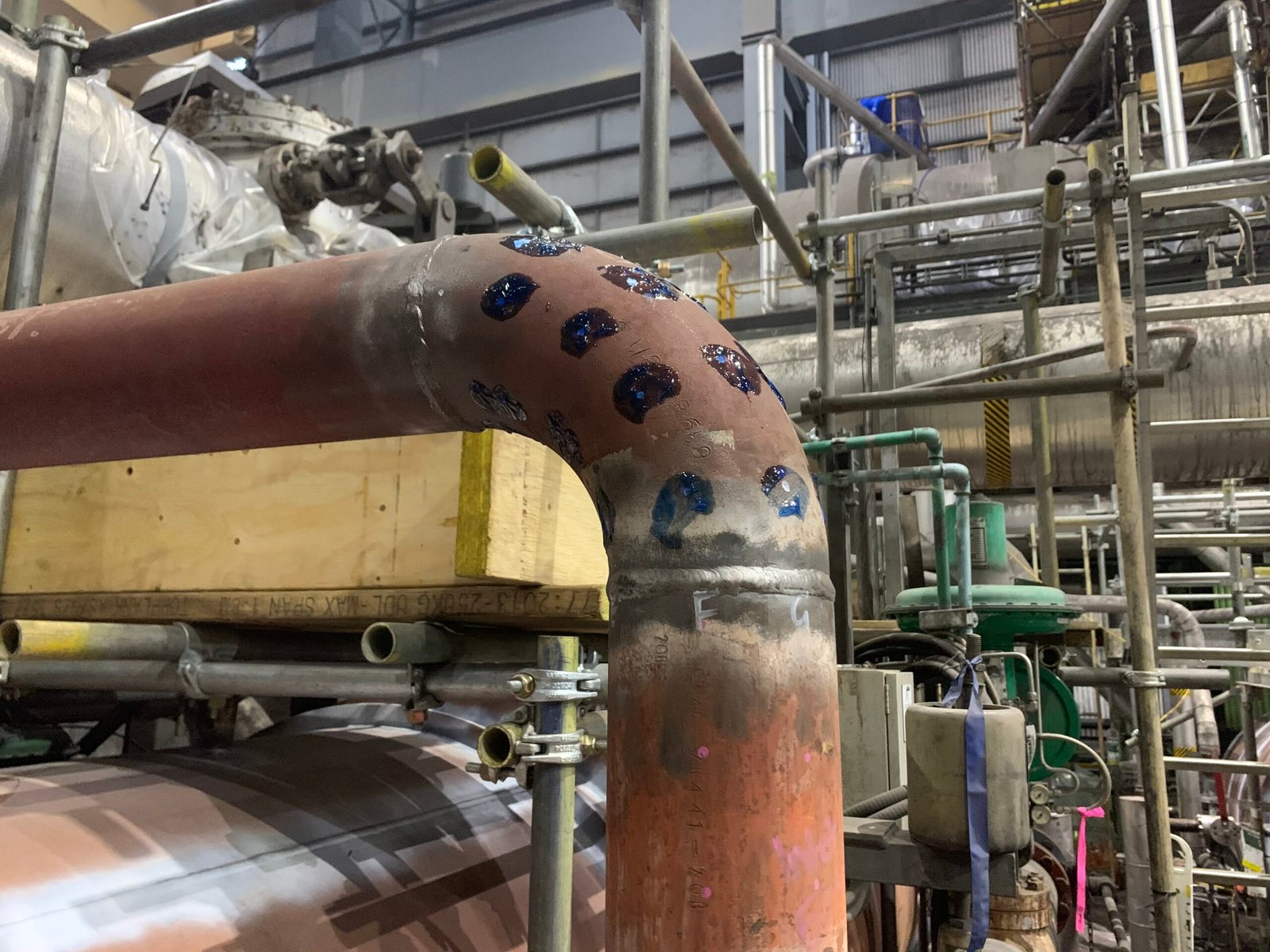

Mining & Energy – pressure vessels, pipelines, heavy machinery

Marine & Offshore – ship hulls, masts, subsea structures

Infrastructure – bridges, cranes, lifting equipment

Manufacturing & Construction – structural welds in heavy industry

Because welds carry significant loads, even small cracks can create safety and operational risks. Therefore, detecting them early is essential.

“Ultrasonic Testing penetrates beneath the surface, detecting internal weld cracks, porosity, and lack of fusion with precision and reliability”

Frequently Asked Questions about Ultrasonic Weld Testing (FAQ)

What kinds of cracks can UT detect?

UT detects inter-run cracks, toe cracks, end crater cracks, and other internal flaws invisible to the eye. In addition, it can locate cracks that are hard to reach with visual inspection alone.

Is ultrasonic testing safe?

Yes. Because UT uses sound waves instead of radiation, it is completely safe for people and the environment.

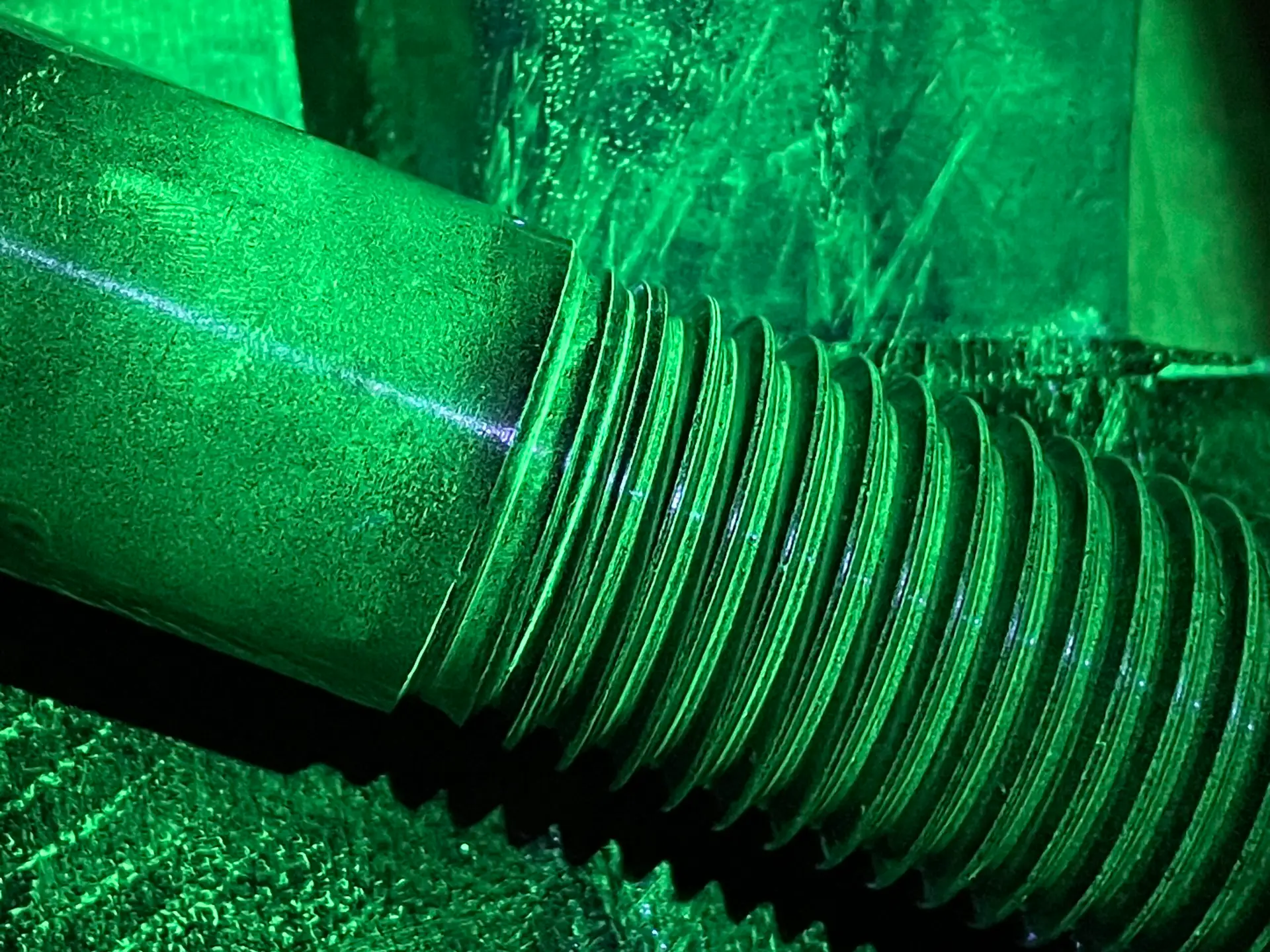

Can UT find surface cracks?

Yes, but UT is most effective for internal flaws. Therefore, for surface-only cracks, complementary methods like Magnetic Particle Inspection or Dye Penetrant Testing may be used.

How accurate is UT?

UT can detect very small cracks and measure their depth and length precisely. As a result, engineers can make well-informed repair decisions.

Do you provide reports?

Yes. Every inspection comes with a clear digital report outlining findings, measurements, and recommended actions.

Where do you offer ultrasonic testing?

We provide weld testing in Brisbane, South East Queensland, and across Australia. In addition, we offer flexible scheduling to suit your operational needs.