Crane inspection NDT

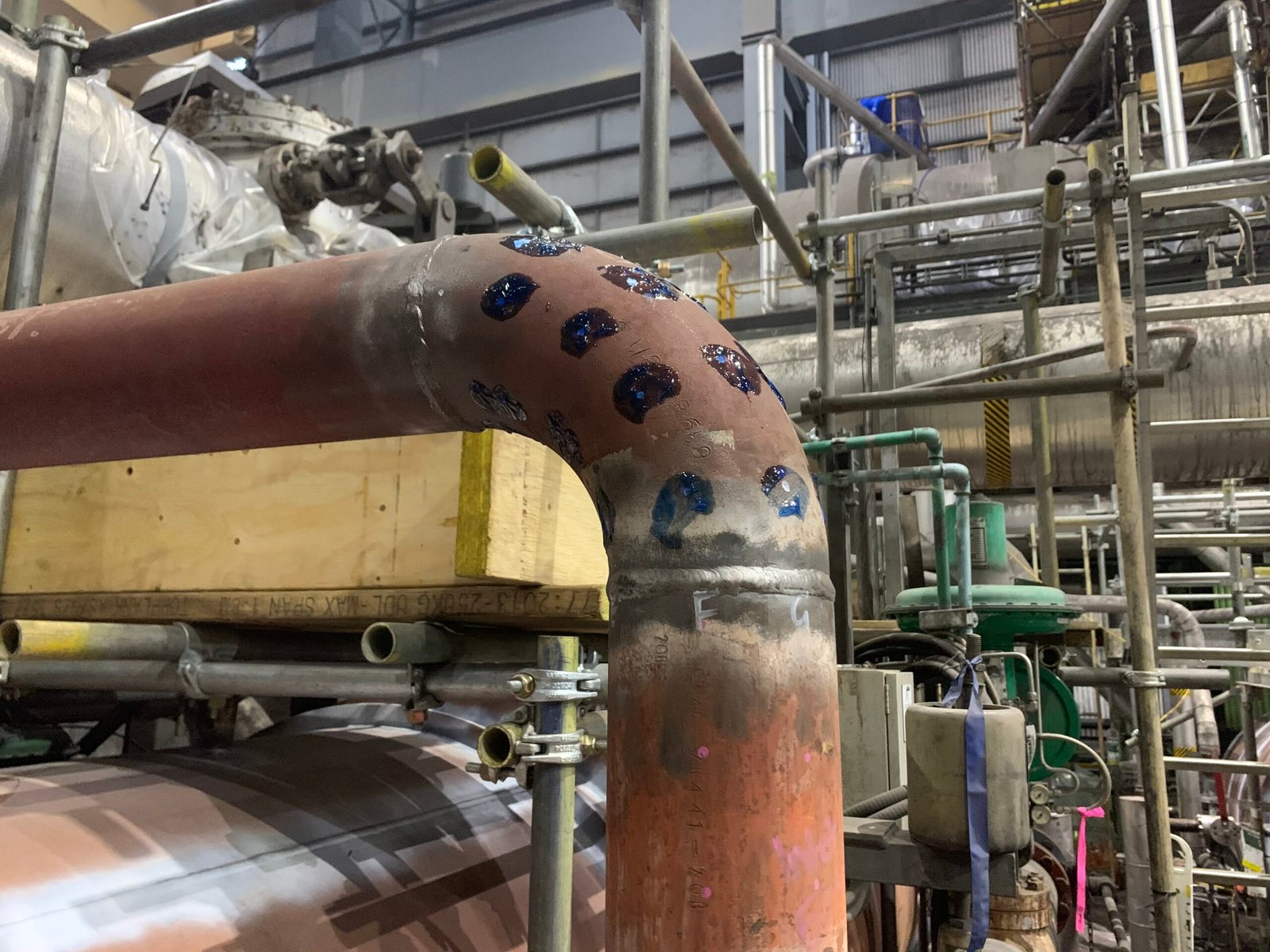

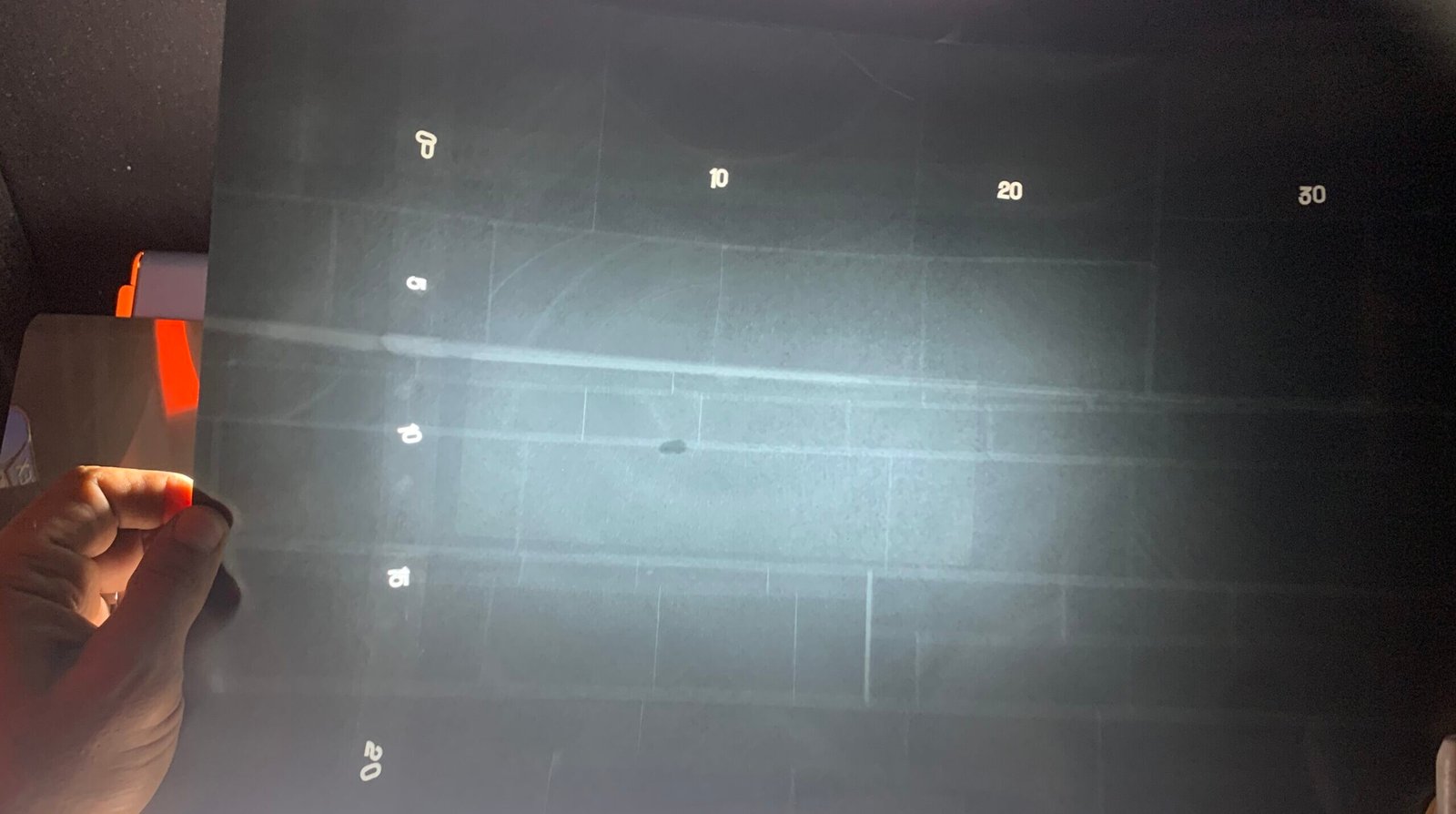

During a routine crane inspection on a truck-mounted Palfinger crane, our inspectors found a fine linear defect on a hydraulic cylinder near the welded transition. We then performed Magnetic Particle Inspection (MPI) and confirmed surface breaking cracks. Consequently, we removed the cylinder from service and recommended immediate repair or replacement to prevent a potential hydraulic failure.

What We Found During the Inspection

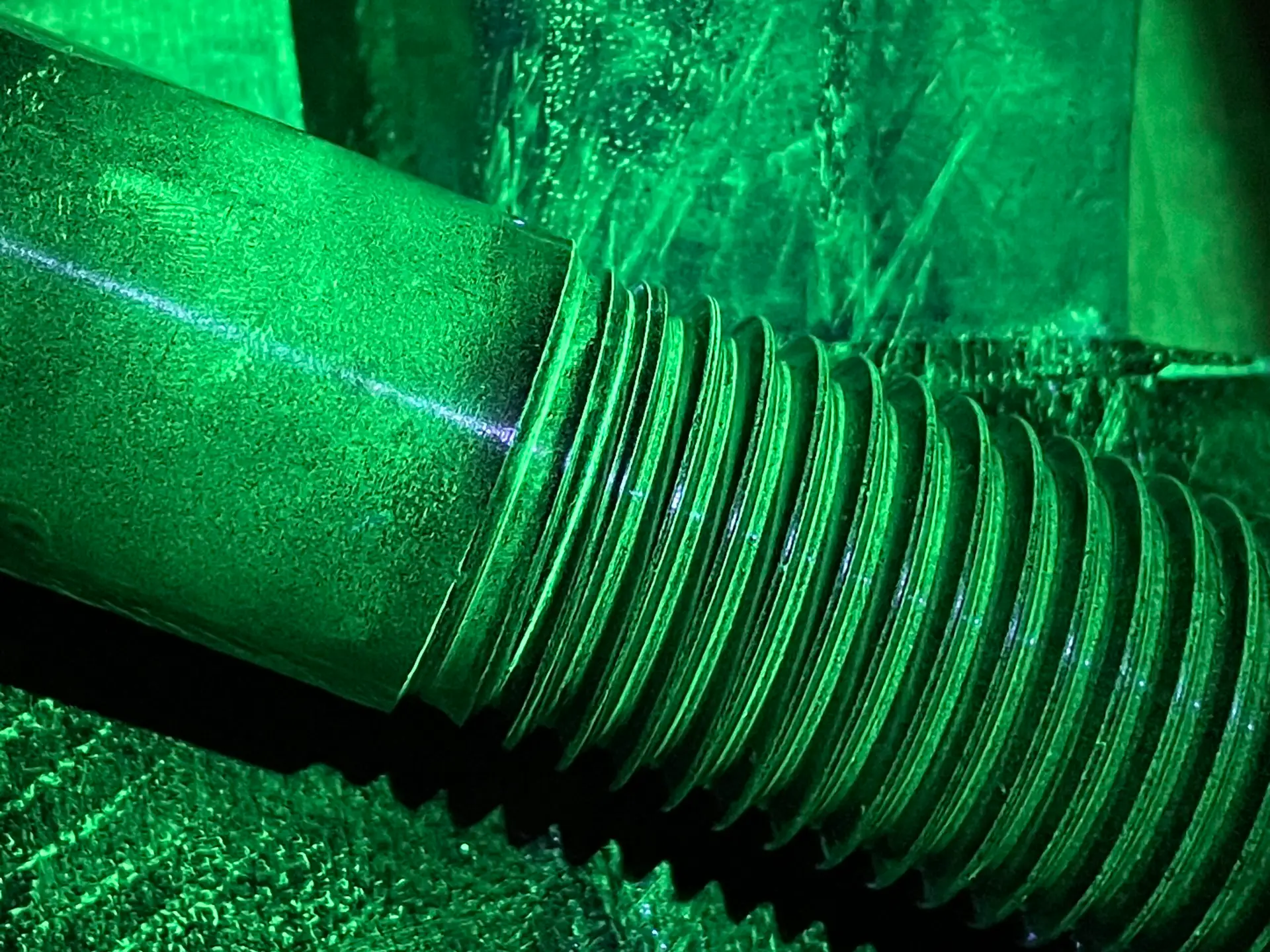

First, the visual check showed a subtle line in the paint and a small patch of rust at the cylinder end. Next, because visible marks can hide serious flaws, we cleaned the area and performed MPI. The MPI clearly revealed a surface crack running along the weld toe. In addition, the crack measured approximately X mm long (recorded on site) and followed the stress direction of the weld.

We documented the defect with high-resolution photographs and an MPI report, and then we advised the owner to take the crane out of service until the cylinder receives a certified repair or a manufacturer-approved replacement.

How Magnetic Particle Inspection Confirmed the Crack

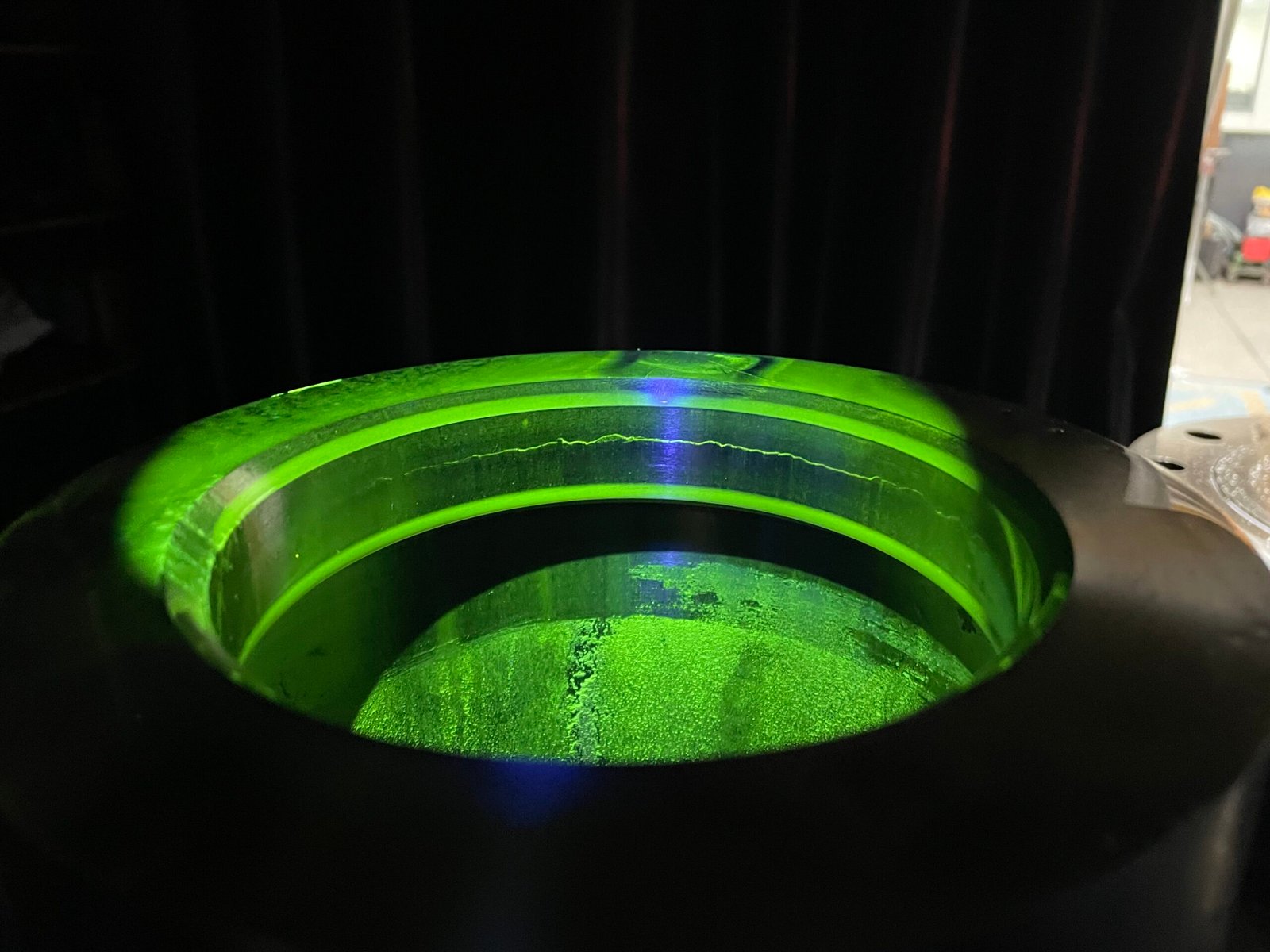

Magnetic Particle Inspection (MPI) is a non-destructive method for detecting surface and near-surface discontinuities in ferrous components. After preparing the surface by removing paint and corrosion, we magnetized the area and applied fluorescent magnetic particles. Under good lighting, the particles accumulated along the crack, confirming the defect.

MPI is fast, reliable, and widely used in crane inspection NDT for hydraulic cylinders, welds, and other high-stress areas.

Why Hydraulic Cylinders Crack

Hydraulic cylinders on loader cranes work hard. Daily extension, retraction, and load holding create repeated stress cycles. Common causes of cracks include:

Cyclic fatigue: Repeated loading causes tiny cracks to initiate and grow.

Stress concentrations: Weld toes, sharp corners, or poor blending increase local stress.

Corrosion: Rust weakens the metal and accelerates crack growth.

Shock or overloads: Exceeding rated capacity or sudden impacts propagate cracks.

Poor repairs or weld quality: Substandard welding or grinding introduces weak points.

Even small cracks can quickly worsen under pressure, making regular crane inspection NDT essential.

Risk and Consequences

Ignoring cylinder cracks can lead to:

Sudden loss of hydraulic pressure and uncontrolled boom movement

Dropped loads or boom collapse

Damage to the crane structure

Serious injury or worse to operators and bystanders

Because these risks are severe, defects must be addressed immediately.

“Visual inspections alone may overlook surface cracks or fatigue damage in crane hydraulic cylinders. Magnetic Particle Inspection (MPI) detects these defects accurately, ensuring safe, certified crane operation..”

Recommended Corrective Actions

Remove the crane from service until assessment is complete

Document the defect with measurements, photos, and MPI reports

Consult the OEM or certified repairer (Palfinger or approved facility)

Repair or replace the cylinder:

Repairs must follow OEM welding and stress-relief standards

Replacement is preferred if cracks are in critical load-bearing areas

Inspect similar components for systemic fatigue issues

Update maintenance records with NDT reports and corrective actions

Review operational practices to prevent recurrence, including load management and corrosion protection

Why Regular Crane Inspection NDT Matters

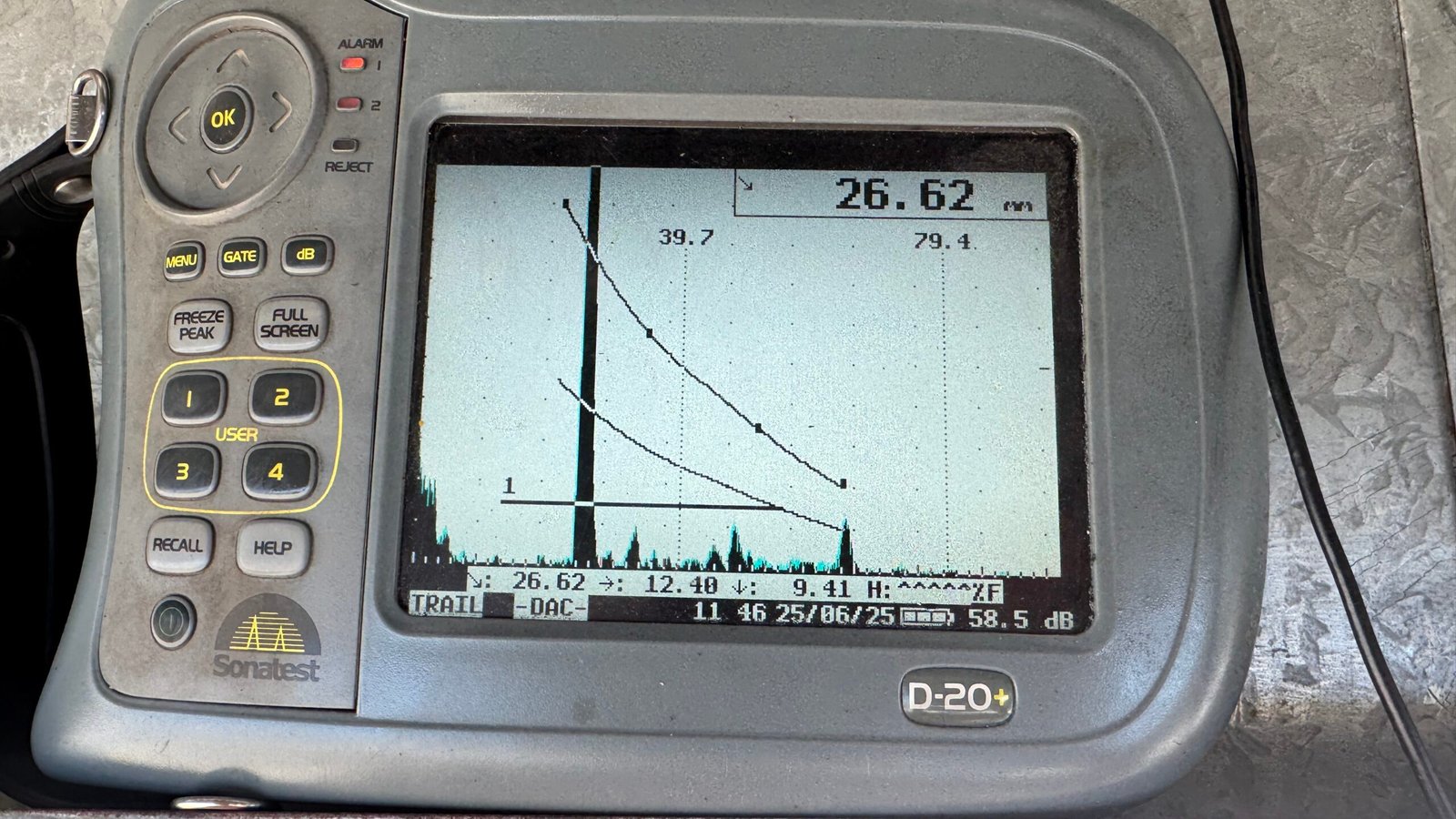

Regular crane inspection NDT prevents hidden defects from becoming emergencies. MPI and UT reveal cracks and weaknesses invisible to the naked eye, protecting operators and ensuring reliable crane operation.

Learn more about crane safety from Safe Work Australia

Check OEM guidance at Palfinger

For more structural inspections, see our 10-Yearly Crane Testing article. Learn about complementary NDT services on our Ultrasonic Testing and Digital Radiography pages.

Crane inspection NDT (Non-Destructive Testing) is a method of examining crane components, like hydraulic cylinders and welds, for hidden defects without causing damage. Techniques include Magnetic Particle Inspection (MPI) and Ultrasonic Testing (UT).

Hydraulic cylinders undergo repeated loading, pressure fluctuations, and stress at welds and transition points. Factors like fatigue, corrosion, shock loads, and poor weld quality can cause surface or subsurface cracks.

MPI detects surface and near-surface cracks in ferrous metals. The area is magnetized, magnetic particles are applied, and defects become visible under UV or normal light. It’s a fast, reliable NDT method for crane inspections.

Ignoring cracks can lead to hydraulic failure, uncontrolled boom movement, dropped loads, crane collapse, and serious injury or property damage.

Regular inspections are recommended annually, with a more detailed NDT performed every 10 years or as required by manufacturer guidelines and Australian standards like AS 2550.

Defective cylinders are removed from service immediately. Depending on severity, the cylinder is repaired following OEM standards or replaced. Other similar components are also checked to prevent systemic failure.

Yes. By detecting hidden cracks and weaknesses before they fail, NDT helps maintain crane safety, prevents costly downtime, and protects operators and nearby personnel.