Introduction

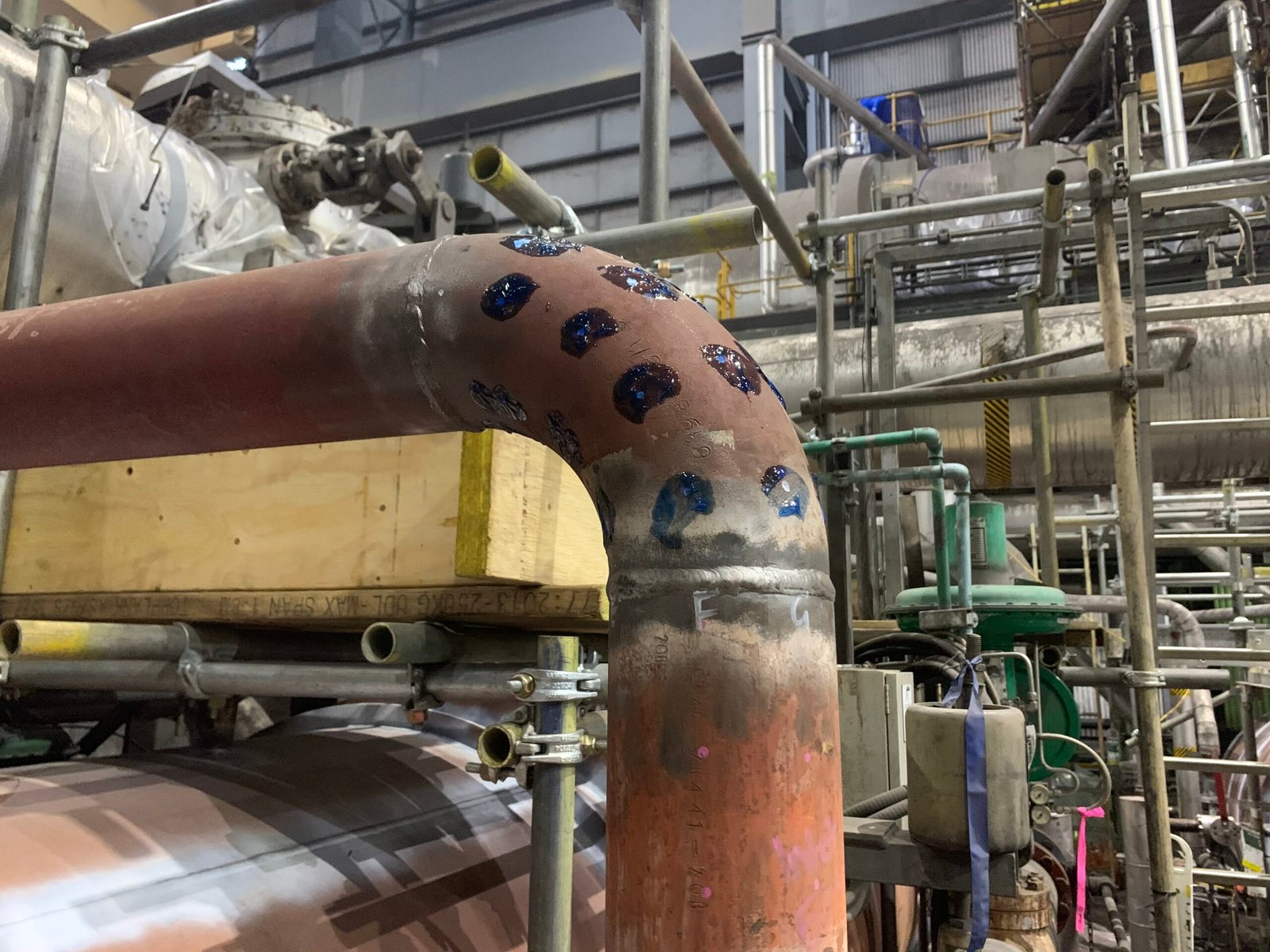

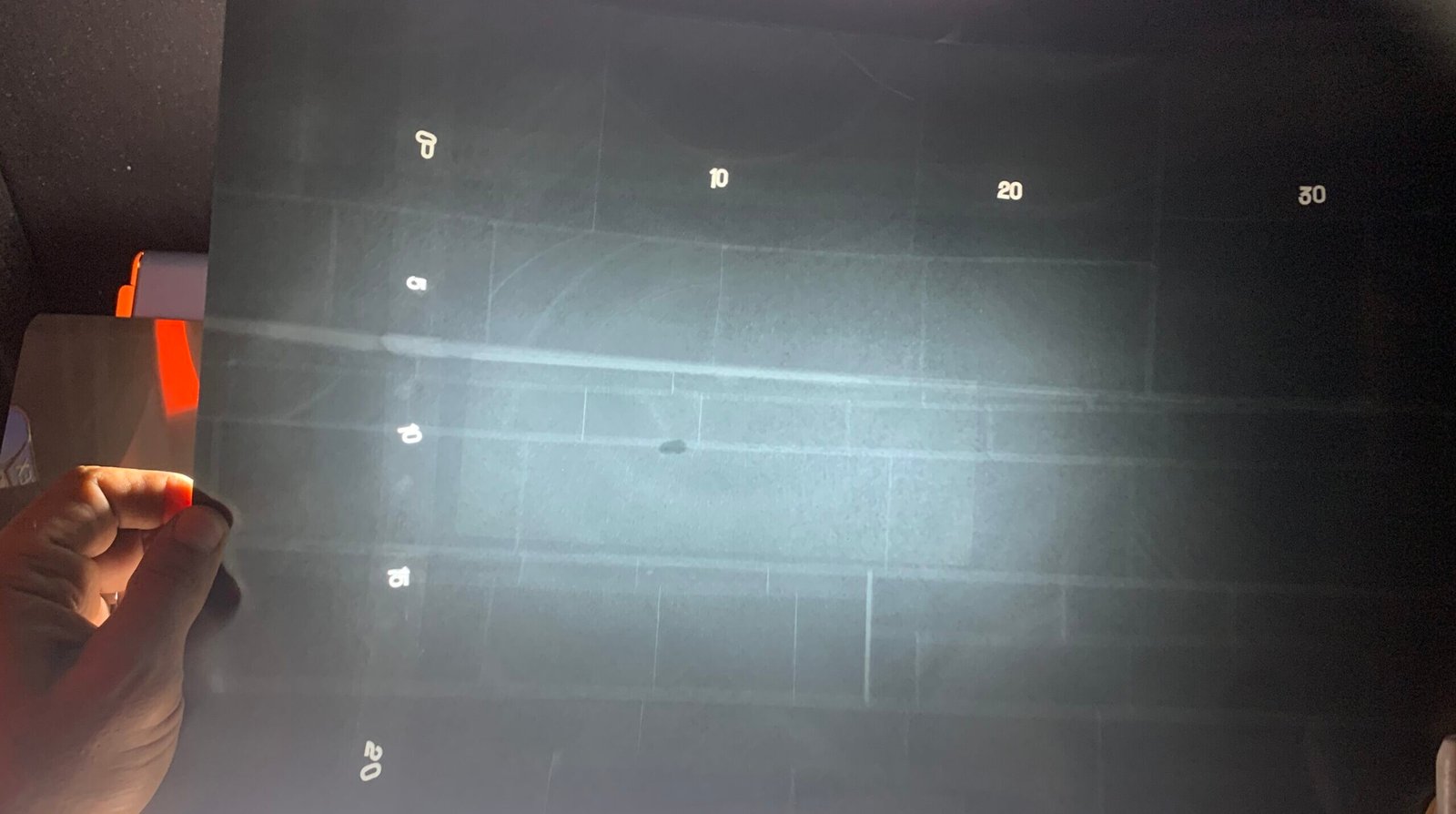

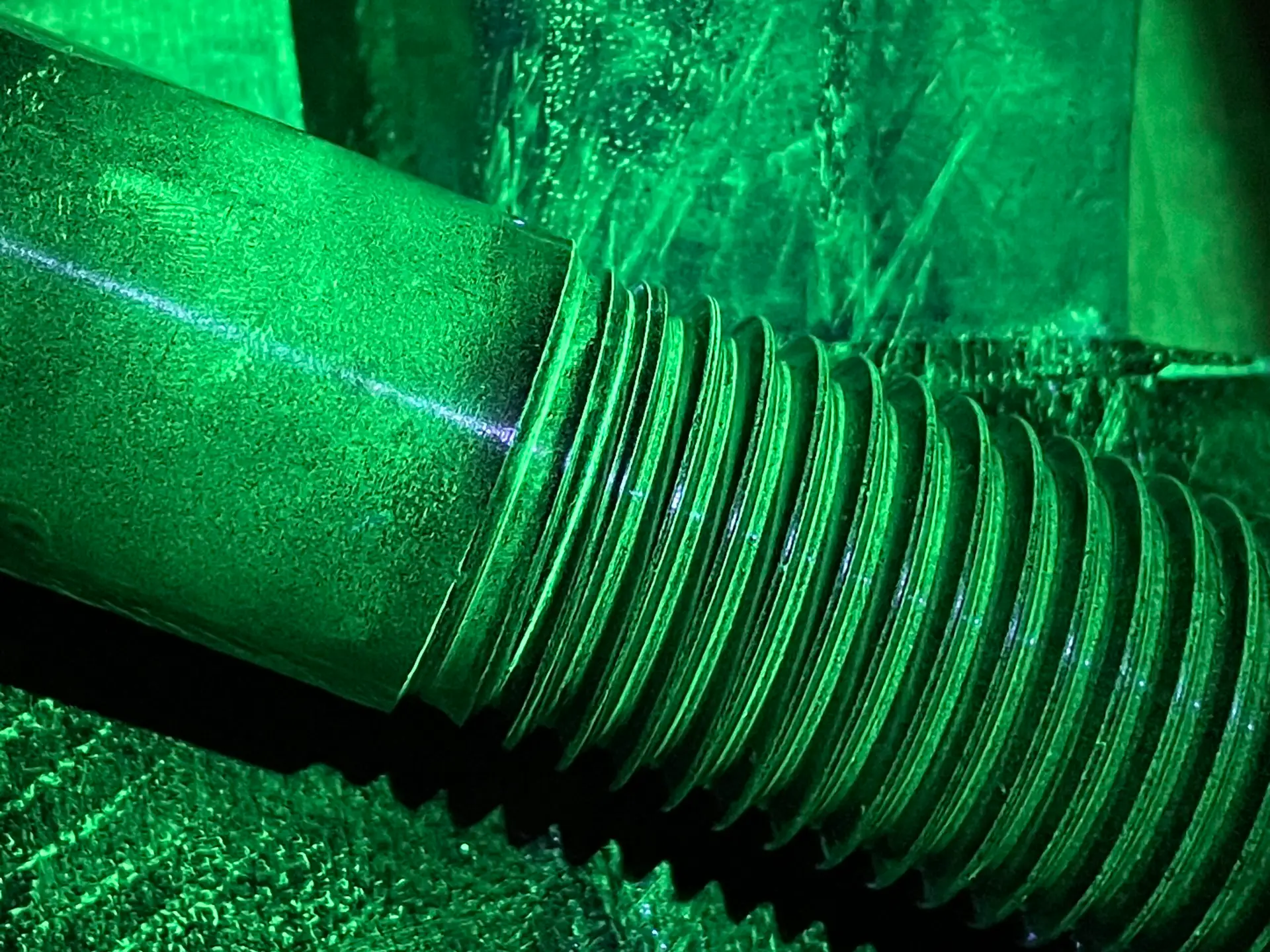

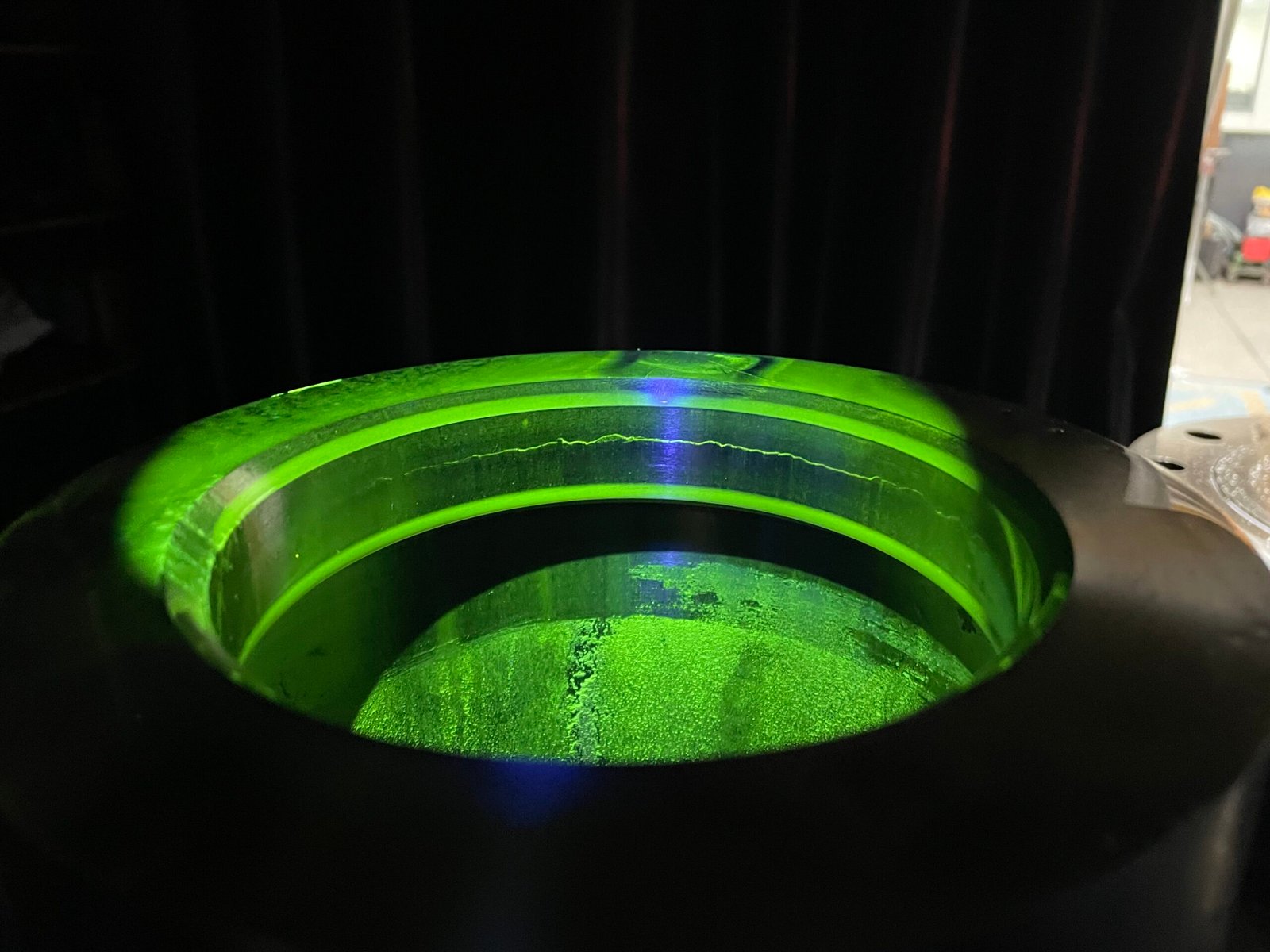

During a recent Condensate Return Line Inspection at a Queensland paper mill, our team identified a fine crack in a flange caused by corrosion and thermal cycling. The discovery demonstrated how early visual inspections prevent costly downtime and ensure safe operation of critical condensate systems.

Why Visual Inspections Come First

Visual inspection (VT) consistently delivers the earliest, lowest-cost warning of trouble. First, we look for rust runs, discolouration, weeping, or hairline lines near weld toes and flange faces. Next, we verify lighting and magnification to avoid missed indications. As a result, we catch defects before they escalate into leaks, failures, or shutdowns.

Condensate Return Lines: Conditions That Drive Cracking

Condensate lines return hot condensate to the boiler in a closed loop. Consequently, they endure cyclic temperature and pressure, plus chemistry that can attack metal surfaces. Typical degradation mechanisms include:

Thermal cycling: expansion/contraction initiates fatigue at stress raisers.

Corrosion under insulation (CUI): trapped moisture drives pitting beneath lagging.

Erosion/corrosion: high-velocity condensate thins elbows and reducers.

Galvanic effects: dissimilar metals at repairs accelerate local attack.

Over time, these factors create micro-cracks that grow at flange faces, weld toes, and bolt holes—especially where vibration and misalignment add load.

Carbonic Corrosion in Condensate Systems

Carbonic corrosion is one of the most common forms of chemical attack in steam and condensate systems. It occurs when carbon dioxide (CO₂) dissolves in condensate water, forming carbonic acid (H₂CO₃). This weak acid lowers the pH and aggressively attacks the steel surface, creating a rough, grooved appearance often called channeling. The risk increases when condensate cools or remains stagnant, allowing CO₂ to accumulate. Over time, carbonic corrosion thins the pipe wall, weakens welds, and promotes cracking—particularly in elbows, reducers, and return line flanges. Routine visual inspections combined with pH control, proper venting, and condensate treatment are essential to mitigate this silent but destructive process.

From VT to NDT: Confirming and Quantifying Risk

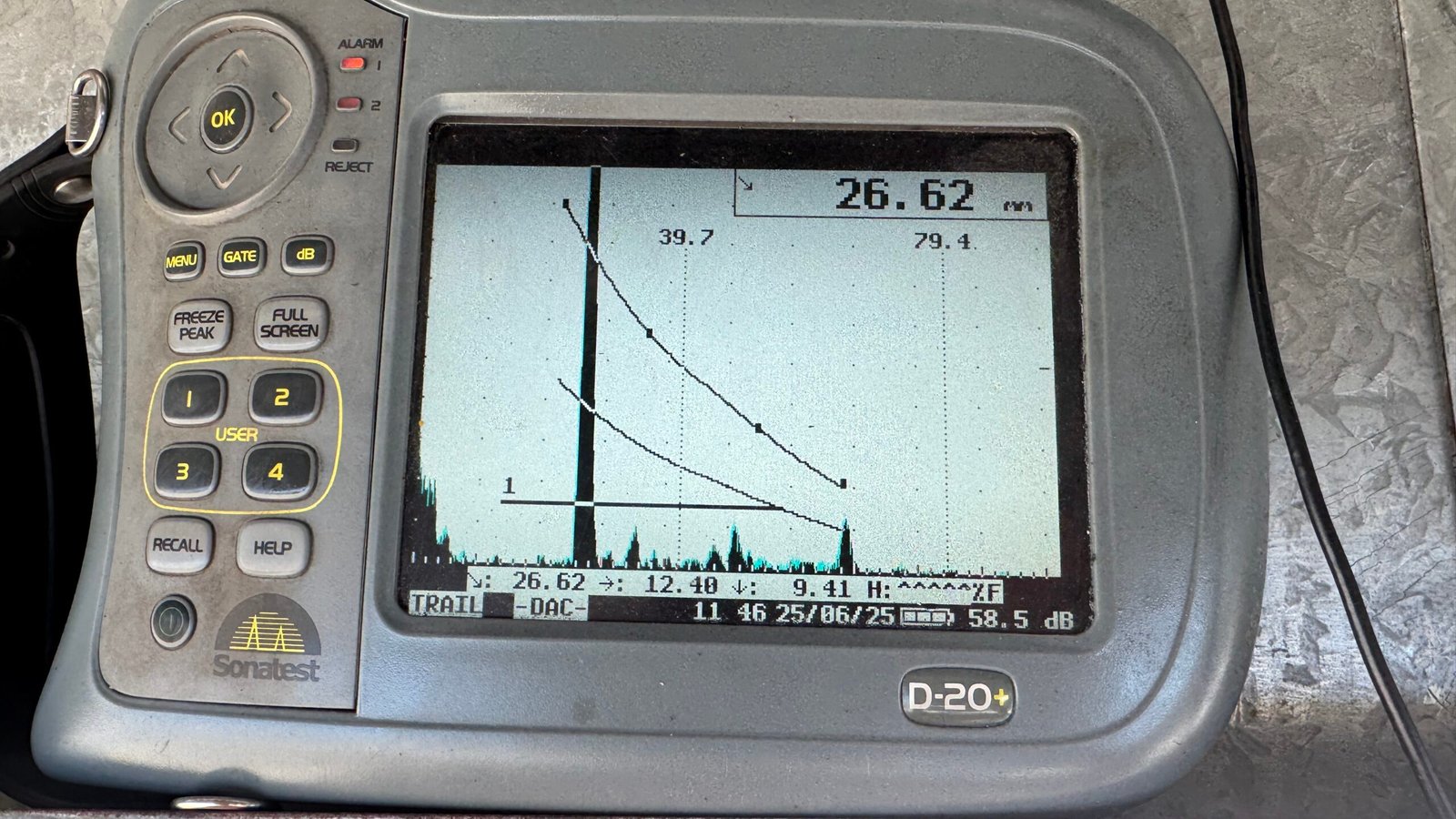

Visual findings guide the next step. When we suspect surface-breaking defects, we perform Dye Penetrant Inspection (PT) to expose tight cracks on stainless or non-magnetic alloys. If the item is ferromagnetic, Magnetic Particle Inspection (MT) works well. To assess remaining life, we add Ultrasonic Testing (UT) for wall loss and flaw sizing.

Learn more about our methods: Ultrasonic Testing and Dye Penetrant Inspection.

“Condensate return lines work quietly under heat and pressure—until corrosion speaks. Routine inspection turns whispers of fatigue into early action, not costly failures.”

Recommended Response When You Find a Crack

Record exact location with photos and a sketch.

Isolate and depressurise the line if risk warrants.

Clean and re-inspect; confirm with PT/MT and measure thickness with UT.

Repair or replace the flange per OEM/code; align spools to minimise stress.

Re-test after repair and update the inspection plan.

Mitigate causes: improve drainage, upgrade insulation, and review chemistry.

Compliance and Competency

We align inspections with AS/NZS 3788 inspection principles for pressure equipment and use technicians certified to ISO 9712. This combination supports defensible decisions and audit-ready records. See ISO 9712 and the AS/NZS 3788 listing on the standards infostore.

Key Takeaways

Visual inspection detects problems first; it’s fast, scalable, and cost-effective.

Condensate return lines face corrosion and fatigue from thermal/pressure cycles.

Flanges are stress hubs; small cracks can escalate quickly.

Targeted NDT (PT/MT/UT) confirms the defect and informs repair.

Proactive action reduces downtime, risk, and total cost.

Routine visual checks revealed subtle rust tracking and a hairline indication at a flange.

Thermal cycling, corrosion (including CUI), and vibration create fatigue at stress concentrations.

PT or MT for surface cracks; UT for thickness and flaw monitoring.

Treat it as high priority: isolate, confirm with NDT, and repair or replace under code.

Technicians certified to ISO 9712; inspections aligned to AS/NZS 3788 principles.

Improve insulation details, drainage, alignment, supports, and water treatment.

A documented assessment with photos, NDT results, and repair/testing recommendations.