AS 3788:2024 — The Complete Queensland Guide to In-Service Inspection of Pressure Equipment

When pressure equipment fails, it’s rarely small. AS 3788:2024 exists to keep boilers, air receivers, pressure vessels, heat exchangers and piping safe, reliable, and legally defensible throughout their entire life. This guide translates the standard into plain English with a Queensland focus—what’s in scope, how to build a compliant inspection plan, how to set intervals the right way, which NDT to pick, and how to present records that satisfy WorkSafe Queensland.

Whether you run a single workshop compressor or a complex plant with multiple boilers and exchangers, you’ll get a practical blueprint you can implement this week.

What AS 3788 covers

AS 3788 sets the minimum requirements for in-service inspection of pressure equipment after it’s installed and commissioned. In practice, it tells you:

What to inspect (external/operational checks, close-ups, internals, NDT, and where justified, pressure tests).

How often to inspect (time-based or risk-based intervals).

How to decide fitness-for-service (continue, restrict, repair/replace, or re-rate).

How to manage changes (repairs, modifications, alterations, re-rating).

What to record (plans, procedures, results, recommendations, actions, and evidence of closure).

AS 3788 aligns with—and is often used alongside—other Australian standards for maintenance, valve testing and specific equipment types. Treat it as the framework that guides your decisions and the evidence file you’ll show an auditor.

Who this guide is for

Owners and operators of boilers, air receivers, vessels, exchangers and piping.

Maintenance and reliability teams responsible for inspection planning and execution.

NDT providers and inspection bodies who need to align scopes and reports with AS 3788.

Project and shutdown planners who must schedule openings, NII and PSV work without unnecessary downtime.

How Queensland compliance fits in

Queensland requires plant registration for certain pressure equipment, typically aligned to hazard levels (AS 4343). Registration, inspection plans, PSV certificates and UT trending are common audit focal points. If you don’t know the hazard level, have a competent person determine it from design and operating data.

Audit tip: Regulators assume “not documented = not done.” Keep a clean paper trail: plan → work pack → report → actions → close-out evidence.

Time-based vs risk-based inspection

Time-based inspection (TBI) uses standard intervals (e.g., annual external, periodic internals) that suit many sites with straightforward duty. It’s predictable and easy to schedule.

Risk-based inspection (RBI) tailors scope and interval based on the real risk (probability × consequence) for each item. Good RBI focuses attention (and budget) on high-risk equipment while avoiding unnecessary opening of low-risk items.

How to pick:

Choose TBI for simple services, limited history, or when you’re building a program from scratch.

Choose RBI where you have varied services, strong condition data, or costly openings; RBI usually pays for itself in fewer unplanned outages and more targeted work.

Setting and adjusting inspection intervals

Intervals are engineering decisions, not calendar habits. Build them from:

Service understanding — pressure, temperature, fluid, contaminants, start/stop cycles, upsets.

Credible damage mechanisms — identify what could actually happen in your service (e.g., CUI, SCC, erosion-corrosion, fatigue).

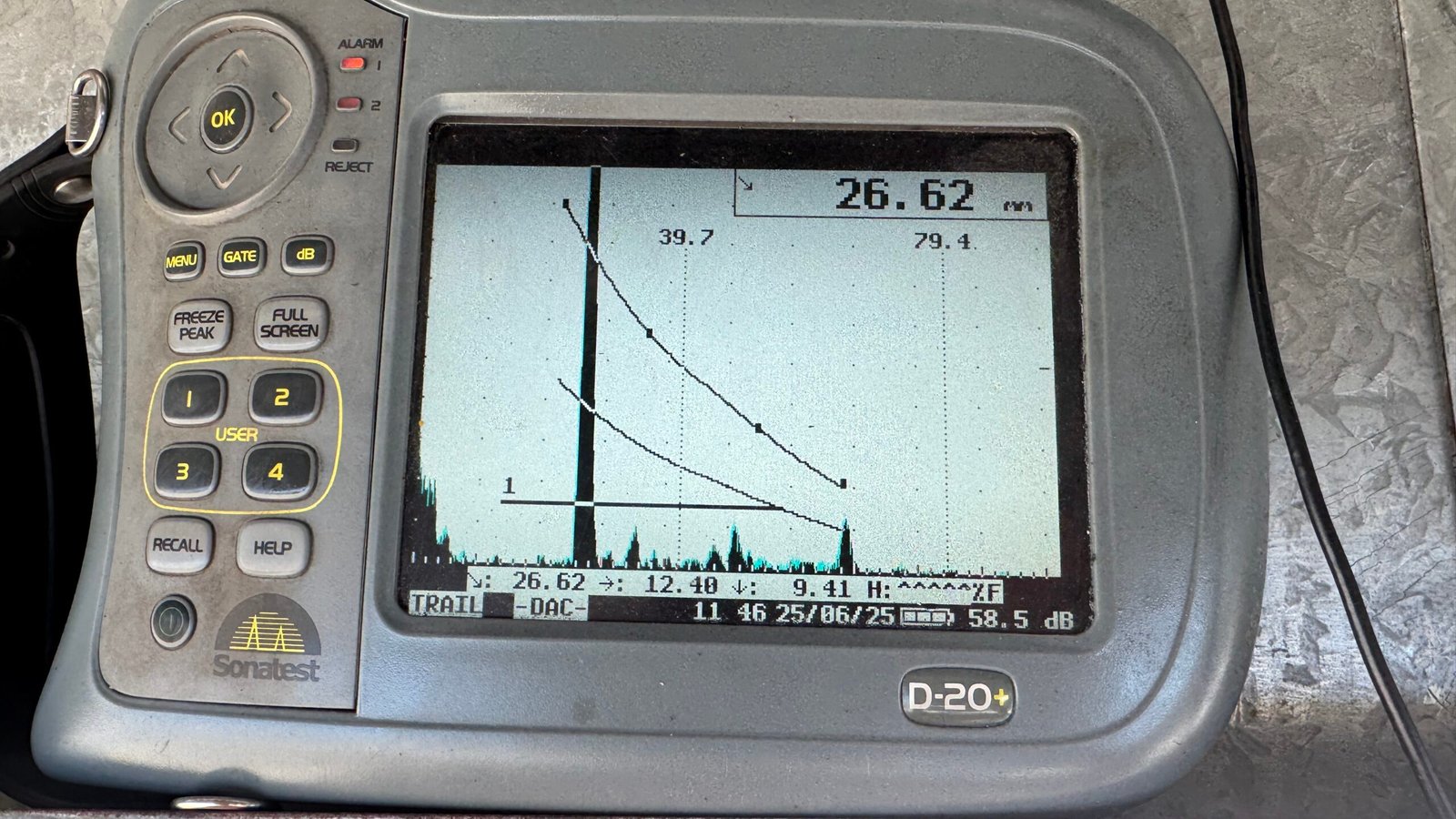

Technique suitability — pick methods that will detect that specific damage where it’s most likely to occur.

Evidence — UT trends, corrosion rates, leak/failure history, chemistry and water management, coating/insulation condition, PSV test records.

Adjusting intervals:

If data shows stable, predictable degradation and strong protections, you may extend (with documented rationale).

If you see accelerating corrosion, new pitting, cracking or barriers not performing, shorten until risk is under control.

Deferrals to align with shutdowns can be acceptable if you demonstrate stable conditions and add temporary checks (e.g., opportunistic UT). Keep them short, justified and logged.

Non-intrusive inspection (NII) the right way

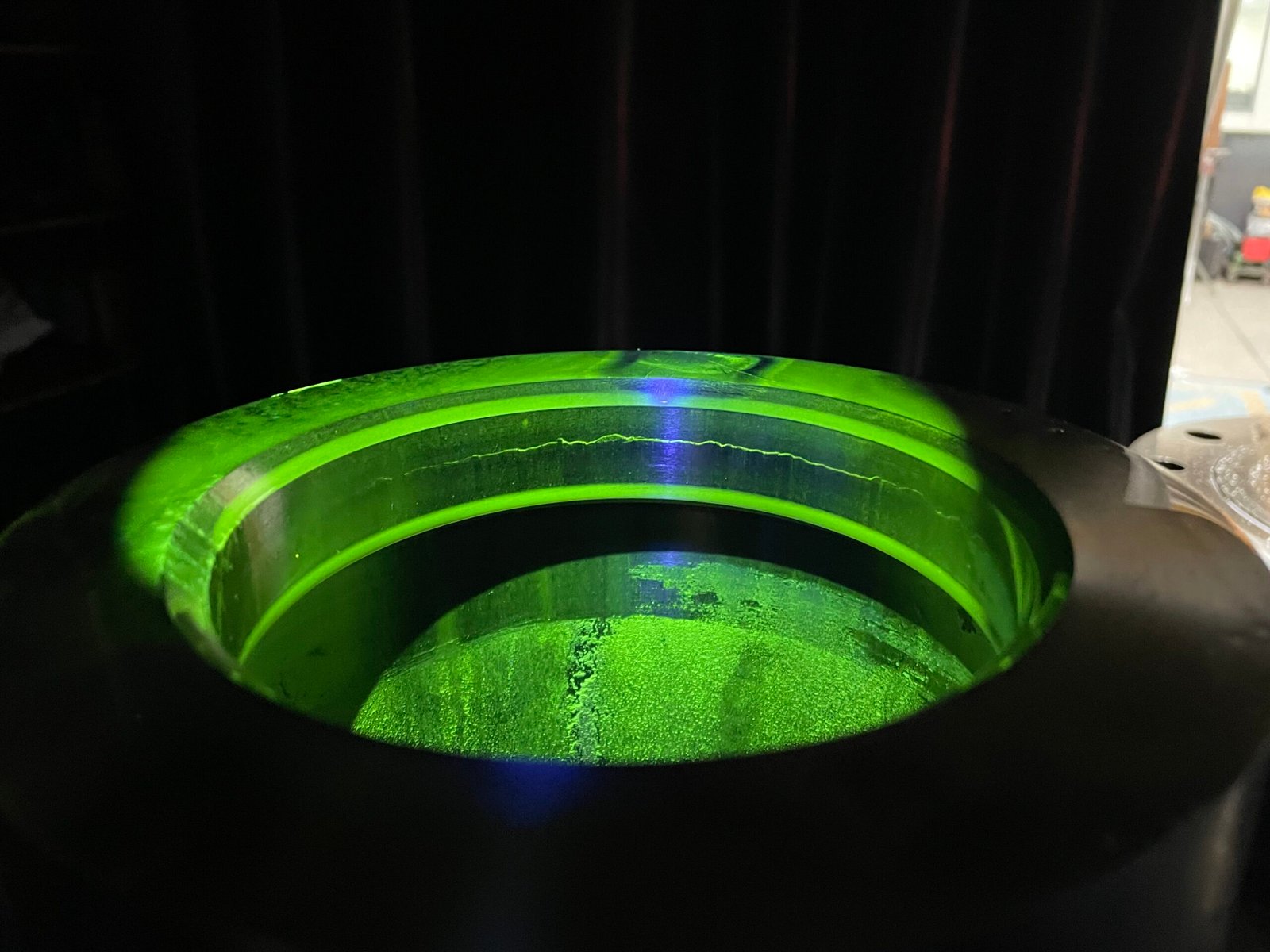

NII can replace internal entry only when you can prove the selected techniques will find the expected damage with adequate coverage and sensitivity. Typical patterns:

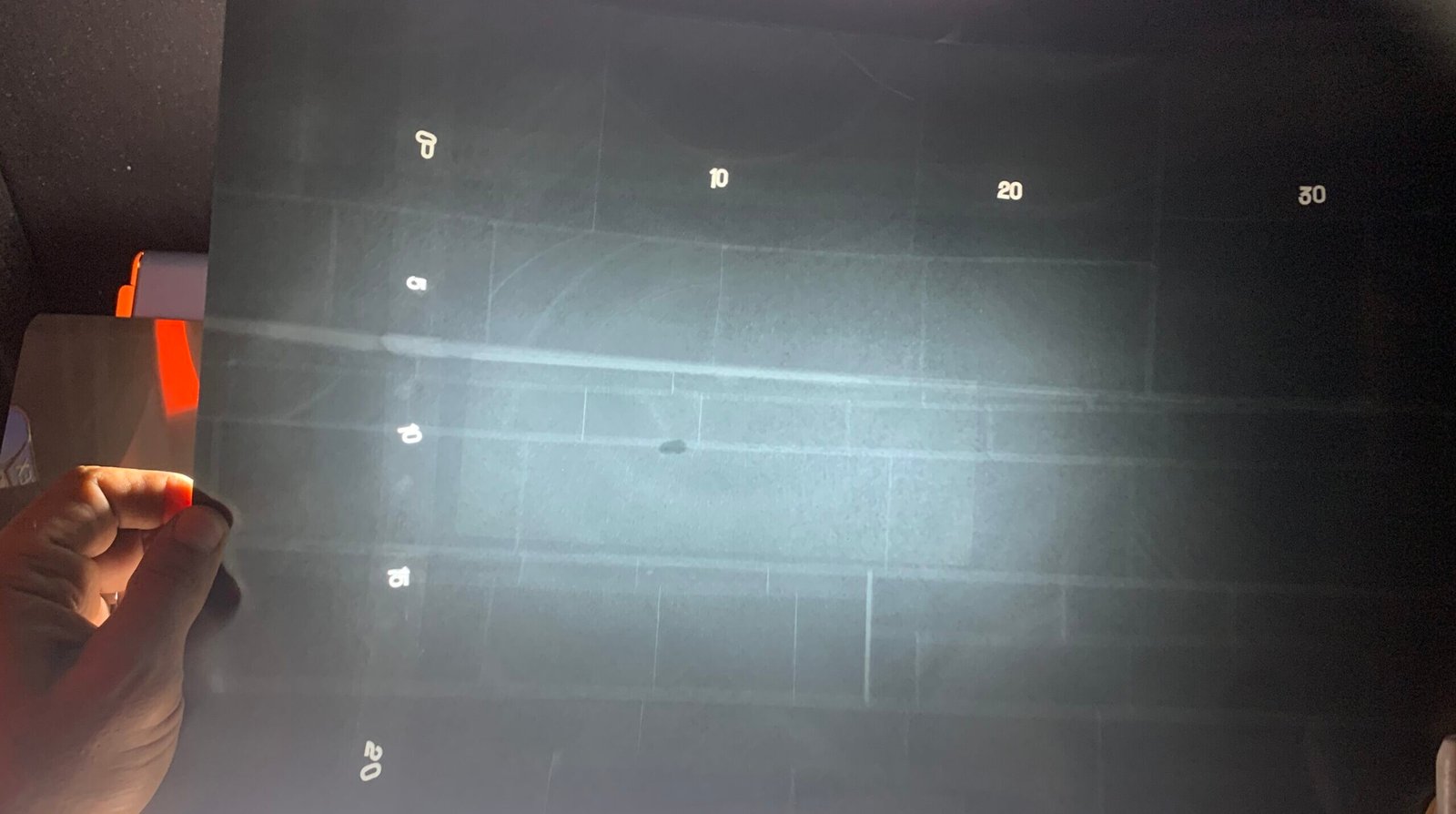

Pressure vessels with CUI risk: remove inspection bands at low points, supports and water traps; use VT + UT/PAUT; consider profile RT in localised areas.

Exchangers: UT grids on shells and nozzles; eddy current/RFT for tube inspection; PAUT at tube-tubesheet and nozzle blend radii.

Sour service (HIC/SOHIC risk): shear-wave UT/PAUT, hardness/replication where appropriate.

Key point: NII by itself doesn’t justify extended intervals. It’s a technique choice, not a free pass. Show your coverage and PoD (probability of detection) logic.

“Boilers, receivers, piping—each ages differently. AS 3788 gives you a plan that keeps up: risk-based intervals, targeted NDT, audit-ready records.”

Damage mechanisms → where to look → what to use

| Damage mechanism | Likely hotspots | Effective methods |

|---|---|---|

| General corrosion | Shells, heads, low points, dead legs | UT spot/grid; corrosion rate trending |

| Pitting / under-deposit | Exchanger shells & tube sheets, low-velocity areas | UT grid, pit gauges; eddy current/RFT for tubes |

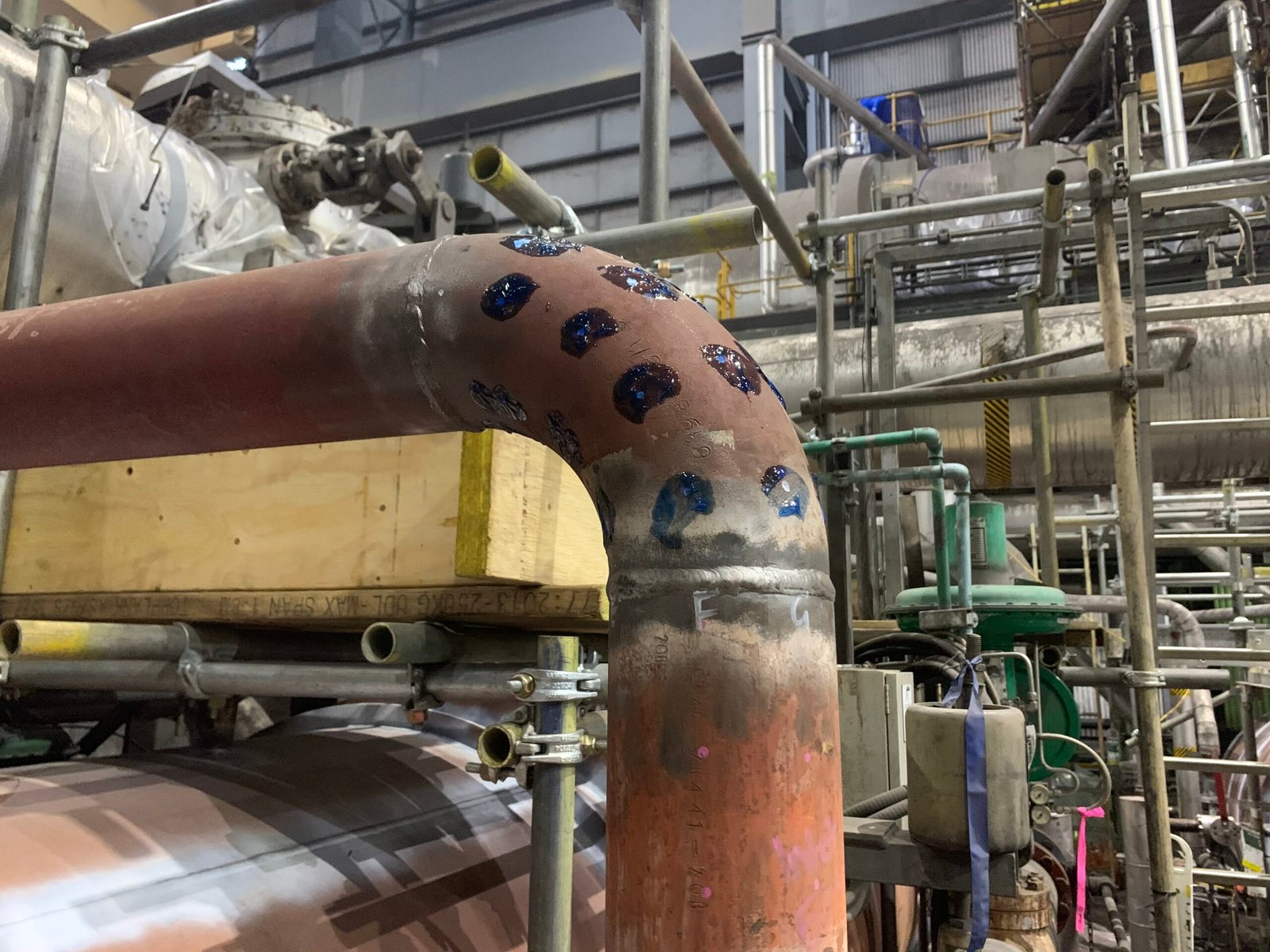

| CUI (corrosion under insulation) | Insulation terminations, supports, low points, penetrations | Strip bands + VT, UT/PAUT; profile RT where justified |

| Erosion-corrosion | Elbows, reducers, tees, control valve outlets | UT trending; PAUT at thinning regions |

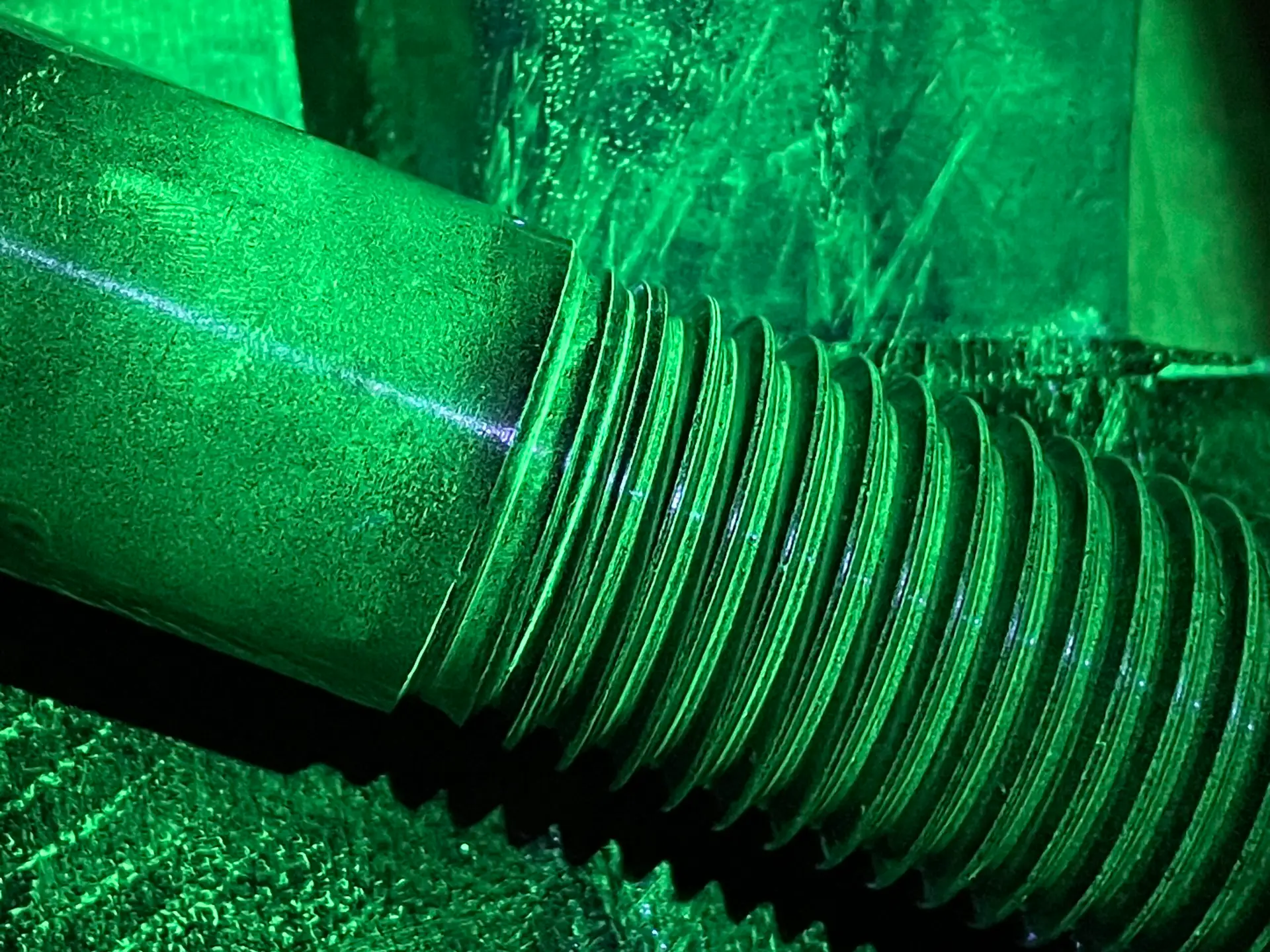

| SCC (chloride/caustic etc.) | Weld toes, HAZ; hot/wet areas | PT/MT for surface; PAUT/TOFD for subsurface |

| HIC/SOHIC (sour) | Mid-wall in susceptible steels | Shear-wave UT/PAUT; hardness/replication |

| Fatigue / thermal cycling | Nozzles, attachments, supports | VT with magnification; PAUT at fillet/attachment welds |

| Creep (high temp) | Long-service shells, headers | Replication, hardness, deformation surveys |

PSV/relief device management that stands up in audits

Your relief system is the last line of defence. Keep it boring (and compliant):

Traceability: Each PSV/PRV tag must map to the protected equipment, set pressure and service.

Certification: Maintain current pop/bench-test evidence; log set pressure, lift and seat tightness (as-found vs as-left).

Valve status: Ensure no blocked relief paths. Any isolation must follow a strict, documented protocol.

Change control: Re-assess whenever process conditions or relieving scenarios change.

Piping circuits: smart coverage without blowing the budget

Piping is often the largest risk surface and the hardest to manage. Streamline with:

Circuits by corrosion environment (not only by line number).

CMLs/TMLs at elbows, reducers, low points and known water traps; include small-bore connections and dead legs.

Screening first (guided wave or screening UT on long runs), then target with A-scan UT.

Update isos when repairs and replacements occur; stale drawings = missed hotspots.

Building an audit-ready inspection plan (step-by-step)

1) Equipment register

Unique ID, description, location, fluid, design code, MAWP/temperature, corrosion allowance, hazard level (AS 4343), registration status.

2) Strategy and rationale

TBI or RBI and why; expected damage mechanisms by component; operating envelope and excursions that matter.

3) Scope by inspection type

External/operational: leaks, noise/vibration, hotspots, supports/clips, drains/low points, insulation/coating, nameplates/markings.

Close-up: detailed VT for nozzles, attachments, saddles, small bore branches.

Internal (if opened): shells/heads, internals (trays, baffles, demisters), nozzles, weld seams, deposits/erosion.

NDT & tests: method, coverage (grids, CMLs), acceptance criteria, and reporting format.

PSVs/PRVs: interval, set pressure, leakage acceptance, tagging and cert retention.

4) Access and preparation

Isolation/spading, cleaning/neutralisation, gas tests, scaffolding/rope access, lifting points, confined space permits, insulation removal bands.

5) Evaluation & acceptance

Minimum wall calculations and remaining life formula, crack acceptance by method, deformation limits, FFS decision tree.

6) Reporting & records

Standardised report with photos, UT tables, as-found/as-left condition; recommendations with priorities and due dates; revision control and storage path.

Common Issues, Risks & What to Watch Out For

Hidden fatigue cracks in welds or high-stress zones

Bolt loosening or fatigue failure (especially in tension joints)

Severely corroded or pitted structural steel

Excessive wear internal to gearboxes or bearings (hard to detect without opening)

Wire rope core damage or broken strands not visible externally

Misalignment, binding, bearing play

Failed or inaccurate load-limiting devices or indicators

Electrical insulation degradation or connections loosening

Hydraulic leaks, seal failures under stress

Poor previous repair work or patches

Inadequate rectification of earlier defects

Underestimating downtime and logistical complexity

Boilers, air receivers, pressure vessels, heat exchangers, piping systems and their relief devices once they’re in service.

Hazard level (AS 4343) informs registration and helps set inspection depth/frequency. For QLD compliance, it’s a key input.

Yes—if it’s documented, uses competent people and yields intervals/scopes proportionate to risk.

Plan an early in-service confirmation (often around the first year) to validate assumptions and set a justified ongoing interval.

Sometimes. Record stable conditions, risk controls and any interim checks. Keep deferrals short and traceable.

Yes, when you can prove adequate coverage and sensitivity for the specific damage expected. It’s not a blanket substitute.

Enough to trend where damage is most likely (drains, low points, elbows, control valve outlets). Start with grids; refine with data.

No. It depends on the repair type, code/design basis and your plan. Targeted NDT may be more appropriate

Trend shell UT and tube NDT (eddy current/RFT). Open when risk/cleaning requires it or data shows deterioration.

Create a template per type; customise only for unusual service or history.

No. Cracking, erosion and localised attack may need PAUT/TOFD, MT/PT or radiography.

Tag, protected equipment, set pressure, as-found/as-left data, seat leakage result, tester, date, and next due date.