10-Yearly Crane Testing in Australia: Using Eddy Current and Magnetic Particle Inspection

Cranes are critical assets in industrial, marine, and construction environments. In Australia, strict safety regulations require that all cranes undergo comprehensive 10-yearly inspections to ensure operational integrity and compliance with standards such as AS 2550 (Cranes, Hoists and Winches).

Beyond visual inspection and load testing, advanced non-destructive testing (NDT) methods such as Eddy Current Testing (ECT) and Magnetic Particle Inspection (MPI) are increasingly used to support these inspections. These techniques help detect cracks, fatigue, and corrosion that could compromise crane safety and reliability.

Why 10-Yearly Crane Testing Is Critical

While daily and annual inspections are essential, the 10-yearly inspection is more comprehensive, designed to evaluate the crane’s structural and mechanical integrity over its lifespan.

During this inspection, engineers assess:

Weld quality and integrity

Structural fatigue in booms, jibs, and supporting frameworks

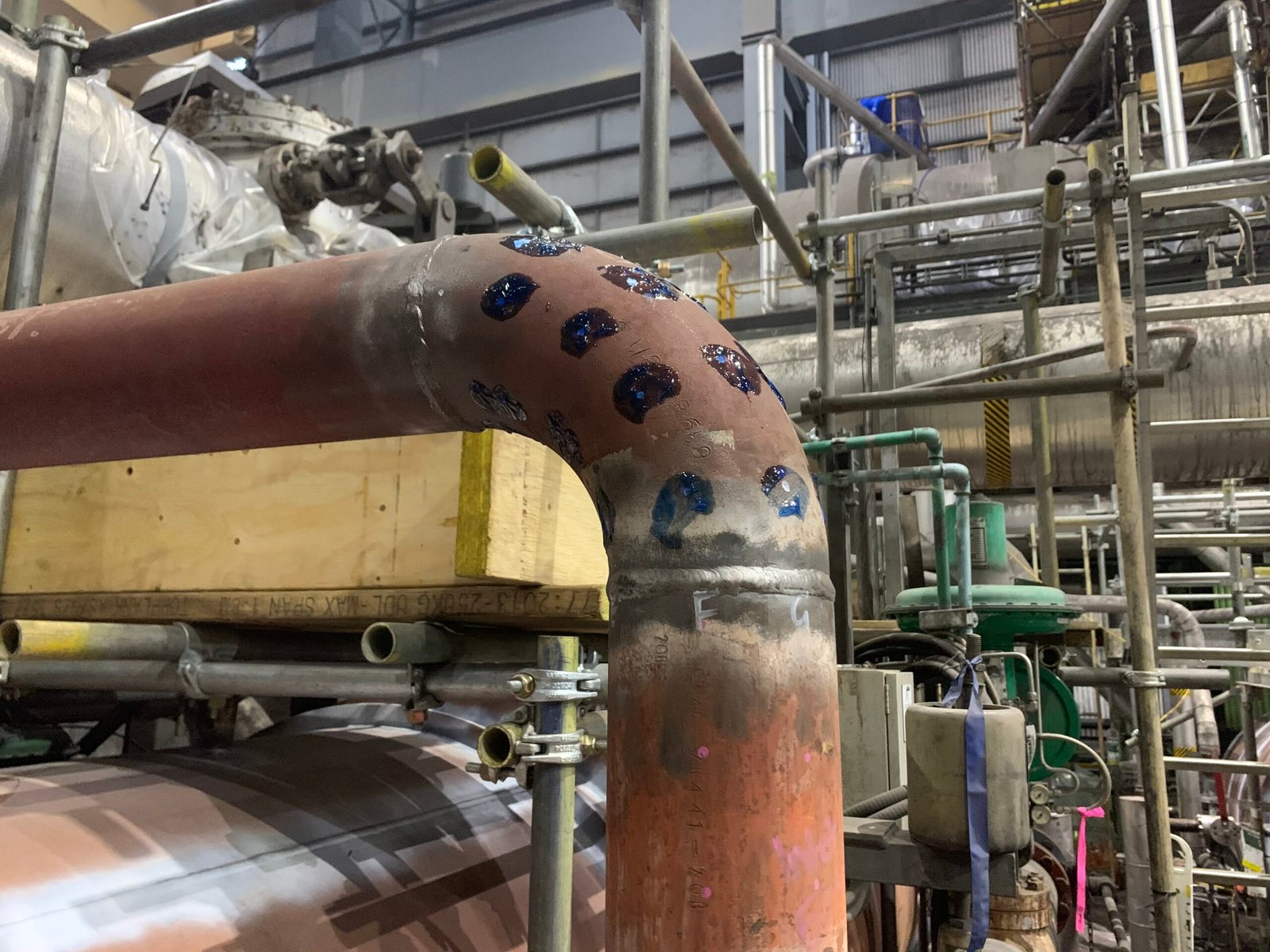

Corrosion or surface defects

Mechanical components such as ropes, hooks, and sheaves

Moreover, regulators require detailed documentation of any defects found, corrective actions taken, and verification that the crane is safe for continued operation.

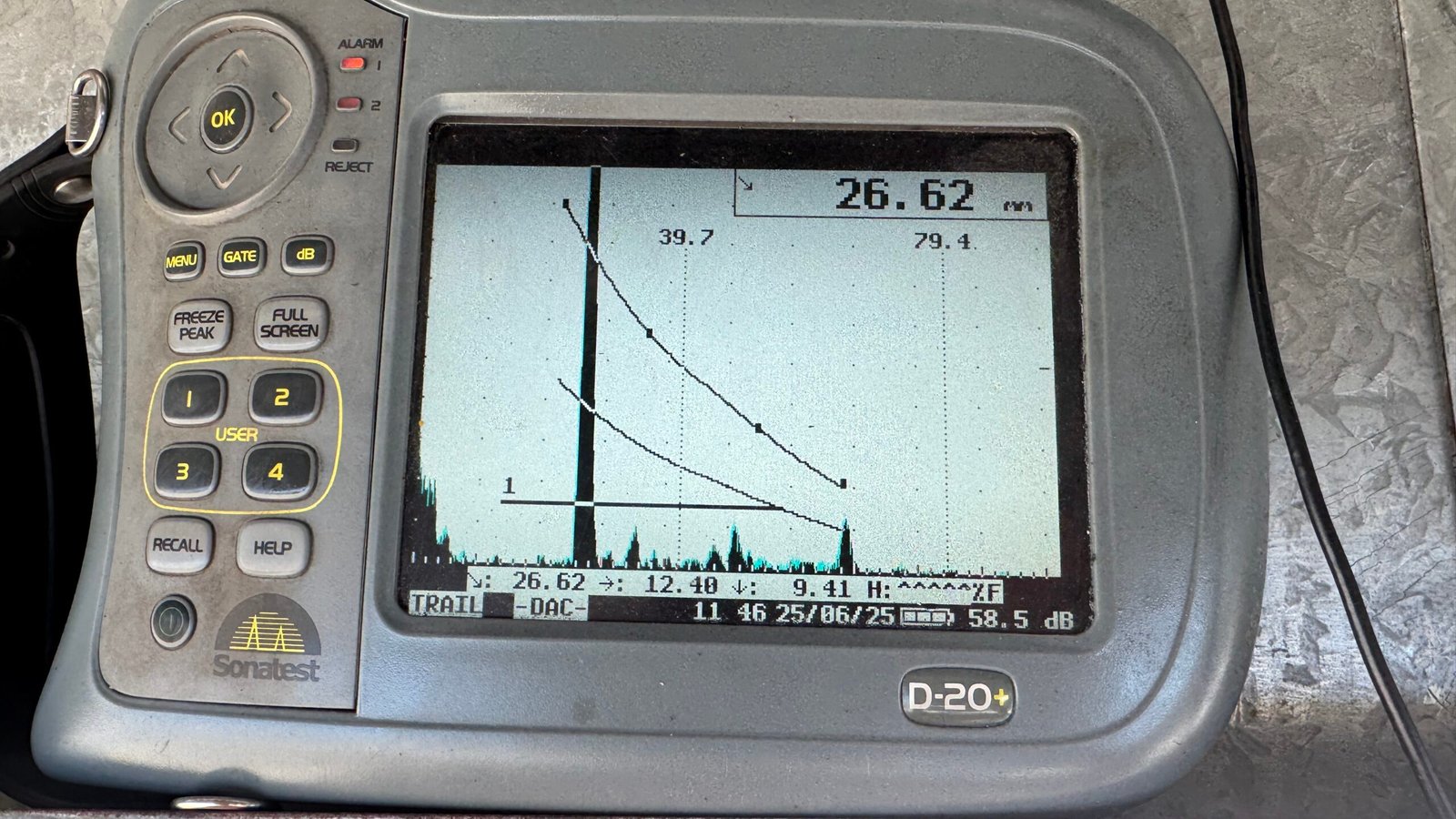

Eddy Current Testing (ECT) for Crane Components

Eddy Current Testing is a non-contact NDT method used to detect surface and near-surface cracks in conductive materials such as steel.

How ECT Works:

A probe generates an electromagnetic field, inducing eddy currents in the material.

Any discontinuity, crack, or corrosion changes the eddy current flow.

The device records these changes, allowing technicians to detect defects that are not visible to the naked eye.

Why ECT Is Used for Cranes:

Detects small cracks in critical components like crane hooks, wire ropes, and booms.

Fast, accurate, and can inspect complex geometries without disassembly.

Supports predictive maintenance, reducing the risk of unexpected failure.

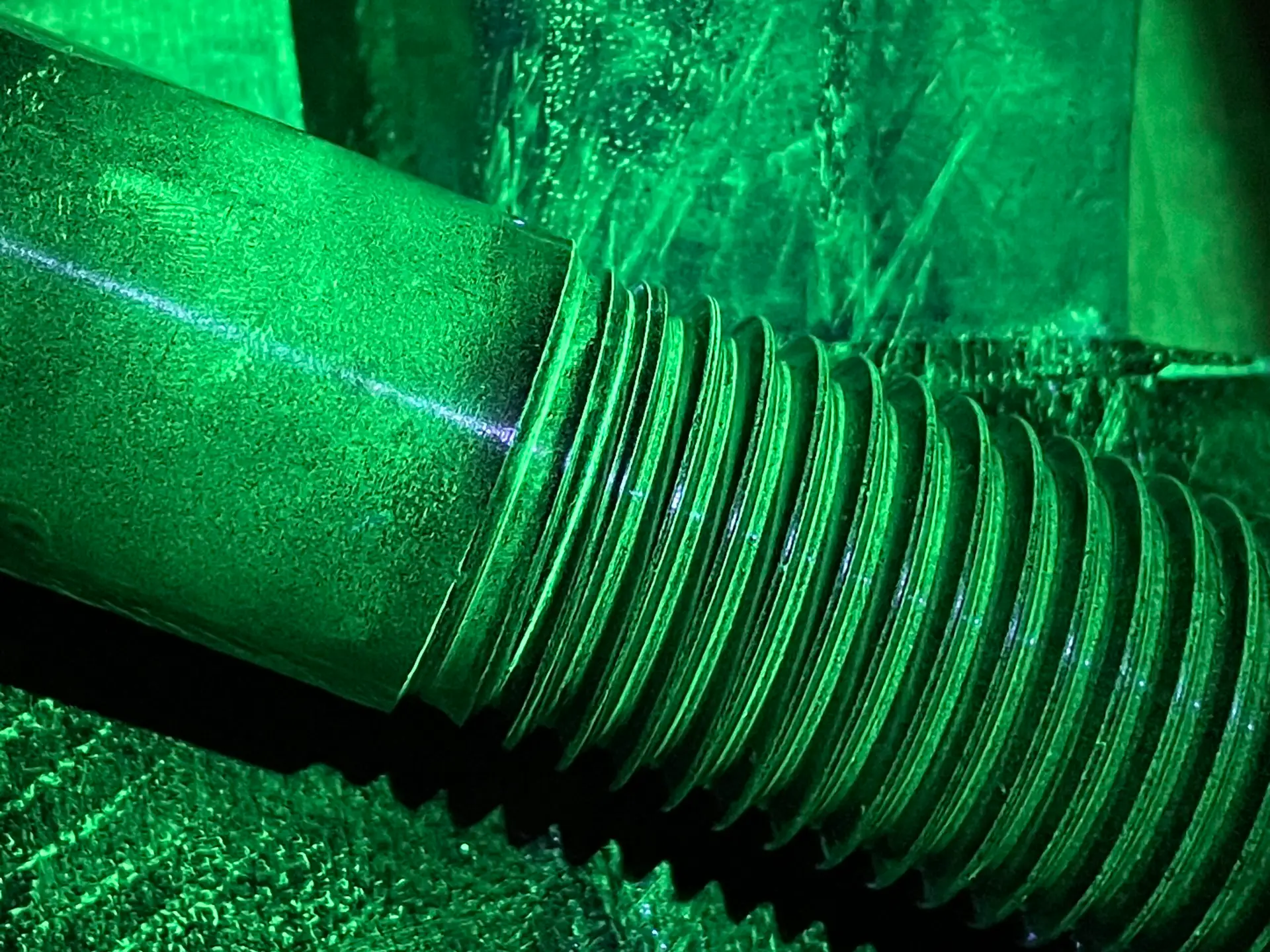

Magnetic Particle Inspection (MPI) for Crane Safety

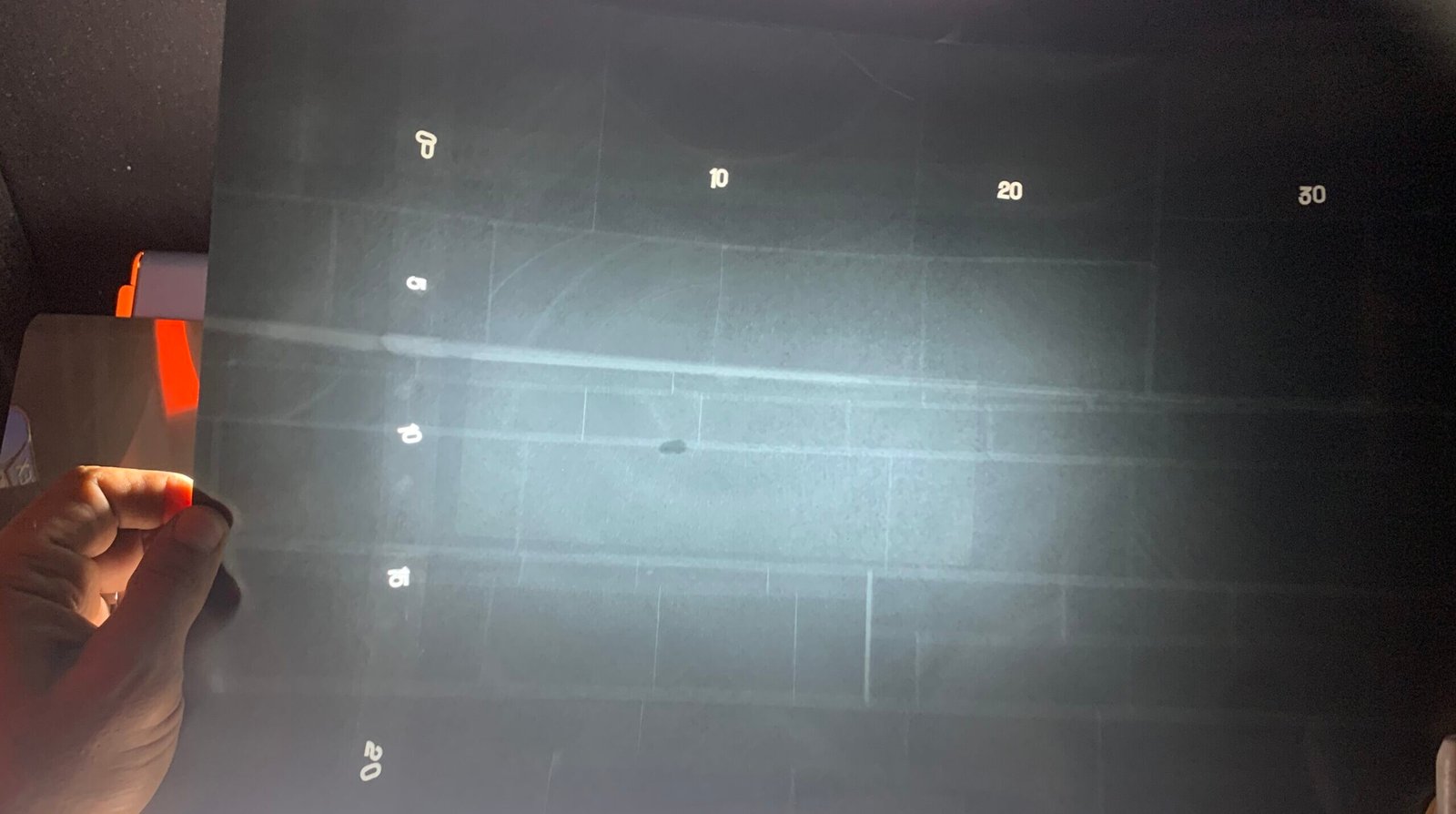

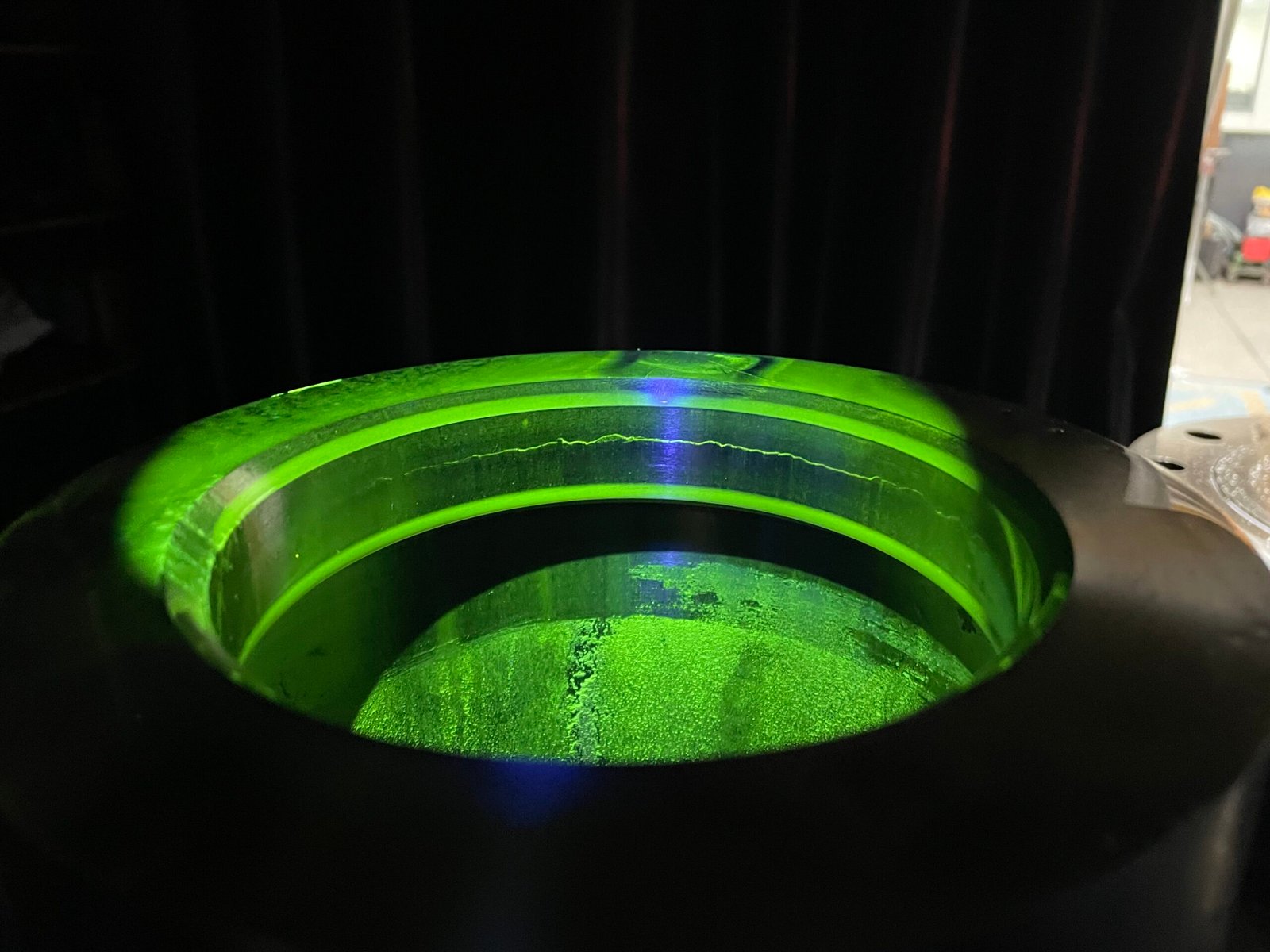

Magnetic Particle Inspection is a widely used method for detecting surface and near-surface cracks in ferromagnetic materials.

How MPI Works:

The component is magnetized using an electric or permanent magnet.

Fine magnetic particles (dry or wet) are applied to the surface.

Cracks or defects disrupt the magnetic field, causing particles to gather and highlight the flaw.

Benefits of MPI in Crane Inspections:

Detects surface cracks in welds, structural joints, and critical stress points.

Ideal for crane booms, welds, and load-bearing components.

Provides clear, visual indications of defects for reporting and certification.

Integrating ECT and MPI into the 10-Yearly Inspection

While a standard 10-yearly crane inspection includes load testing and visual checks, ECT and MPI provide additional confidence:

ECT is ideal for detecting fatigue cracks in conductive materials that are not visible externally.

MPI excels at inspecting welds and high-stress points in ferromagnetic components.

Together, these NDT methods ensure that the crane is structurally sound and safe to operate, meeting both regulatory and operational standards.

Furthermore, combining these inspections with detailed documentation supports certification and compliance, which is essential for audits and insurance requirements.

“Visual inspections alone can miss fatigue cracks or surface defects in cranes. Eddy Current and Magnetic Particle Testing provide precise detection, ensuring safe, certified operation.”

Why Choose Professional NDT for Crane Inspections

Partnering with an experienced NDT provider ensures:

Compliance with Australian safety standards and regulations.

Comprehensive detection of surface and subsurface defects.

Reliable certification that meets insurance and regulatory requirements.

Reduced downtime through accurate assessment and predictive maintenance.

At Qualiss, we provide Eddy Current Testing, Magnetic Particle Inspection, and full 10-yearly crane inspection services across Australia, supporting businesses in maintaining safe, compliant, and reliable crane operations.

Why Choose Professional NDT for Crane Inspections

Partnering with an experienced NDT provider ensures:

Compliance with Australian safety standards and regulations.

Comprehensive detection of surface and subsurface defects.

Reliable certification that meets insurance and regulatory requirements.

Reduced downtime through accurate assessment and predictive maintenance.

At Qualiss, we provide Eddy Current Testing, Magnetic Particle Inspection, and full 10-yearly crane inspection services across Australia, supporting businesses in maintaining safe, compliant, and reliable crane operations.

A 10-yearly crane inspection is a comprehensive evaluation of a crane’s structural and mechanical integrity. It goes beyond routine checks to include detailed inspections, load testing, and non-destructive testing (NDT) methods to ensure compliance with Australian standards such as AS 2550.

ECT and MPI detect surface and near-surface defects, fatigue cracks, and corrosion that visual inspections alone might miss. These methods provide precise, actionable data that support the safety, reliability, and certification of cranes.

Critical load-bearing components such as crane hooks, booms, jibs, wire ropes, welds, and structural joints are typically inspected using ECT and MPI to identify cracks, corrosion, and other defects.

As the name suggests, these inspections are required every 10 years for cranes in Australia. They complement daily, weekly, and annual inspections to ensure long-term operational safety and compliance.

Yes. Once a defect is identified, engineers can assess whether repairs or reinforcements are required. Corrective actions are documented to maintain compliance and certification for continued safe operation.

Qualified NDT professionals with experience in ECT, MPI, and crane inspection should conduct these tests. Using certified technicians ensures accurate detection, proper documentation, and compliance with Australian regulations.

Absolutely. All inspections are accompanied by detailed reporting and certification to verify that the crane meets safety and regulatory standards.