Introduction

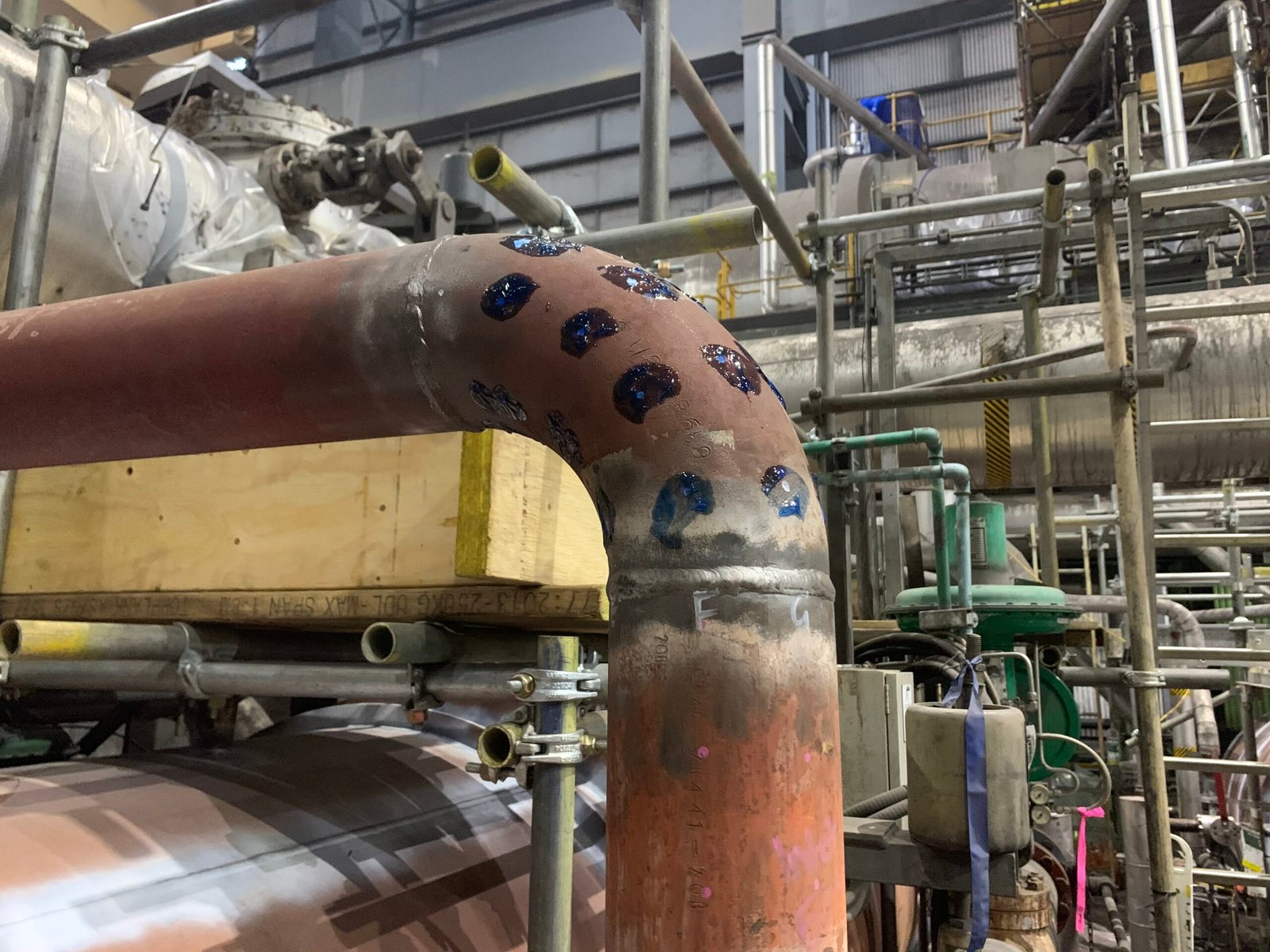

During a scheduled 10 Yearly Boom Inspection, the crane boom was removed by the maintenance contractor and made ready for testing.

Once it was on the ground, Qualiss carried out magnetic and visual testing on every weld, lug, and high-stress joint.

Using a black-and-white wet MPI method, our inspectors found several fine cracks along weld toes and lug connections — common fatigue points on busy cranes.

Each crack was marked, repaired, and re-tested to confirm the boom’s strength and safety before re-certification.

Why 10-Yearly Boom Inspections Matter

According to AS 2550.5 and AS 1418, all truck and mobile cranes need a major inspection every 10 years.

The process includes removing, cleaning, and checking the boom for rust, warping, or cracks.

Over years of lifting, heat, and vibration, small fatigue cracks can form at welds and attachment points.

Early inspection helps prevent costly breakdowns and ensures every crane stays safe and compliant with Australian Standards.

Step 1 — Visual Inspection (VT)

Initial Check

First, our inspectors examined each weld under bright light.

They looked for:

Paint cracks or lines around weld toes and gusset plates

Wear or movement near pins and bushings

Heat tint, rust, or distortion around joints

Next, they cleaned and marked any areas that needed closer attention.

Visual inspection gives the first clue — showing where to focus deeper testing.

Field Observations

In addition, we saw minor corrosion and small surface marks that could grow into cracks if ignored.

By spotting these early, the team prevented future damage and saved the client both time and repair costs.

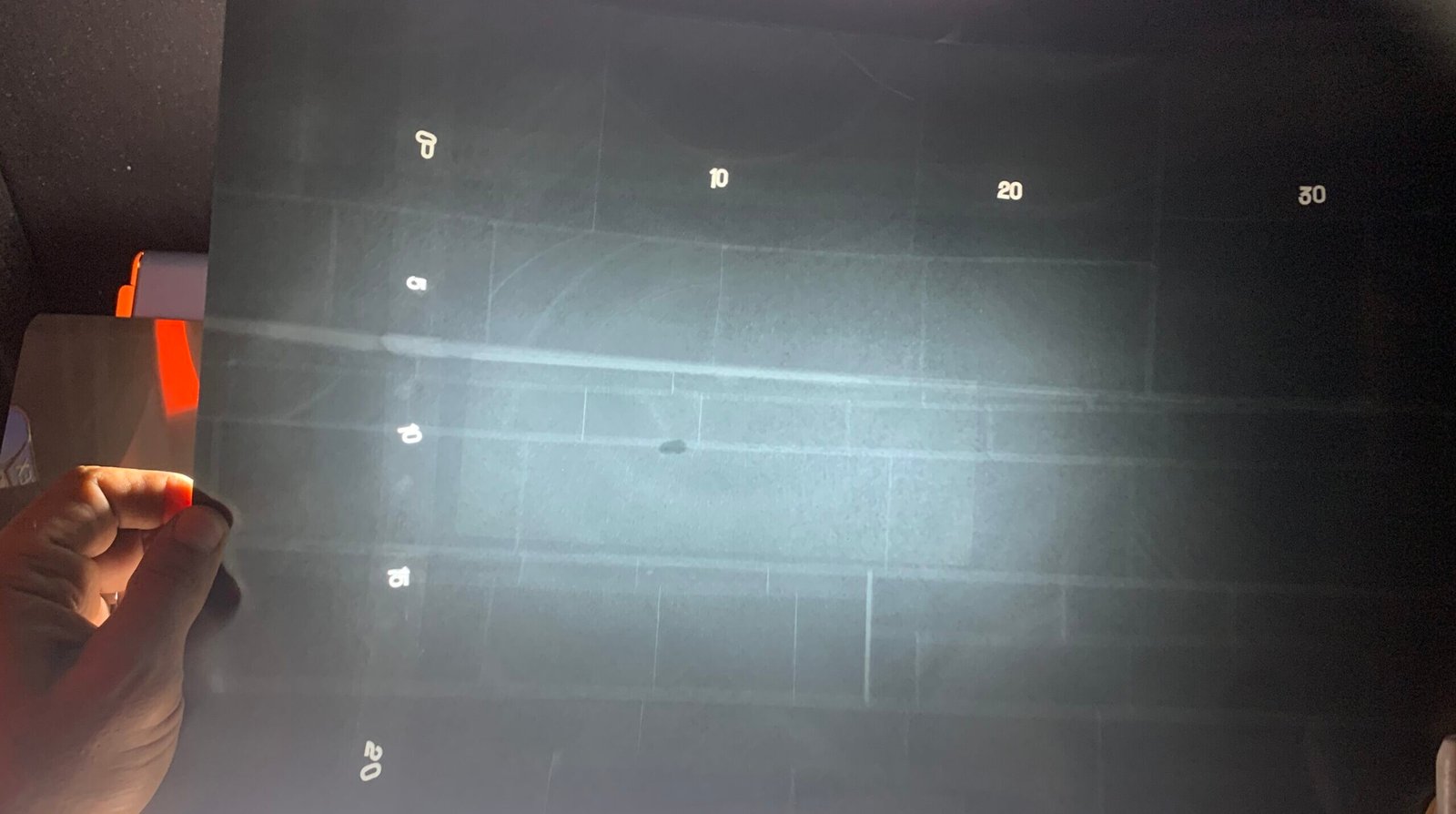

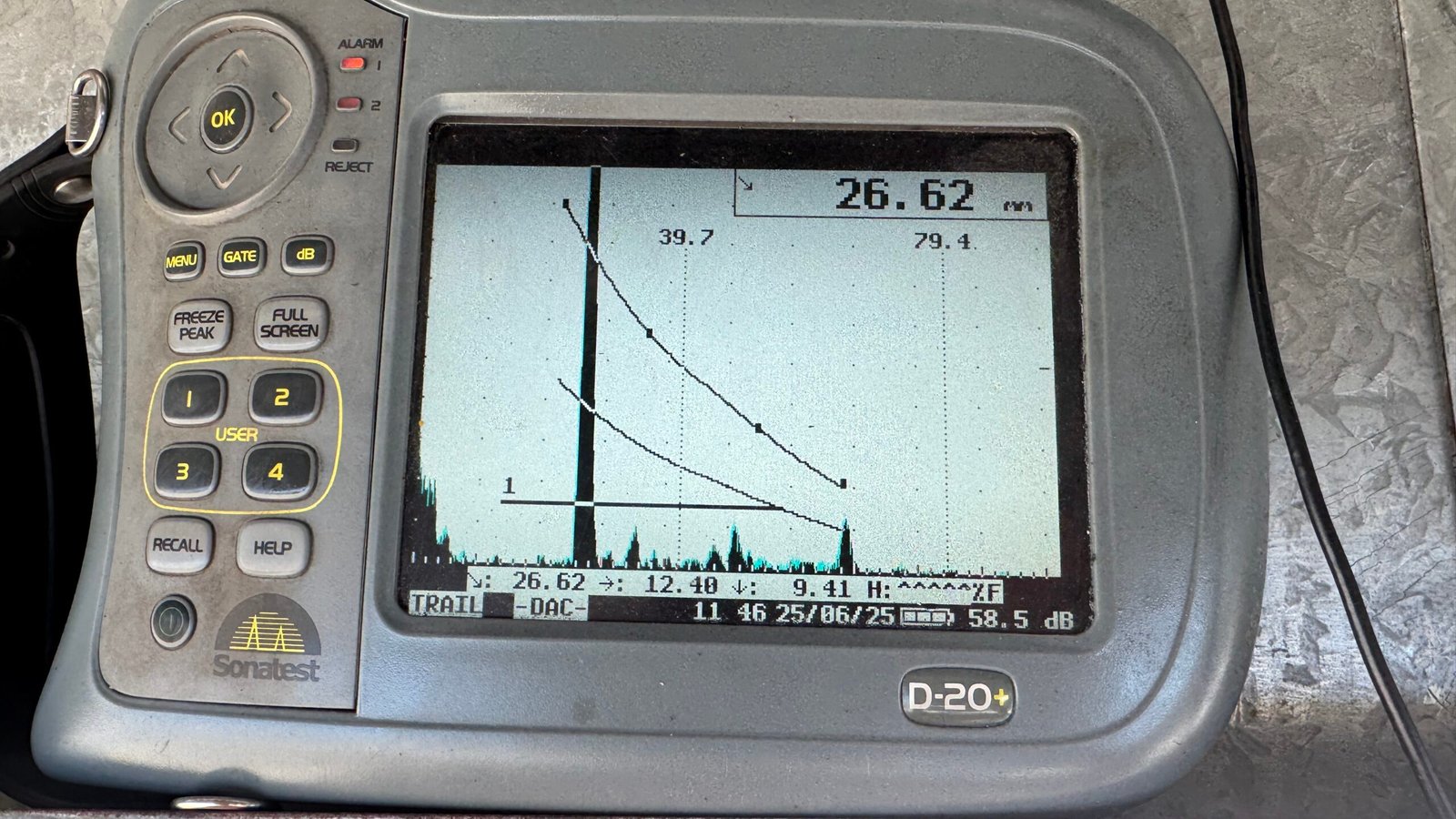

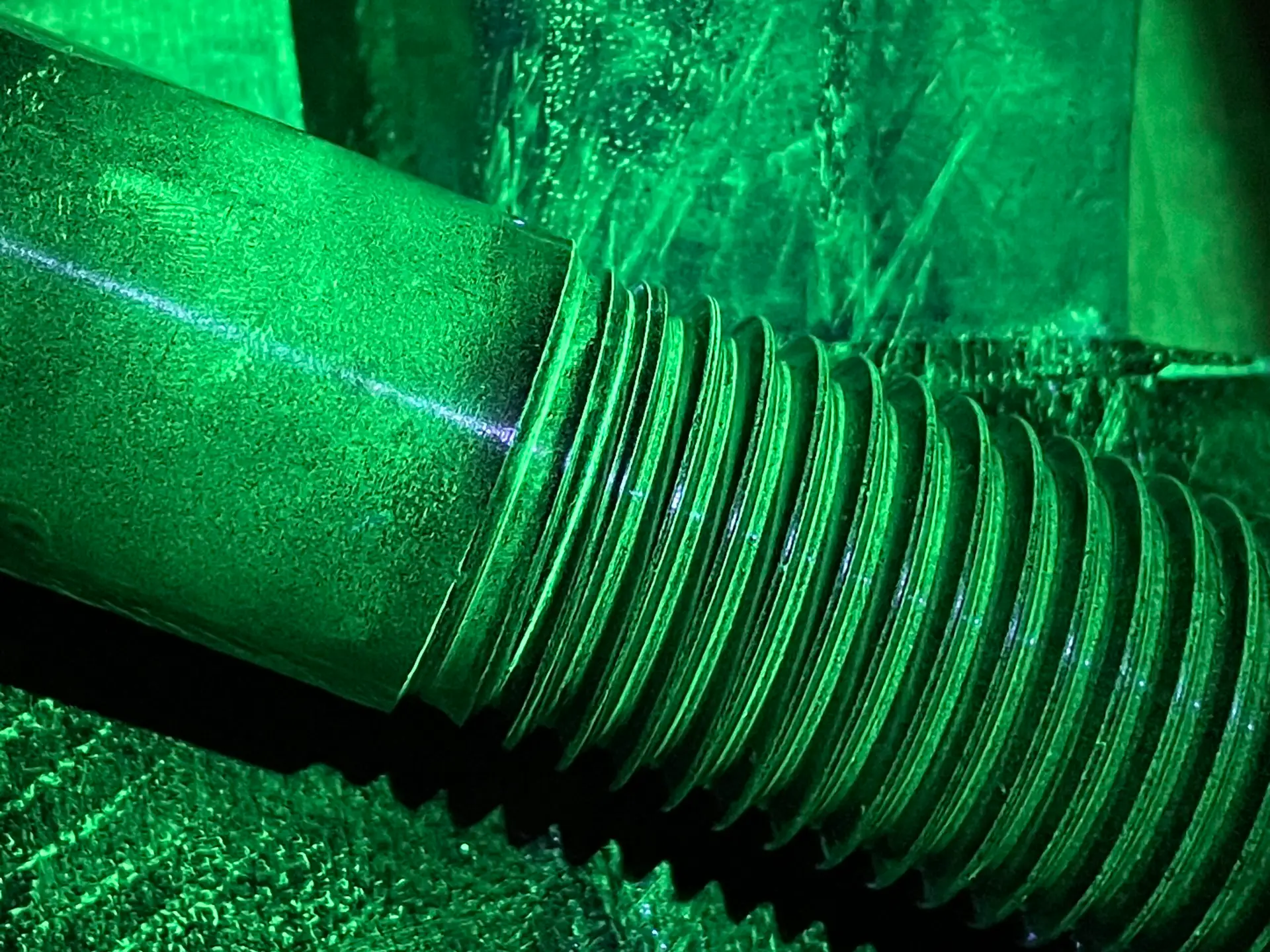

Step 2 — Magnetic Particle Inspection (MPI)

Preparation and Testing Process

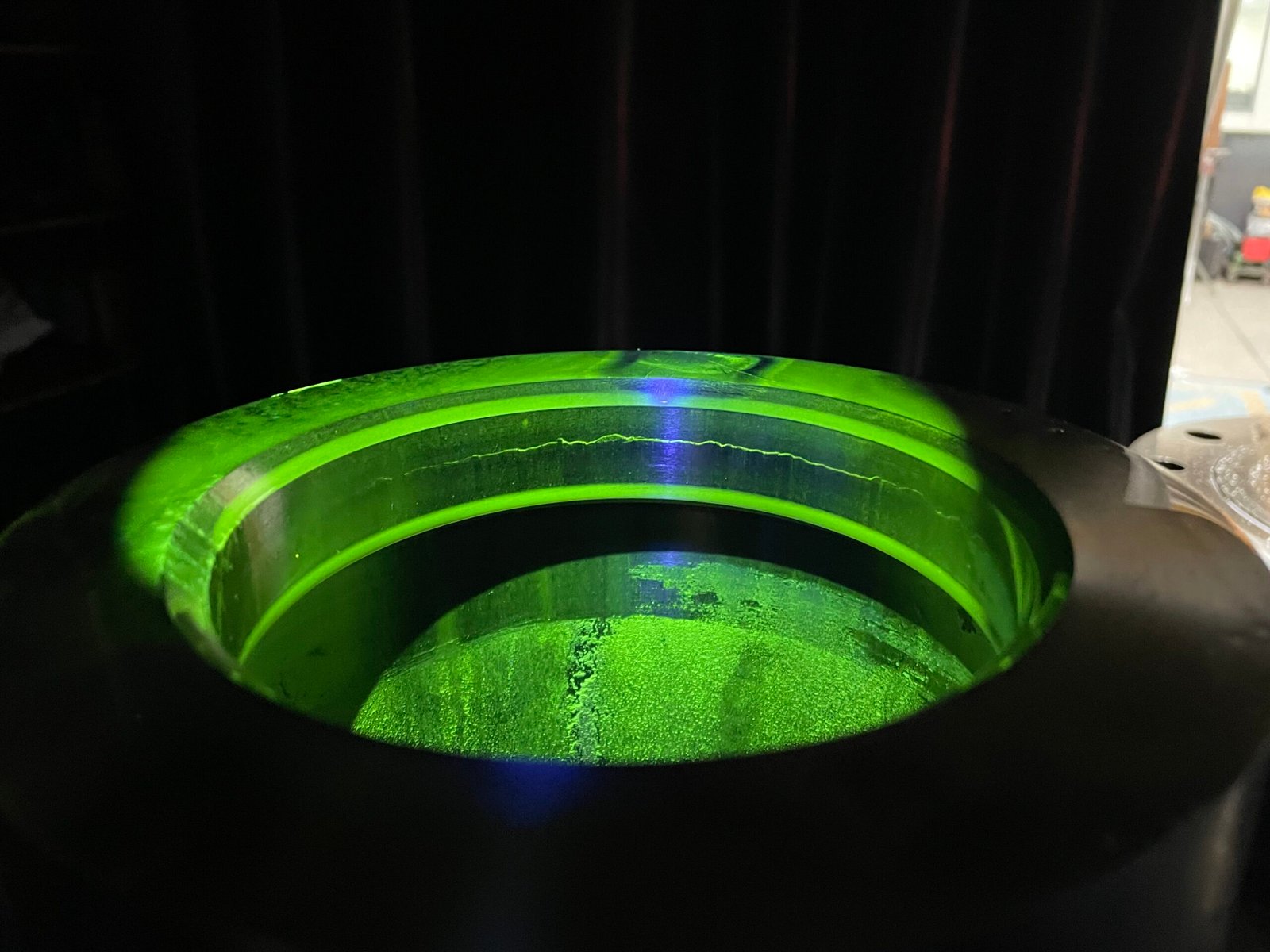

After cleaning, the technicians coated each weld with a thin white background paint.

Next, they sprayed a black magnetic ink suspension across the surface and used an AC yoke to magnetise the steel.

As a result, magnetic particles gathered wherever a crack interrupted the field.

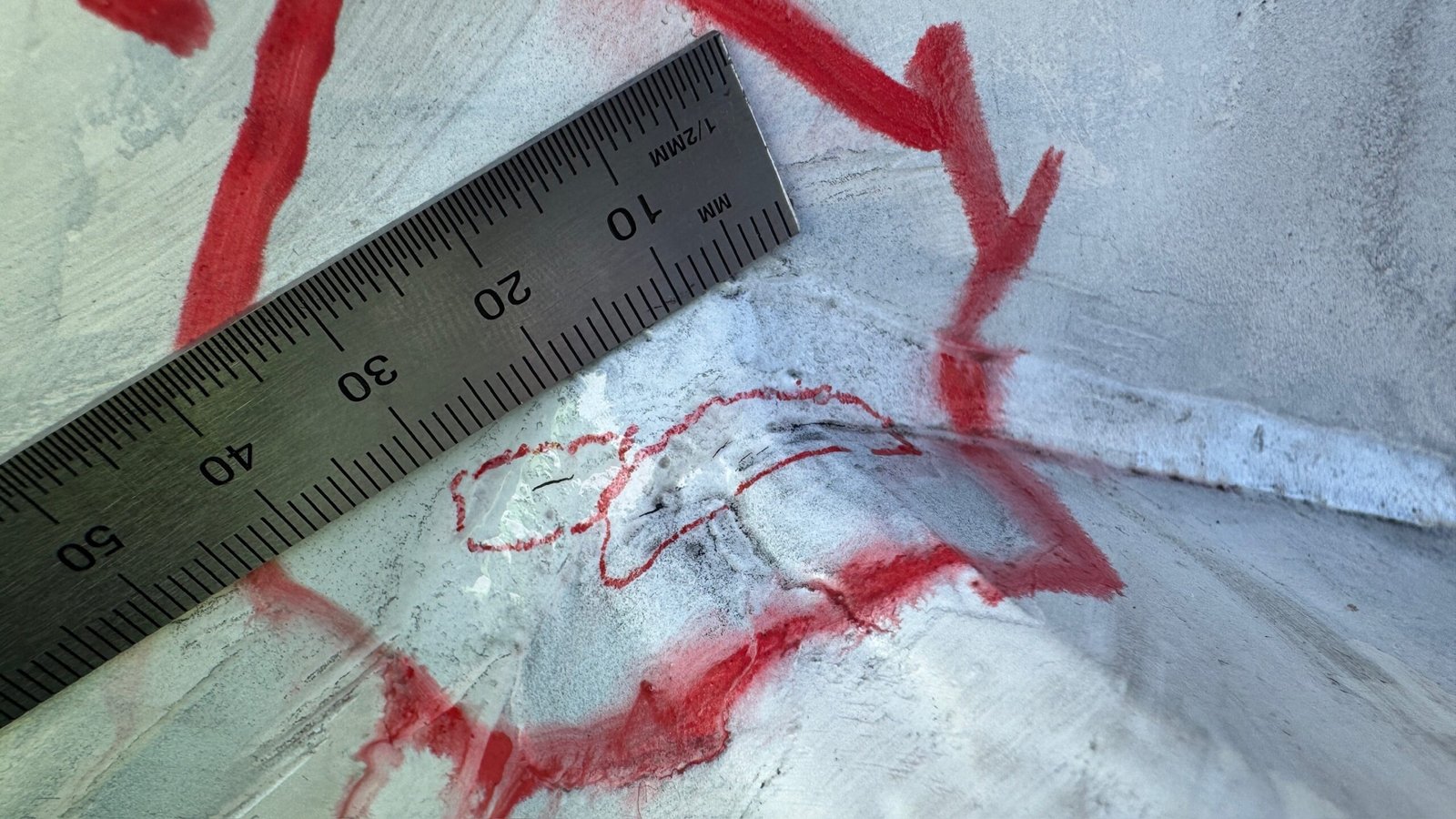

Fine lines appeared on weld toes and lug joints, showing several small fatigue cracks that could not be seen with the naked eye.

Field Testing Observations

Our team marked and measured each indication immediately.

They took photos, logged the crack length and direction, and compared results with past inspection data.

In addition, we checked which defects were larger than the limit set by Australian Standards.

When a weld needed repair, we stopped testing, called in the repair contractor, and supervised the weld work directly.

Crack Mapping and Repair Verification

Afterward, our inspectors re-tested all repaired spots using the same black-and-white wet MPI method.

Consequently, no cracks remained, confirming that the welds were sound.

Finally, the team confirmed that the boom met the required safety standards before re-installation and re-certification.

Step 3 — Reporting and Compliance

Documentation and Verification

After testing, Qualiss prepared a clear report with photos, crack maps, repair notes, and calibration records.

Each weld, pin, and lug was listed so the client could prove the boom met Australian Safety Standards.

Therefore, the inspection record was complete and easy to follow.

In addition, our team reviewed the report before release to make sure every result matched the site data.

This extra step kept the quality high and gave the client peace of mind for insurance and audits.

Inspection Record Management

To make record-keeping simple, we grouped all photos and technician notes by boom section.

Afterward, we delivered a digital copy to the client and explained the results in plain language.

Finally, the crane owner received a full report package that supports future audits, re-certification, and long-term safety tracking.

“Crane booms lift without complaint—until a hairline crack finds its voice. Regular inspection turns hidden stress into certainty and safety.”

Book a Certified Boom Inspection

Qualiss provides certified Magnetic Particle, Ultrasonic, and Visual Testing for cranes and lifting equipment across Queensland.

Our technicians are qualified to AS ISO 9712 and follow NATA-aligned procedures, ensuring every inspection meets Australian Standards.

📞 Contact us to schedule your next 10 Yearly Boom Inspection, or explore our complementary services:

Key Takeaways

10 Yearly Boom Inspections detect fatigue cracks before failure occurs.

Visual Testing identifies early signs of corrosion and distortion.

Black-and-white wet MPI reveals surface cracks with excellent contrast.

Proper repair and re-testing restore compliance and extend boom life.

Comprehensive documentation supports insurance, audit, and regulatory needs.

A 10 Yearly Boom Inspection involves removing the boom, cleaning all welds and joints, and performing Visual and Magnetic Particle Testing to identify cracks, corrosion, or distortion. Any defects are repaired, re-tested, and documented before the crane returns to service.

Magnetic Particle Inspection (MPI) detects surface-breaking or near-surface cracks that may not be visible during routine checks. Using a black-and-white wet method provides strong contrast under daylight, making it ideal for steel booms and high-stress weld zones.

Cracks usually appear at weld toes, lug welds, and pin connection points, where cyclic loading concentrates stress. Fatigue, vibration, and corrosion all contribute. These small cracks can grow quickly if not caught during the 10-yearly inspection cycle.

Major inspections follow AS 2550.5 Cranes – Safe Use and AS 1418 Cranes – Design and Construction, with NDT work performed by technicians certified to AS ISO 9712. Compliance ensures structural integrity, legal assurance, and insurance acceptance.

When indications appear during MPI, they are measured, photographed, and evaluated. Repairs follow OEM or code-approved welding procedures, and the same areas are re-tested after repair to confirm that the crack has been completely removed.

Duration depends on boom size and findings, but most truck cranes require two to four days from removal to re-testing. Planning for cleaning, NDT, repairs, and documentation avoids extended downtime.

Qualiss combines certified AS ISO 9712 inspectors, excellent reporting, and full-traceability documentation. Our process ensures every 10 Yearly Boom Inspection meets compliance, reduces risk, and keeps your crane safe and operational for the next decade.