Introduction: Why 10-Year Crane Inspections Are Critical

Every crane, whether overhead, gantry, mobile or tower, operates under heavy mechanical stress, variable loads, environmental exposure, and fatigue cycles. Over time, even with daily maintenance and yearly inspections, hidden defects can develop in structural components, welds, bolts, or internal assemblies.

A 10-year major inspection (also called a “major overhaul” or “strip-down inspection”) is the deep, forensic level check that ensures the crane is still safe, reliable, and legally compliant for continued service. Skipping it or doing it halfheartedly can lead to catastrophic failures, regulatory penalties, insurance voidance, injured workers, and costly downtime.

In Australia, under Work Health & Safety (WHS) laws and the WHS General Regulations, the person with management or control of registered mobile or tower cranes must ensure a major inspection is done at the end of the design life, or if no design life is given, every 10 years from first commissioning or registration — whichever comes first. worksafe.wa.gov.au

This guide will walk you through what the 10-year inspection should include, how to prepare, what to watch out for, and how to make sure you’re compliant and safe.

Legal and Standards Context in Australia

WHS Regulation 2011 (Qld) — Regulation 235 “Major inspection of registered mobile cranes and tower cranes”

This is the specific QLD regulation requiring a major inspection at the end of design life or, if no design life, every 10 years from first commissioning or registration. AustLII

WorkSafe Queensland audit report on 10-year major inspections

Provides evidence of compliance trends and regulatory expectations in Queensland context. WorkSafe Queensland

Mobile Crane Code of Practice 2024, WorkSafe Qld

Gives practical guidance under the WHS Act for mobile crane operations in Queensland. WorkSafe Queensland

When & How Often — Understanding the Timing

The standard “10-year” is a maximum interval when no design life is provided. If the manufacturer prescribes a shorter or different interval, that takes precedence.

For cranes with low utilisation (light duty, rarely used), some industry practitioners argue that condition-based / usage-based maintenance may be more efficient than automatic 10-year strip-downs.

However, regulatory frameworks often default to the 10-year benchmark because it is simple and measurable.

Also note: the 10-year inspection does not replace annual or periodic inspections — those must continue in between.

What the 10-Year Major Inspection Should Include (Scope & Depth)

A 10-year inspection must be far more exhaustive than normal annual checks. Here’s what it should cover:

Structural / Load-Bearing Components

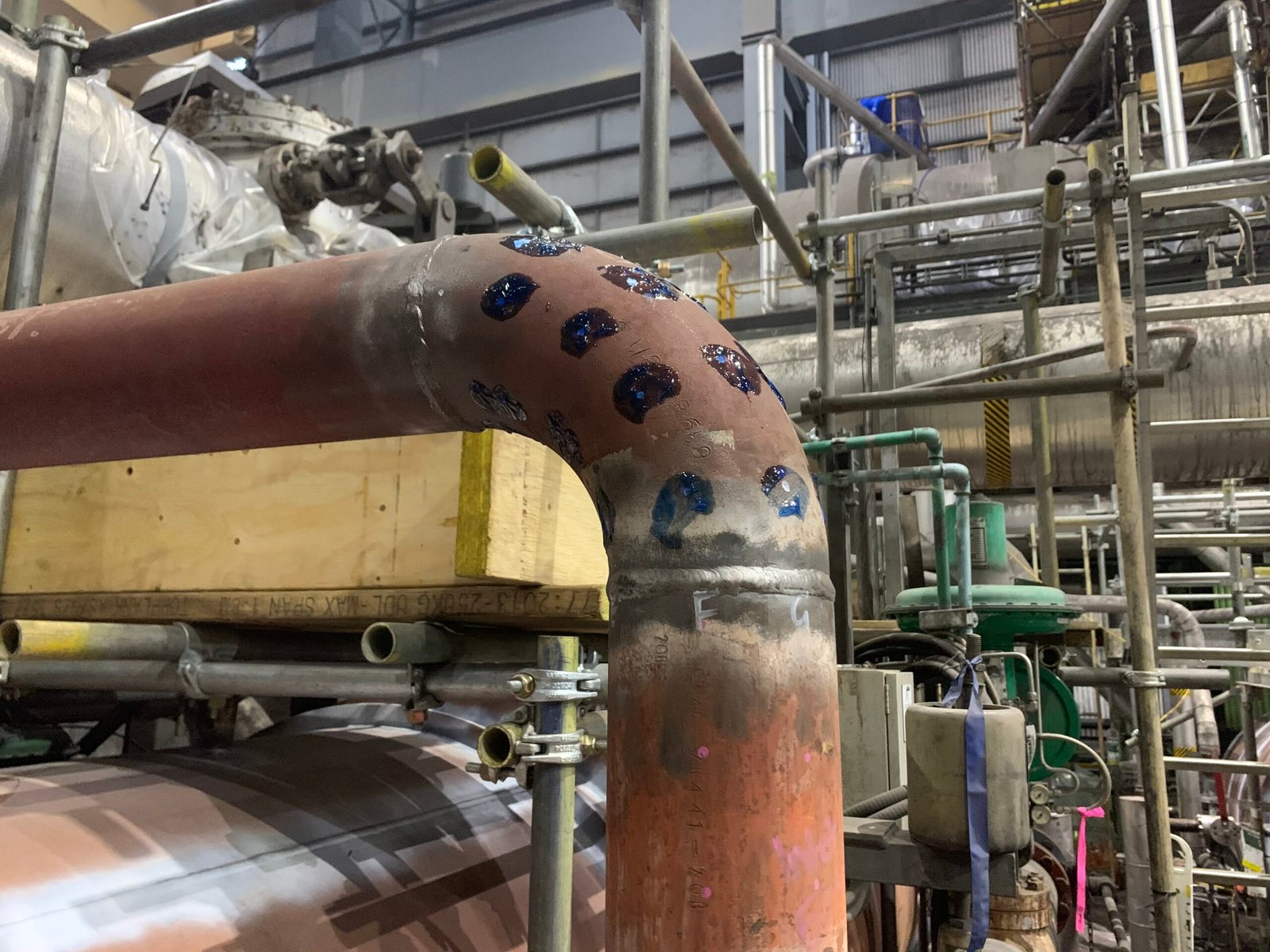

Main frame, booms, jibs, lattice structures — check for cracks, fatigue, weld defects, corrosion, deformation.

Remove coatings/paint/grease as needed to visually inspect surfaces.

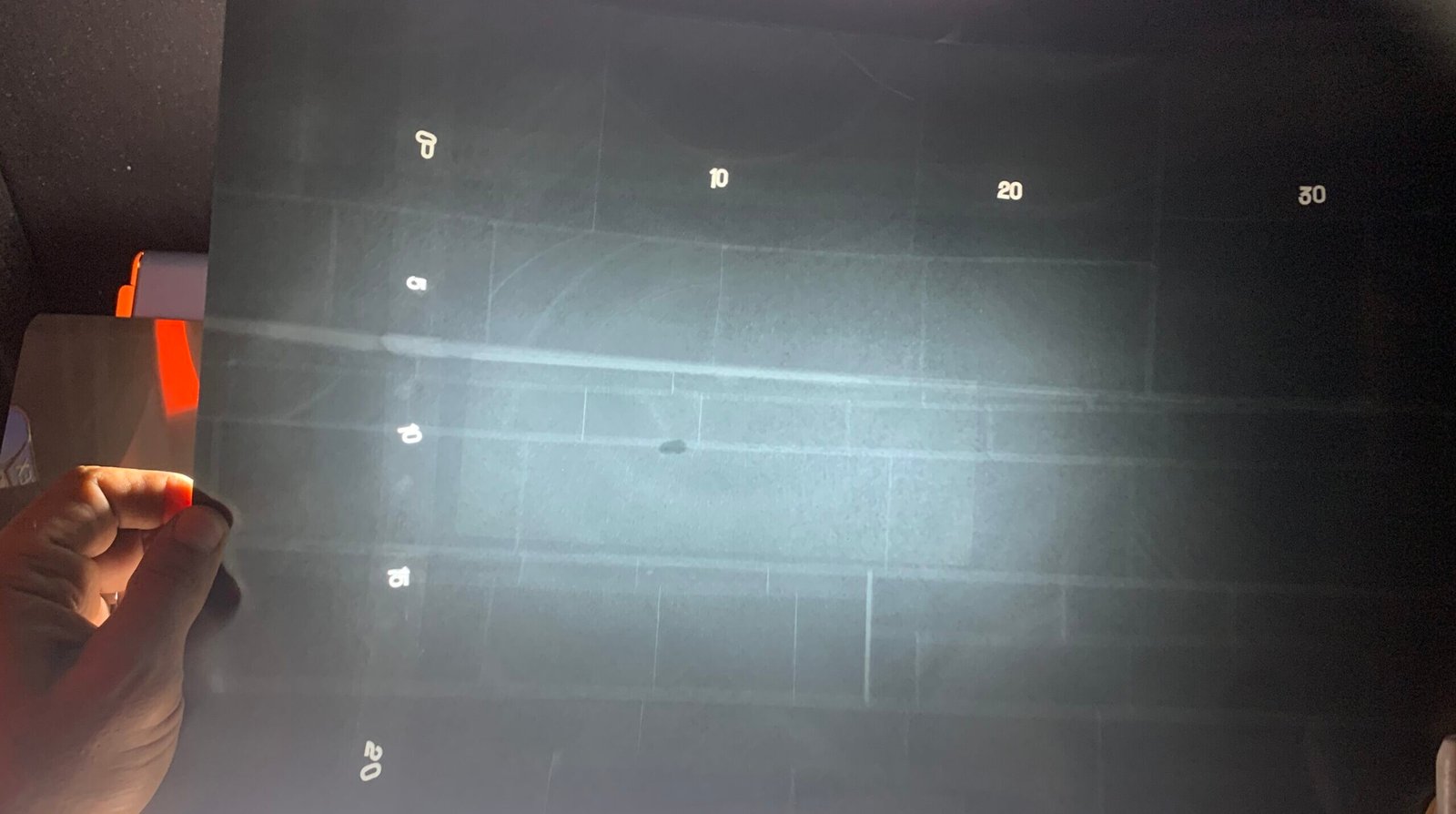

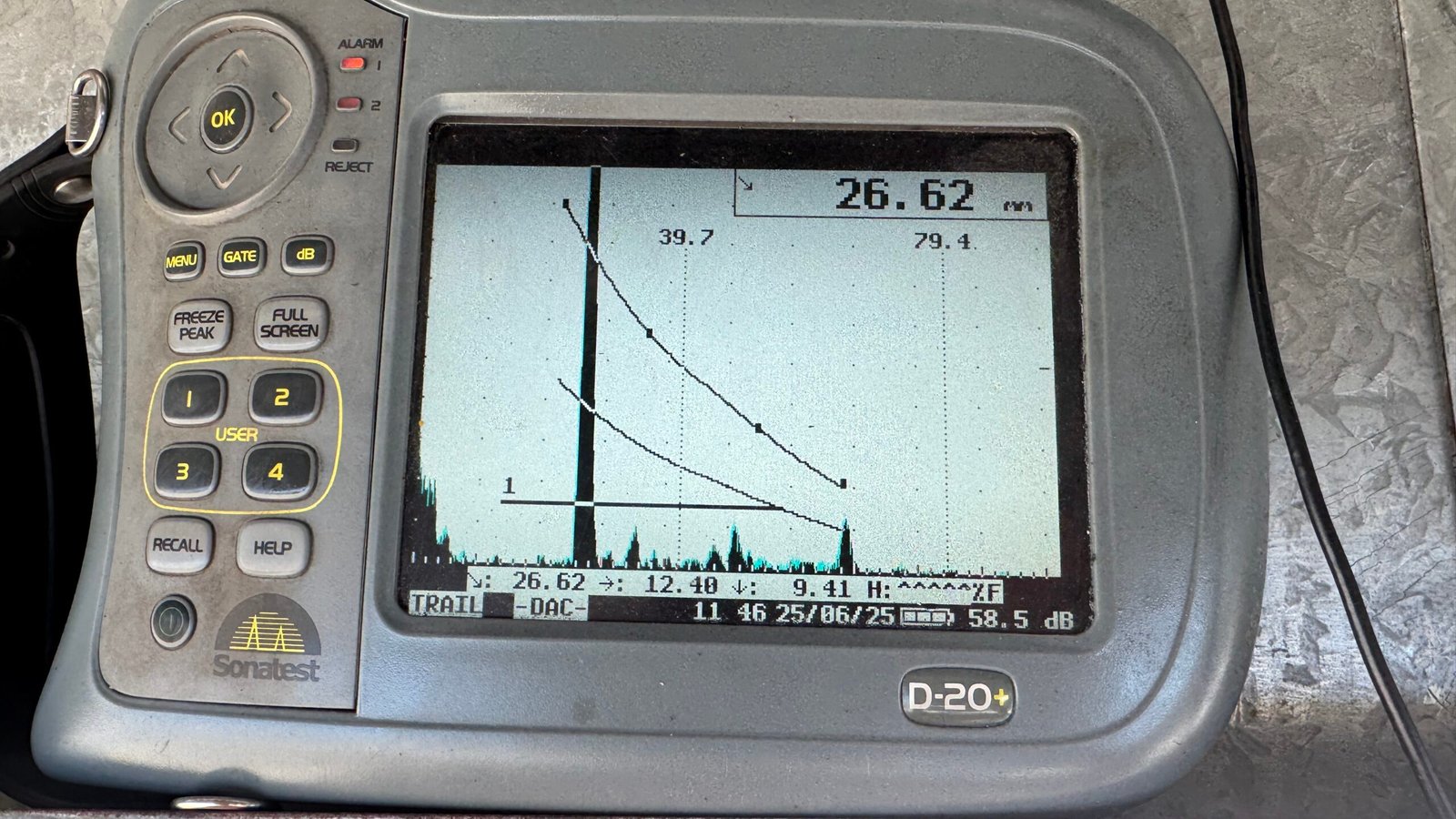

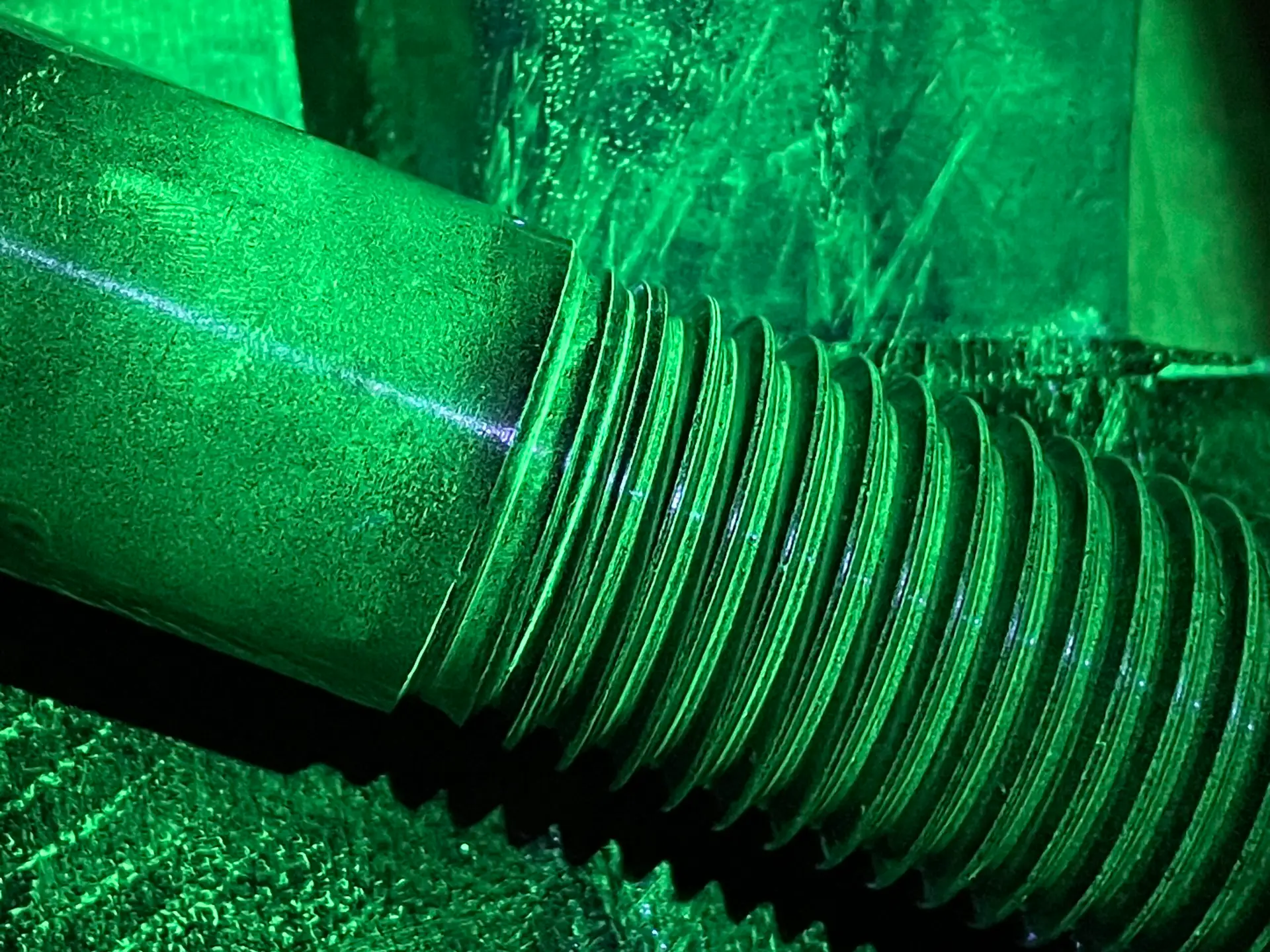

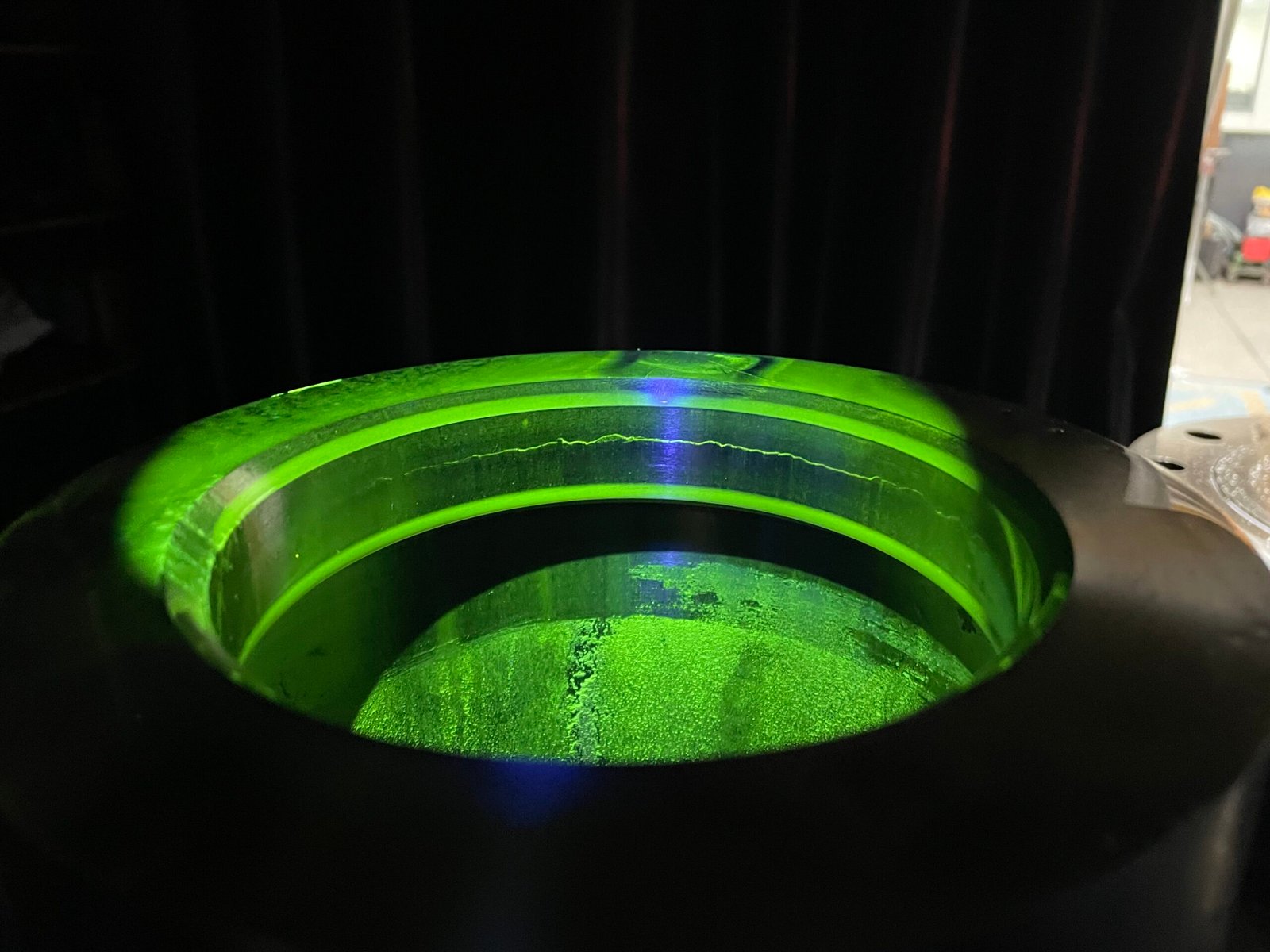

Use non-destructive testing (NDT) (e.g. dye penetrant, magnetic particle, ultrasonic) on welds, joints, critical sections.

Check fasteners (bolts, rivets), in particular high-stress joints, for damage or torque loss.

Check alignment, straightness, and geometry tolerances.

Mechanical & Moving Parts

Shafts, pins, bushes, bearings, gearboxes, couplings — inspect internal wear, clearances, lubrication.

Hoist drums, sheaves, pulleys — check for groove wear, alignment, damage.

Wire ropes, chains — check for core damage, wear, corrosion, broken strands, elongation.

Hooks, hook latches, hook throat opening measurement (within allowable tolerances).

Brakes, clutches — check for wear, adjustment, stopping performance under load.

Gearboxes, motors — open up if necessary, inspect internal gears, oil contamination, wear.

Slewing mechanism (if applicable): slew ring, bearings, teeth, lubrication.

Electrical / Control Systems

Inspect all limiting devices, load moment indicators (LMI), rated capacity indicators (RCI), safety interlocks.

Test wiring insulation, continuity, cable connections, protective devices.

Test switches, emergency stops, indicator lamps.

Inspect any control pendants, remote controls, limit switches.

Hydraulic / Pneumatic Systems (if applicable)

Cylinders, hoses, valves — inspect for leaks, internal wear, seals, performance under load.

Pressure test to ensure correct operation under rated pressure.

Load Testing & Verification

Perform test lifts using certified test weights to verify the performance of load-indicating devices and the crane’s actual capacity under safe conditions.

Compare measured loads to rated values, check safety margins.

Ancillary & Safety Items

Verify correct signage, load markings, warning labels.

Inspect access platforms, ladders, guard rails, safety cages, fall protection attachments.

Check structural supports, foundations, anchorage points (if relevant).

Inspect load blocks, hook assemblies, sheave housings, load chains, and supporting hardware.

Documentation & Service History Review

Review all previous inspection records, maintenance logs, repair history.

Cross-check that all prior defects were rectified and documented.

Identify trends in wear or recurring faults.

Reporting & Recommendations

Provide a comprehensive report with clear findings, non-conformities, recommended repairs or replacements, remaining service life estimates.

Include photographs, diagrams, measurement data, NDT results.

Include a “fitness-for-service” opinion (i.e. whether the crane is okay to continue operation or must be decommissioned/overhauled).

“Every lift tells a story — but even the strongest cranes can hide fatigue. A decade of strain deserves a detailed check. Ten-year inspections reveal what the eye can’t see and keep every lift safe.”

Who Should Conduct a 10-Year Major Inspection (Competent Person)

Because of the depth and risk involved, the inspection must be carried out by a “competent person” with relevant qualifications, ideally:

Chartered / Registered structural or mechanical engineer with specialization in lifting / crane systems

Experience in crane design, maintenance, fatigue analysis, NDT

Certifications in relevant NDT methods, crane inspection, safety systems

Knowledge of AS 2550, WHS regulations, local state WorkSafe rules

Capability to supervise dismantling, reassembly, and to interpret test data

The inspector must be able to declare fitness-for-service, decide on repairs, and understand design limits.

Step-by-Step Process / Workflow

Pre-inspection planning

• Review all history: drawings, prior reports, maintenance logs

• Identify scope, parts to remove, safety plan

• Arrange tooling, test weights, NDT equipment, scaffolding, permits

De-energize / Lock-out / Safety setup

• Isolate power, hydraulics, tag out controls

• Safe scaffolding, lighting, fall-arrest systems

Disassembly & stripping

• Remove paint/coating, grease, corrosion covering critical zones

• Dismantle components (gearboxes, wheels, covers) as required

Inspection & NDT

• Visual checks on all parts

• Non-destructive testing (welds, cracks)

• Dimensional measurements, clearances

Mechanical / Internal checks

• Open gearboxes, inspect gear teeth, bearings, lubrication

• Inspect hoist drums, rope reeving, sheaves, pins

Load / Functional Testing

• Reassemble for test lifts

• Perform calibrated test load lifts, measure indicator accuracy

• Exercise full function envelope under load

Reassembly & Adjustments

• Ensure torqueing of bolts, alignment, tolerances

• Final mechanical / electrical checks

Documentation & Report

• Create formal report: observations, measurements, repairs needed

• Include recommendations, photos, future intervals

Rectification & Follow-Up

• Owner/operator acts on recommendations

• Follow-up inspection on repaired parts

Record Retention & Certification

• Store reports, test certificates

• Provide certificate / statement of compliance

Common Issues, Risks & What to Watch Out For

Hidden fatigue cracks in welds or high-stress zones

Bolt loosening or fatigue failure (especially in tension joints)

Severely corroded or pitted structural steel

Excessive wear internal to gearboxes or bearings (hard to detect without opening)

Wire rope core damage or broken strands not visible externally

Misalignment, binding, bearing play

Failed or inaccurate load-limiting devices or indicators

Electrical insulation degradation or connections loosening

Hydraulic leaks, seal failures under stress

Poor previous repair work or patches

Inadequate rectification of earlier defects

Underestimating downtime and logistical complexity